In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details

The Flail Mower Gearbox - Replacement of Comer Code L25J 1:1.9 has the following details:

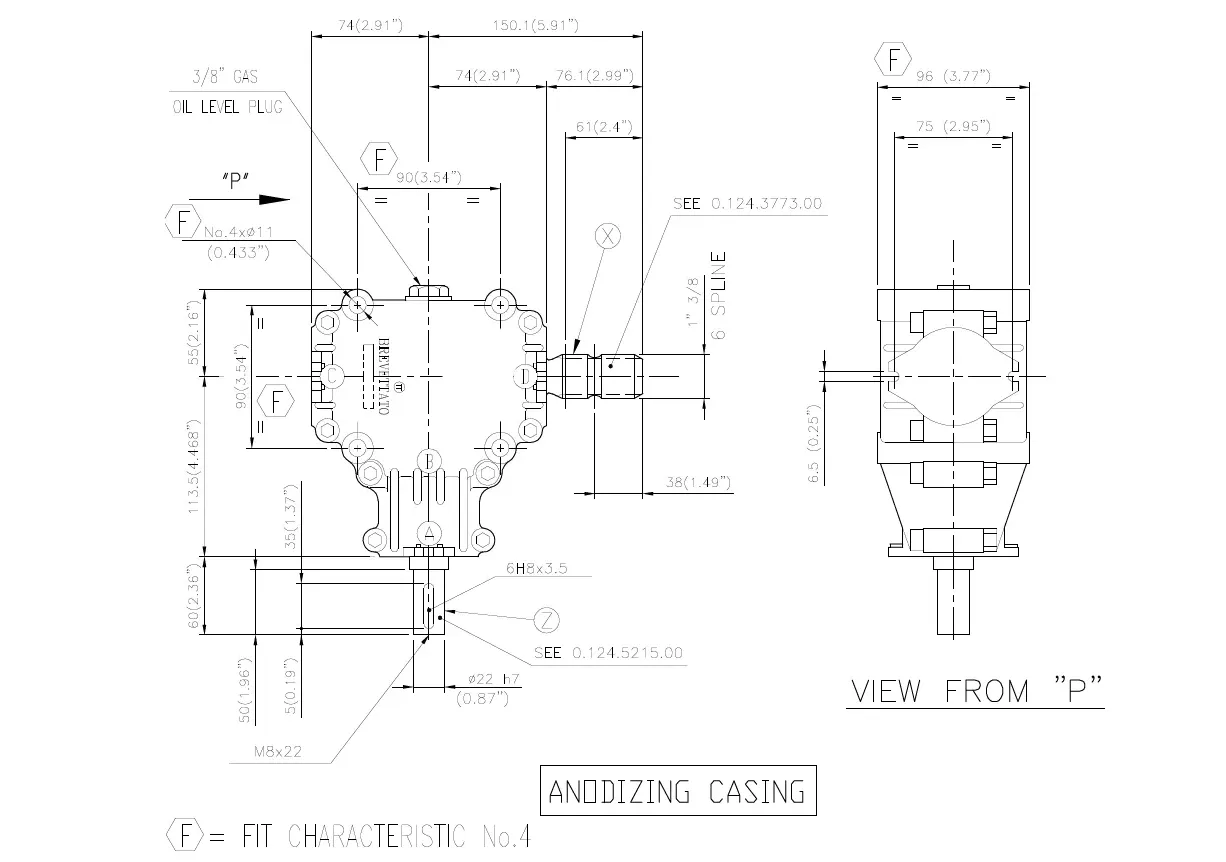

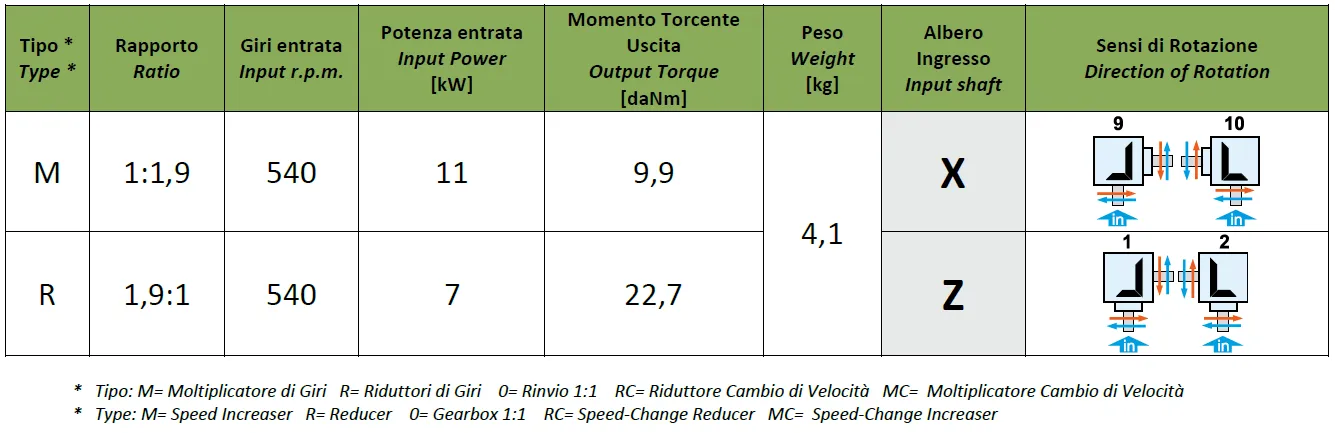

- Ratio: 1:1.9

- Replacement for Comer Code L25J

- Designed for use on flail mowers

| Description |

?Flail Mower Gearbox - Replacement of Comer Gearbox L-25J 1:1.9

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Max. output torque |

22.7?daNm

|

| Contains oil |

No

|

| Max. oil capacity |

0.35?l

|

| Max. oil change interval |

500?h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Aluminium

|

| Gewicht |

4.1?kg

|

| Gear arrangement Reducing |

1 - 2

|

| Input power kW / HP Increasing |

11 / 15?kW/HP

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

7 / 9.5?kW/HP

|

| Output Torque DaNm Increasing |

9.9?daNm

|

| Ratio Increasing |

1: 1.9

|

| Ratio Reducing |

1.9: 1

|

| Shaft X |

1 3/8" (6) (A)

|

| Shaft Z |

22 (D)

|

Ynlieding

The Flail Mower Gearbox is an essential component of a flail mower, as it transmits power from the tractor to the cutting rotor. Our gearbox is a direct replacement for the Comer Code L25J 1:1.9, providing a reliable and efficient solution for your flail mower needs.

Features

- Durable cast iron housing for long-lasting performance

- High-strength gears for smooth and efficient power transmission

- 1:1.9 gear ratio for optimal cutting speed

- Standard 6-spline input and output shafts for easy installation

- Compatible with a wide range of flail mowers

Spesifikaasjes

Our Flail Mower Gearbox has the following specifications:

- Gear ratio: 1:1.9

- Input shaft: 1-3/8" 6-spline

- Output shaft: 1-3/4" 6-spline

- Housing: Cast iron

- Weight: 33 lbs

Installation

Installing the Flail Mower Gearbox is a straightforward process. First, remove the old gearbox from your flail mower. Then, attach the new gearbox to the mounting plate using the provided bolts. Finally, connect the input and output shafts to the tractor and cutting rotor, respectively, using the standard 6-spline couplers. Refer to the instruction manual for more detailed installation steps and torque specifications.

Maintenance

To ensure optimal performance and longevity of the Flail Mower Gearbox, regular maintenance is recommended. This includes checking the oil level and replacing it if necessary, inspecting the gears for wear and damage, and greasing the input and output shafts. Refer to the instruction manual for the recommended maintenance schedule and procedures.

