The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

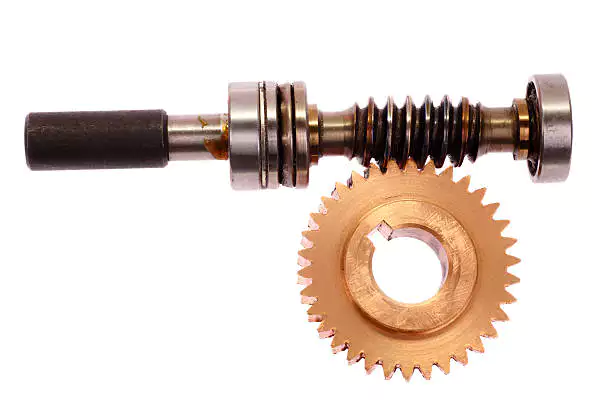

Hollow Worm Gear

The Hollow Worm Gear is an essential mechanical component designed for efficient torque transmission. Made from high-quality alloy steel, it ensures durability and strength. This innovative Hollow Worm Gear reduces friction and enhances performance in various applications, making it ideal for precision machinery and automotive systems.

Details of Hollow Worm Gear

| Parameter | Spesifikaasje |

|---|---|

| Gear Ratio | 10:1 |

| Materiaal | Aluminum Alloy |

| Load Capacity | 500 Nm |

| Operating Temperature | -20°C to +80°C |

| Lubrication Type | Grease |

| Effisjinsje | 90% |

Features of Hollow Worm Gear

- Lightweight Design: The Hollow Worm Gear is designed to be lightweight, which reduces the overall weight of machinery while maintaining strength and durability. This makes it ideal for applications where weight is a concern.

- High Efficiency: With its unique design, the Hollow Worm Gear provides high efficiency in power transmission, minimizing energy losses and maximizing performance in various mechanical systems.

- Compact Size: The hollow structure allows for a more compact size compared to traditional worm gears, facilitating easier integration into tight spaces within machinery.

Applications of Hollow Worm Gear in Mechanical Systems

The Hollow Worm Gear is an essential component in various mechanical applications, providing efficient power transmission and space-saving design. Its unique structure allows for enhanced torque output while minimizing weight, making it ideal for use in robotics, conveyors, and automated machinery. The Hollow Worm Gear also offers excellent durability and low maintenance, ensuring long-term performance in demanding environments. By integrating this advanced gear system, engineers can optimize their designs for improved efficiency and reliability.

Manufacturing Process of Hollow Worm Gear

- Material Selection: The first step in the manufacturing process of Hollow Worm Gear is selecting the appropriate materials. Generally, high-quality steel or bronze is used due to their strength and durability. These materials are chosen to ensure that the Hollow Worm Gear can withstand high loads and stresses during its operation. The right material selection not only enhances the performance of the gear but also extends its lifespan, making it a reliable choice for various applications.

- Machining: Once the materials are selected, the next stage is machining the Hollow Worm Gear. This involves cutting the material into the desired shape and size using advanced CNC machines. Precision is critical during this phase, as even minor inaccuracies can affect the gear's performance. The machining process includes creating the worm shaft and the gear teeth, ensuring they are perfectly aligned for smooth operation.

- Heat Treatment: After machining, the Hollow Worm Gear undergoes heat treatment to enhance its mechanical properties. This process involves heating the gear to a specific temperature and then cooling it rapidly. Heat treatment increases the hardness and strength of the gear, making it more resistant to wear and fatigue. This step is essential for ensuring that the Hollow Worm Gear can perform efficiently under various operational conditions.

- Finishing: The final step in the manufacturing of Hollow Worm Gear is the finishing process. This includes grinding and polishing the gear to achieve the desired surface finish. A smooth surface reduces friction and improves the efficiency of the gear's operation. This step is vital for ensuring that the Hollow Worm Gear operates quietly and effectively, contributing to the overall performance of the machinery it is used in.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands and is recognized as one of the top ten worm gear suppliers in the country.

Hollow Worm Gear

- Our products feature top-notch quality and durability, ensuring reliable performance in various applications.

- We pride ourselves on using advanced manufacturing techniques to produce hollow worm gears that meet high industry standards.

- Our company's strength lies in our extensive experience and expertise in the field, allowing us to cater to a wide range of customer needs.

- We offer exceptional customer service, providing support and guidance throughout the purchasing process and beyond.

Oanfoljende ynformaasje

| Edited | Zqq |

|---|

Blogs Updated

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...