In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Spesifikaasjes

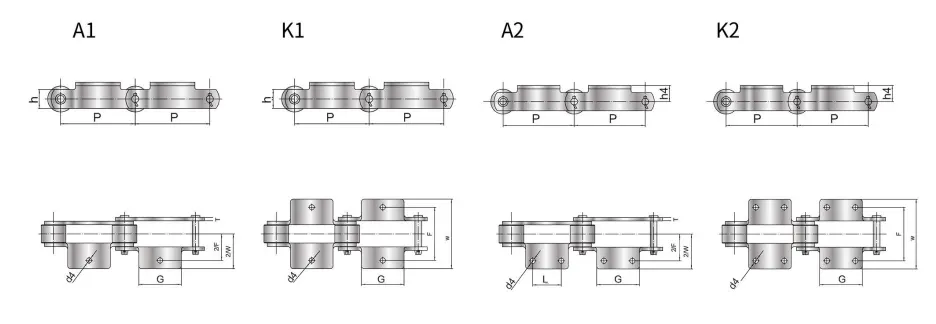

This RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200 has the following parameters:

- Parameter 1:

- Parameter 2:

- Parameter 3:

- Parameter 4:

Please note that the specifications may vary based on the specific requirements and usage of the chain.

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

1. Introduction

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200 is a highly durable and versatile conveyor chain designed for various industrial applications. With its innovative design and high-quality materials, this conveyor chain offers excellent performance and reliability.

2. Features

2.1 Robust Construction

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200 features a robust construction that can withstand heavy loads and extreme operating conditions. Its strong and durable components ensure long-lasting performance in demanding environments.

2.2 Enhanced Efficiency

Equipped with A1, K1, A2, and K2 attachments, this conveyor chain offers enhanced efficiency in material handling processes. The attachments allow for secure and stable transportation of various products, increasing productivity and reducing downtime.

2.3 Superior Wear Resistance

The conveyor chain is made from high-quality materials that provide excellent wear resistance. This ensures minimal wear and tear even in high-speed and high-impact applications, resulting in extended chain life and reduced maintenance costs.

3. Applications

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200 is suitable for various industries and applications, including:

3.1 Automotive Industry

Used in automotive assembly lines for transporting car components and assemblies.

3.2 Food Processing Industry

Ideal for conveying food products, such as bottles, cans, and packaged goods, in food processing plants.

3.3 Packaging Industry

Efficiently transports packaged products, boxes, and cartons in packaging facilities.

4. Installation and Maintenance

4.1 Proper Installation

Ensure the conveyor chain is correctly installed, following the manufacturer's guidelines and specifications. This will maximize its performance and prevent premature wear.

4.2 Regular Lubrication

Regularly lubricate the conveyor chain to reduce friction and prevent excessive wear. Use a high-quality lubricant recommended by the manufacturer for optimal results.

4.3 Routine Inspection

Perform routine inspections to identify any signs of wear or damage. Replace any worn-out or damaged components promptly to maintain the chain's performance and prevent unexpected breakdowns.

4.4 Proper Tensioning

Ensure the conveyor chain is correctly tensioned to prevent slack or excessive tension. Improper tension can lead to premature wear and reduced chain life.

5. Conclusion

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200 is a reliable and efficient solution for material handling applications. With its robust construction, enhanced efficiency, and superior wear resistance, this conveyor chain delivers optimal performance and longevity. Suitable for various industries, it offers seamless and secure transportation of products, contributing to increased productivity and operational efficiency.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We pride ourselves on offering the exceptional RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200, which showcases our unique selling points and highlights the superior quality and service we provide. With our strong manufacturing capabilities, we ensure that our stainless steel roller chains meet the highest standards.

In addition to our featured product, we also offer a wide range of other stainless steel roller chains for sale. Whether you need chains for industrial applications, machinery, or any other specific requirements, we have you covered. Our diverse selection ensures that you can find the perfect chain to suit your needs.

Sprockets for Sale

When it comes to RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200, finding the perfect sprocket pairing is crucial for smooth operation. At our company, we offer a wide range of sprockets to suit your needs.

Our selection includes various types of sprockets, each designed to provide optimal performance and durability. Whether you require a standard sprocket or a custom-made one, we have you covered. With our extensive inventory, you can find the right sprocket to match the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17200 effortlessly.

Our sprockets are crafted from high-quality materials, ensuring long-lasting functionality even in demanding applications. We understand the importance of reliable and efficient conveyor systems, and our sprockets are engineered to meet those requirements.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...