Applikaasjes

Our Flail Mower Gearbox is suitable for a wide range of flail mowers, including agricultural, municipal, and industrial applications. It provides reliable and efficient power transmission for a clean and precise cut, making it an ideal choice for maintaining parks, golf courses, and other outdoor areas.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We take pride in offering top-quality agricultural gearboxes, including the Flail Mower Gearbox - Replacement of Comer Code L25J 1:1.9. Our gearboxes stand out due to their unique selling points, emphasizing product quality, excellent customer service, and showcasing our manufacturing capabilities.

At RP Techniek BV, we not only specialize in agricultural gearboxes but also offer a wide range of other agricultural machinery parts and transmission components. With our extensive selection, you can find everything you need for your farming equipment. Whether it's belts, sprockets, or bearings, we have you covered.

With a commitment to delivering superior products and ensuring customer satisfaction, our team at RP Techniek BV is dedicated to providing the best solutions for your agricultural needs. Trust us to provide durable and reliable gearboxes that will enhance the performance and efficiency of your agricultural machinery.

PTO Shafts for Agricultural Gearboxes

The PTO shaft is an essential component that connects the agricultural gearbox to various machinery, including the flail mower gearbox. Specifically, when it comes to replacing the Comer Code L25J 1:1.9 on the flail mower gearbox, our company offers the appropriate PTO shafts that ensure a seamless connection between the agricultural gearbox and the machinery.

At our company, we understand the importance of reliable and efficient agricultural equipment. That's why we provide high-quality PTO shafts designed specifically for agricultural gearboxes. With our expertise in the field, you can trust that our PTO shafts are durable, dependable, and capable of transferring power effectively.

Our wide selection of PTO shafts is available for sale, catering to various agricultural needs. Whether you require a specific length or a particular design, we have the right PTO shaft to suit your requirements. By choosing our products, you can ensure smooth power transmission and enhanced performance for your agricultural machinery.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...