In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications for MC224SS MC Series Stainless Steel Hollow Pin Chain

- Material: Stainless Steel

- Pitch: 1.5 inches

- Pin Diameter: 0.437 inches

- Inner Width: 0.687 inches

- Breaking Load: 10,400 pounds

- Weight per Foot: 2.42 pounds

| Chain No. | Pitch | Roller diameter |

Bush diameter |

Plate depth |

width between inner plates |

pin diameter | pin length |

Plate thickness |

Breaking load |

Breaking load |

||||||||||

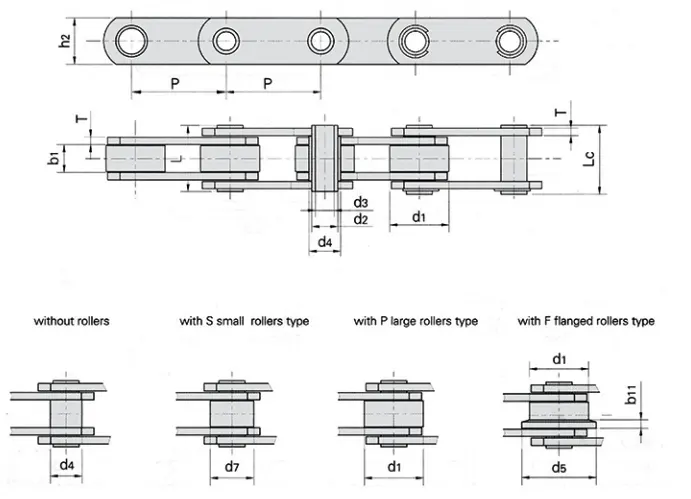

| P(mm) | P(mm) | P(mm) | P(mm) | P(mm) | P(mm) | d1 max (mm) |

d7 max (mm) |

d5 max (mm) |

b11 (mm) |

d4 max (mm) |

h2 max (mm) |

b1 min (mm) |

d2 min (mm) |

d3 min (mm) |

L max (mm) |

Lc max (mm) |

T max (mm) |

Q min (KN/LB) |

*Q min (KN/LB) |

|

| MC28SS | 63 | 80 | 100 | 125 | 160 | 36 | 25 | 45 | 4.5 | 17.5 | 25 | 20 | 13 | 8.2 | 36 | 38.5 | 3.5 | 19.6/4454.8 | 28/6363.7 | |

| MC56SS | 80 | 100 | 125 | 160 | 200 | 250 | 50 | 30 | 60 | 5 | 21 | 35 | 24 | 15.5 | 10.2 | 45 | 47.5 | 4 | 39.2/8908.9 | 63/14317.8 |

| MC112SS | 100 | 125 | 160 | 200 | 250 | 315 | 70 | 42 | 85 | 7 | 29 | 50 | 32 | 22 | 14.3 | 62.5 | 64.3 | 6 | 78.4/17817.8 | 126/28635.6 |

| MC224SS | 160 | 200 | 250 | 315 | 400 | 500 | 100 | 60 | 120 | 10 | 41 | 70 | 43 | 31 | 20.3 | 83 | 85.5 | 8 | 156.8/35636.3 | 245/55680.8 |

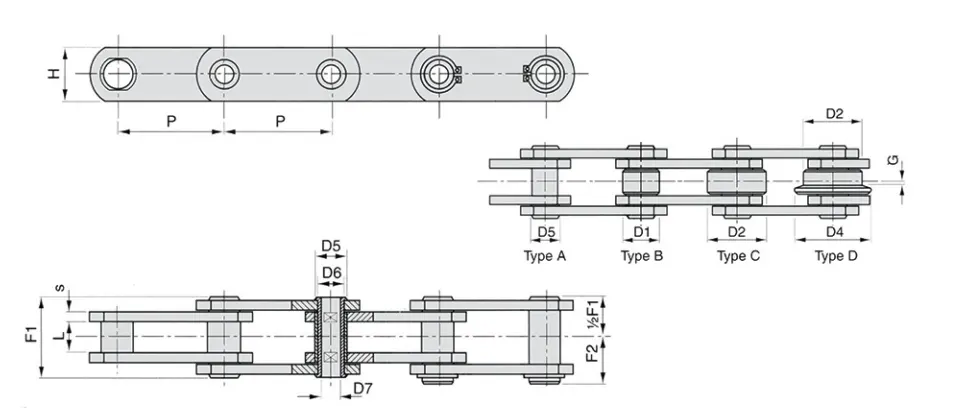

| Chain No. |

P | L | D1 | D2 | D4 | G | D5 | D6 | D7 | H | S | F1 | F2 | Breaking (load kN) |

Mass Type C (kg/m) |

| MC28SS | 50 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 4.3 |

| MC28SS | 63 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 3.8 |

| MC28SS | 80 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 3.2 |

| MC28SS | 100 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 2.8 |

| MC28SS | 125 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 2.5 |

| MC56SS | 63 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 8.5 |

| MC56SS | 80 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 7.2 |

| MC56SS | 100 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 6.2 |

| MC56SS | 125 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 5.4 |

| MC56SS | 160 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 4.7 |

| MC112SS | 80 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 16.6 |

| MC112SS | 100 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 14 |

| MC112SS | 125 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 11.2 |

| MC112SS | 160 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 10.2 |

| MC112SS | 200 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 8.9 |

| MC112SS | 250 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 156.8 | 7.9 |

