In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details

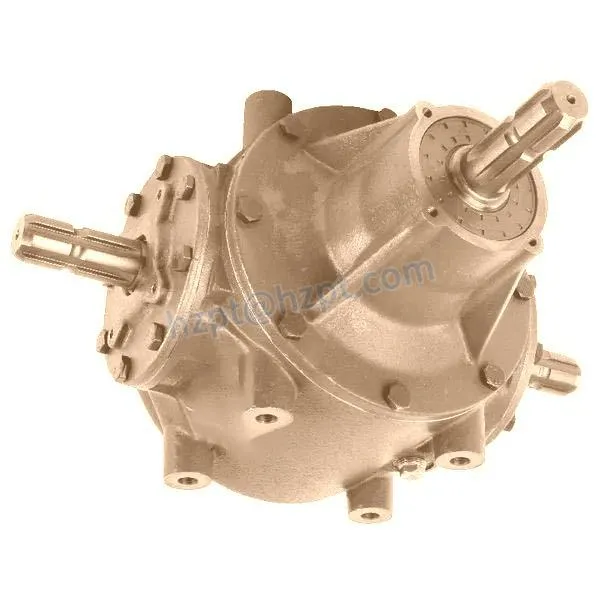

The Flail Mower Gearboxes - Replacement of Comer Code T-269B 1:1.93 has the following specifications:

