In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Spesifikaasjes

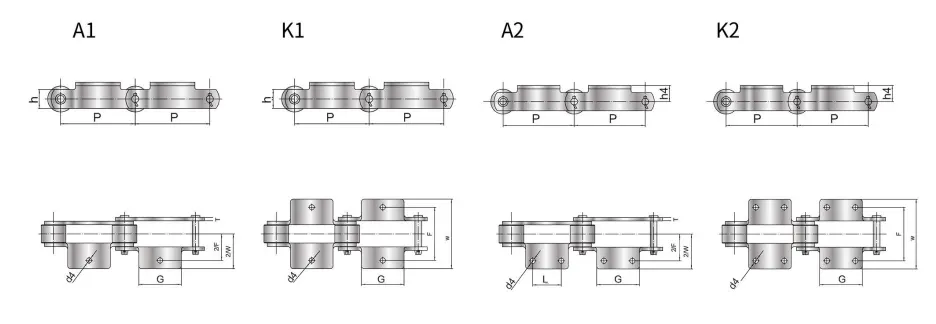

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204 has the following parameters:

- Chain type: RF Type Conveyor Chain

- Attachments: A1, K1, A2, K2

- Chain model: RF204

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

Ynlieding

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204 is a highly durable and reliable conveyor chain that is widely used in various industries such as automotive, food and beverage, and material handling. This chain is designed to withstand heavy loads and extreme environments, ensuring smooth and efficient operation for your applications.

Spesifikaasjes

Chain Dimensions

- Chain Pitch: 38.10 mm

- Plate Height: 44.45 mm

- Pin Diameter: 11.90 mm

- Maximum Allowable Load: 26.50 kN

Attachment Dimensions

- A1 Attachment: 15.88 mm

- K1 Attachment: 22.20 mm

- A2 Attachment: 15.88 mm

- K2 Attachment: 22.20 mm

Features and Benefits

High Strength

The RF Type Conveyor Chain is made of high-quality materials, providing excellent strength and durability. The chain is able to withstand heavy loads and high-speed operation, ensuring a long service life and reducing downtime and maintenance costs.

Smooth Operation

The chain is designed with precision components, ensuring smooth and efficient operation even under high stress conditions. This helps to reduce wear and tear on the chain and other components, extending the service life of your equipment and reducing maintenance costs.

Versatile Applications

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204 is suitable for a wide range of applications, including material handling, food and beverage processing, automotive manufacturing, and more. This makes it a versatile and cost-effective solution for your conveyor needs.

Easy Maintenance

The chain features a simple design that makes it easy to maintain and repair. In addition, the chain can be easily disassembled and reassembled, simplifying the maintenance process and reducing downtime.

Customizable

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204 can be customized to meet your specific requirements, including different attachment configurations and chain lengths. This ensures that you get the right chain for your application, maximizing efficiency and productivity.

Konklúzje

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204 is a high-quality and reliable conveyor chain that offers a range of features and benefits to enhance your application efficiency and productivity. With its high strength, smooth operation, versatile applications, easy maintenance, and customizable options, this chain is an excellent choice for your conveyor needs.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. Our company takes pride in offering the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204, which highlights the unique selling points that set us apart. We prioritize product quality, exceptional service, and showcase our strong manufacturing capabilities.

Our stainless steel roller chains are designed with precision and engineered to deliver unrivaled performance. With a focus on durability and reliability, our chains are built to withstand even the toughest conditions, ensuring seamless operations in various industries.

At RP Techniek BV, we understand the importance of providing a wide range of options to meet our customers' diverse needs. Along with the RF Type Conveyor Chain, we offer a variety of other stainless steel roller chains for sale. Whether you require chains for industrial applications, manufacturing processes, or specialized machinery, we have the solution for you.

By choosing our stainless steel roller chains, you can expect superior quality, exceptional customer support, and reliable performance. Join our satisfied customers today and experience the difference.

Sprockets for Sale

If you are looking for the perfect match of chain sprockets for your RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF204, you have come to the right place! We offer a wide range of high-quality sprockets that will meet your exact requirements.

Our chain sprockets are made with high-grade materials and are designed to be long-lasting, reliable and efficient. They are available in various sizes and configurations, making it easy for you to find the perfect match for your conveyor system.

Whether you need a sprocket with a specific number of teeth, a custom bore size, or a special coating for corrosion resistance, we have got you covered. Our team of experts will work with you closely to understand your needs and provide you with the best solution possible.

Contact us today to learn more about our chain sprockets and how we can help you get the most out of your conveyor system.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...