| MC224SS | 125 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 32.3 |

| MC224SS | 160 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 27.1 |

| MC224SS | 200 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 23.5 |

| MC224SS | 250 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 20.6 |

| MC224SS | 315 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 17.2 |

MC224SS MC Series Stainless Steel Hollow Pin Chain

Title 1: Overview of MC224SS MC Series Stainless Steel Hollow Pin Chain

The MC224SS MC Series Stainless Steel Hollow Pin Chain is a high-quality chain designed for various industrial applications. With its durable stainless steel construction and unique hollow pin design, this chain offers exceptional performance and reliability in demanding environments.

Title 2: Features and Benefits

High Strength and Durability

The MC224SS MC Series Stainless Steel Hollow Pin Chain is made from premium stainless steel, providing excellent strength and durability. It can withstand heavy loads and resist corrosion, ensuring a long service life even in harsh conditions.

Easy Installation and Maintenance

This chain is designed for easy installation and maintenance. The hollow pin design allows for quick and hassle-free attachment of accessories, reducing downtime and increasing productivity.

Smooth and Quiet Operation

The MC224SS MC Series Chain features precision manufacturing and a unique pin design, resulting in smooth and quiet operation. This ensures minimal noise and vibration, creating a comfortable working environment.

Versatile Application

With its robust construction and reliable performance, the MC224SS MC Series Chain is suitable for various applications, including conveying systems, packaging equipment, and food processing machinery.

Customizable Options

This chain can be customized to meet specific requirements. Optional attachments, coatings, and lubrication are available to enhance performance and adapt to different operating conditions.

Title 3: Technical Specifications

- Chain Type: MC Series

- Material: Stainless Steel

- Pitch: [Insert pitch value]

- Inner Width: [Insert inner width value]

- Chain Length: [Insert chain length value]

- Working Load: [Insert working load value]

- Temperature Range: [Insert temperature range]

Title 4: Applications

The MC224SS MC Series Stainless Steel Hollow Pin Chain is widely used in the following industries:

- Food and beverage

- Automotive

- Ferpakking

- Pharmaceutical

- Chemical

Title 5: Conclusion

The MC224SS MC Series Stainless Steel Hollow Pin Chain is a top-quality chain that offers exceptional strength, durability, and versatility. Its unique hollow pin design and stainless steel construction make it ideal for various industrial applications. With customizable options and easy installation, this chain provides a reliable and efficient solution for your conveying and processing needs. Invest in the MC224SS MC Series Stainless Steel Hollow Pin Chain and experience superior performance and longevity.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We take pride in offering high-quality stainless steel roller chains, including the MC224SS MC Series Stainless Steel Hollow Pin Chain, which is one of our unique selling points.

Our stainless steel roller chains are built to last. They are made with premium quality materials to ensure durability, strength, and resistance to corrosion. We understand that our customers need reliable products, and that is what we deliver.

In addition to offering top-quality products, we are also committed to providing exceptional customer service. Our team of experts is always ready to assist our clients with any questions or concerns they may have.

As for our production capabilities, we have state-of-the-art facilities and a highly skilled workforce that specializes in producing high-quality stainless steel roller chains. We have strict quality control procedures in place to ensure that every product leaving our factory meets the highest standards.

Apart from the MC224SS chain, we also offer a wide range of other types of stainless steel roller chains for our clients to choose from. No matter what your needs are, we have a product that will meet your requirements.

Please refer to the image below for a glimpse of our manufacturing facility:

Sprockets for Sale

The MC224SS MC Series Stainless Steel Hollow Pin Chain is a high-quality chain that requires an appropriate sprocket for optimal performance. At our company, we provide a wide range of sprockets that are suitable for this chain and other chains as well. Our sprockets are made from high-quality materials and are designed with precision to ensure maximum durability and efficiency.

We offer various types of sprockets, including roller chain sprockets, engineering class sprockets, and specialty sprockets. Our sprockets come in different sizes and tooth counts to suit your needs. Whether you need a small sprocket for a lightweight application or a large sprocket for a heavy-duty application, we have got you covered.

Our sprockets are compatible with different types of chains, including ANSI, BS, DIN, and ISO chains. They are suitable for various applications, such as conveyors, agriculture, mining, and many more.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...