- Model: Flail Mower Gearboxes - Replacement of Comer Code T-269B 1:1.93

- Ratio: 1:1.93

| Produkt Beskriuwing |

Flail Mower Gearboxes - Replacement of Comer Gearbox T-269B 1:1.93

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

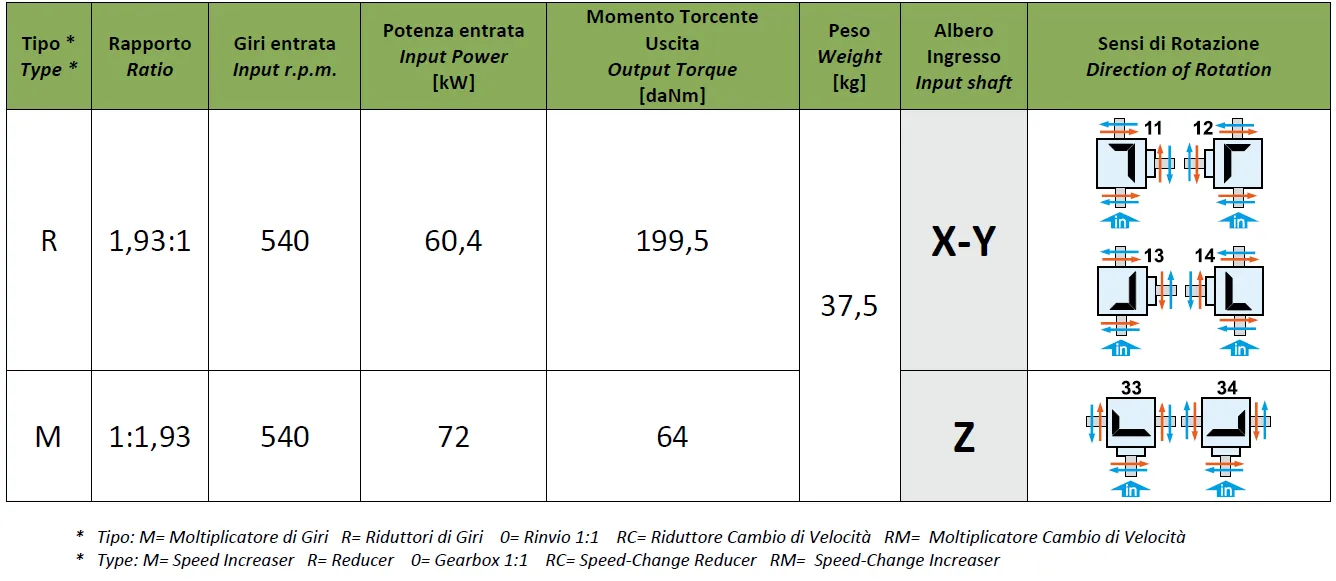

| Max. output torque |

199.5?daNm

|

| Contains oil |

No

|

| Max. oil capacity |

3.3?l

|

| Max. oil change interval |

500?h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Gewicht |

37.5 kg

|

| Gear arrangement Increasing |

33 - 34

|

| Gear arrangement Reducing |

11 - 12 - 13 - 14

|

| Input power kW / HP Increasing |

72.1 / 98?kW/HP

|

| Input shaft Increasing |

Z

|

| Input shaft Reducing |

X - Y

|

| Input power KW / HP Reducing |

60.4 / 82 kW/HP

|

| Output Torque DaNm Increasing |

64?daNm

|

| Ratio Increasing |

1: 1.93

|

| Ratio Reducing |

1.93: 1

|

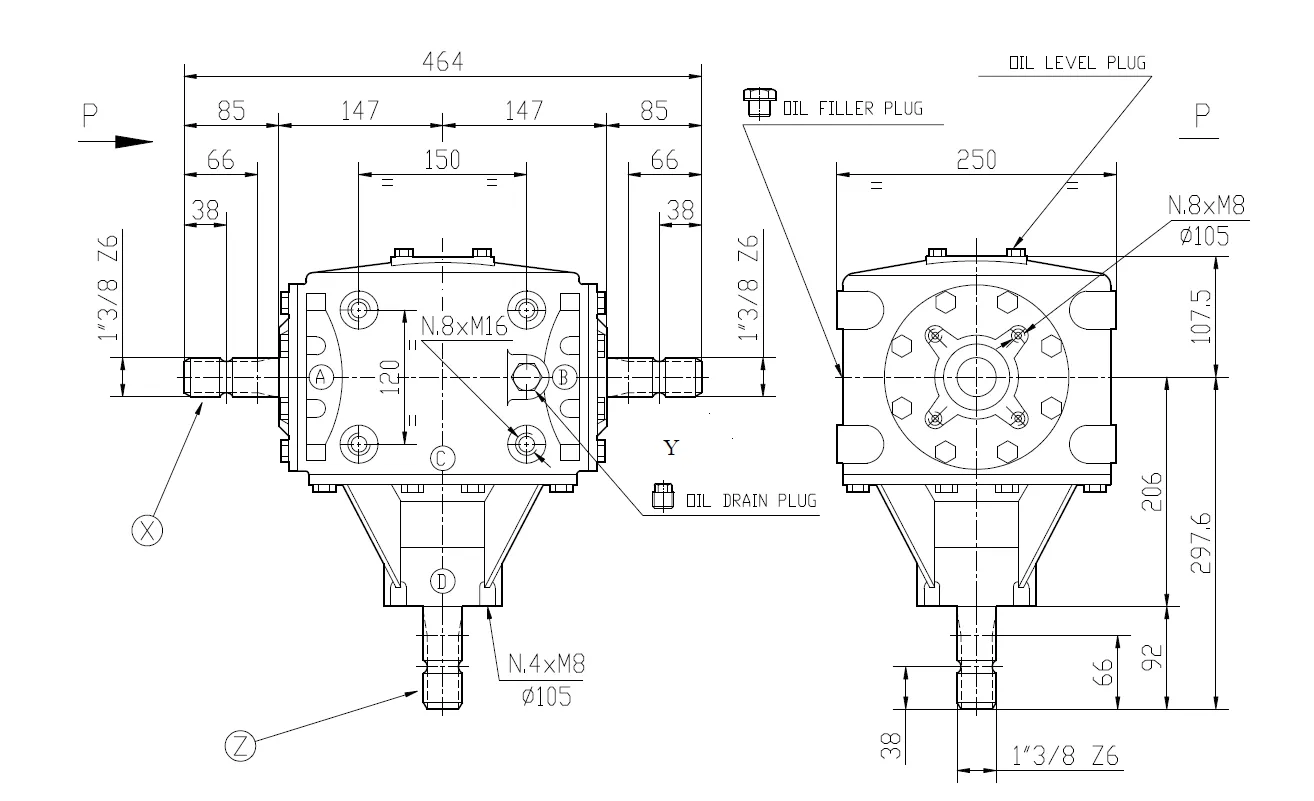

| Shaft X |

1 3/8" (6) (A)

|

| Shaft Y |

1 3/8" (6) (A)

|

| Shaft Z |

1 3/4" (6)

|

Ynlieding

Welcome to our comprehensive guide on Flail Mower Gearboxes. In this article, we will discuss the replacement of the highly sought-after Comer Code T-269B 1:1.93 gearbox. Whether you are a professional in the agriculture industry or a passionate gardening enthusiast, understanding the intricacies of flail mower gearboxes is essential for optimal performance and durability.

1. Understanding Flail Mower Gearboxes

Before we delve into the specifics of the Comer Code T-269B 1:1.93 gearbox replacement, let's first gain a thorough understanding of flail mower gearboxes in general. Flail mower gearboxes serve as the vital component responsible for transmitting power from the tractor to the flail mower blades. They are designed to endure high torque, enabling efficient cutting and shredding of vegetation.

2. The Importance of Comer Code T-269B 1:1.93 Gearbox

The Comer Code T-269B 1:1.93 gearbox is widely recognized for its superior performance and reliability. Its precise gear ratio of 1:1.93 ensures optimal power transmission, resulting in efficient and smooth operation of flail mowers. This gearbox is specifically designed to withstand heavy loads and demanding working conditions, making it an ideal choice for professional farmers and landscapers.

3. Signs for Gearbox Replacement

Over time, flail mower gearboxes may require replacement due to wear and tear or accidental damage. Here are some common signs that indicate the need for a gearbox replacement:

- Excessive noise or vibrations during operation

- Leakage of lubricating oil

- Reduced cutting efficiency

- Inconsistent blade rotation

4. The Replacement Process

Replacing the Comer Code T-269B 1:1.93 gearbox requires careful attention to detail and adherence to proper procedures. Here is a step-by-step guide to help you through the replacement process:

- Remove the flail mower from the tractor and ensure it is safely secured

- Disconnect the power take-off shaft and hydraulic connections

- Unbolt the old gearbox from the flail mower frame

- Carefully install the new Comer Code T-269B 1:1.93 gearbox and secure it tightly

- Reconnect the power take-off shaft and hydraulic connections

- Ensure all connections are properly tightened and lubricate the gearbox as per manufacturer recommendations

- Reattach the flail mower to the tractor and conduct a thorough test to ensure proper functionality

5. Maintenance and Care

Maintaining and caring for your flail mower gearbox is crucial for prolonging its lifespan and ensuring optimal performance. Here are some tips to keep your gearbox in top condition:

- Regularly inspect the gearbox for any signs of damage or wear

- Keep the gearbox properly lubricated, following the manufacturer's guidelines

- Clean the gearbox after each use to remove debris and prevent clogging

- Store the flail mower in a dry and sheltered area when not in use

6. Conclusion

In conclusion, the replacement of the Comer Code T-269B 1:1.93 gearbox is a vital aspect of maintaining the optimal performance of your flail mower. By following the proper replacement process and implementing regular maintenance, you can ensure that your flail mower remains efficient and reliable for years to come. Invest in the superior quality of the Comer Code T-269B 1:1.93 gearbox, and experience the difference in your agricultural or gardening endeavors.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV, as the authorized sales agent of Ever-power Group in the Netherlands, offers a range of high-quality agricultural gearboxes. One of our standout products is the Flail Mower Gearbox - Replacement of Comer Code T-269B 1:1.93.

Our gearboxes are known for their exceptional performance and durability. We prioritize the quality of our products, ensuring that they can withstand the demanding conditions of agricultural operations. Additionally, we take pride in providing excellent customer service, offering support and assistance to our clients whenever needed.

With a strong manufacturing capability, we ensure that our gearboxes are manufactured using advanced technology and strict quality control measures. This allows us to consistently deliver gearboxes that meet and exceed customer expectations.

Apart from gearboxes, we also offer a wide range of other agricultural machinery parts and transmission components. Our extensive selection ensures that our customers have access to a variety of options for their specific needs.

Please find below an image showcasing our agricultural gearbox manufacturing capabilities:

PTO Shafts for Agricultural Gearboxes

When it comes to agricultural machinery, PTO shafts or Power Take-Off shafts play a crucial role in transmitting power from the tractor to the attached equipment. The gearbox is a central component that connects the PTO shaft to the agricultural implements. Gearboxes provide the necessary speed reduction and increase the torque to achieve the desired output.

If you are looking for replacement PTO shafts for your agricultural gearbox, then look no further than our company. We offer a wide range of PTO shafts that are suitable for various agricultural applications. Our PTO shafts are engineered to deliver high performance and durability, ensuring that your equipment operates efficiently and reliably.

One of our popular products is the PTO shaft replacement for Comer Code T-269B 1:1.93 used in Flail Mower Gearboxes. Our replacement PTO shafts are designed to meet or exceed the OEM specifications, ensuring a perfect fit and high-quality performance. Additionally, our PTO shafts are made from high-grade materials, making them tough enough to withstand the harsh conditions of agriculture.

We understand that downtime can be costly in the agricultural industry, and that's why we strive to provide our customers with quick and reliable services. We have a wide inventory of PTO shafts readily available for shipment. Whether you need a standard PTO shaft or a custom-made one, we can deliver it to you quickly and efficiently.

In conclusion, if you are in need of reliable and durable PTO shafts for your agricultural gearbox, then don't hesitate to contact us. We are committed to providing our customers with the best quality products and services that meet their needs.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...