In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

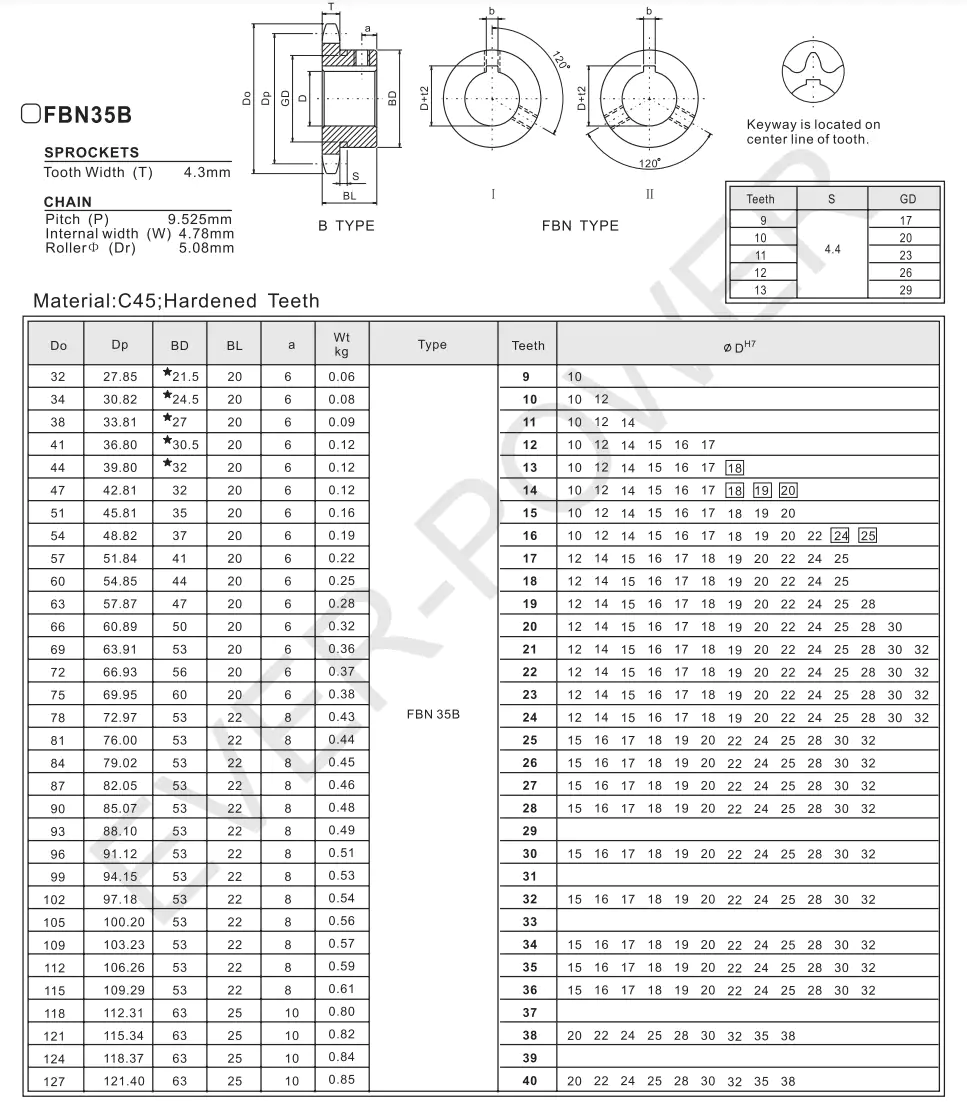

FBN35B Finished Bore Sprocket

The FBN35B Finished Bore Sprocket is engineered for precision and durability, ideal for various industrial applications. Constructed from high-quality materials, it ensures reliable performance and longevity. With a finished bore design, it allows for easy installation and optimal fit with compatible chains, enhancing overall efficiency in machinery operations.

Specifications of FBN35B Finished Bore Sprocket

The FBN35B Finished Bore Sprocket is engineered for precise compatibility with specific shaft sizes, eliminating the need for additional machining processes. It is extensively utilized in power transmission systems, particularly in chain drive setups that facilitate the transfer of power between rotating shafts. This premium sprocket is designed to meet various industrial requirements effectively.

Materials and Manufacturing Process

This finished bore sprocket is constructed from high-quality materials, including high carbon steel, alloy steel, or stainless steel. The manufacturing process involves multiple critical stages, such as material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, surface treatment, and comprehensive quality inspection. Each stage is executed with precision and care to ensure that the final product meets the highest quality standards.

- Material Selection: The materials chosen, whether high carbon steel, alloy steel, or stainless steel, are based on the specific requirements of the application to ensure optimal performance.

- Cutting: Raw materials are shaped into the necessary dimensions using advanced cutting machinery, ensuring accuracy.

- Stamping: The pre-shaped materials are then stamped into the desired sprocket configuration, preparing them for further processing.

- Forging: The sprocket undergoes a forging process to significantly enhance its strength and durability for demanding applications.

- Machining: Precision operations, including turning, milling, and drilling, are performed to achieve exact specifications required for effective functioning.

- Heat Treatment: The sprocket is subjected to heating at a specific temperature followed by rapid cooling, which increases its hardness and overall strength.

- Surface Hardening: The surface undergoes hardening treatments to improve wear resistance and prolong its operational lifespan.

- Oerflak behanneling: Protective surface treatments are applied to guard against rust and corrosion, ensuring longevity.

- Quality Inspection: A thorough inspection of the finished sprocket is conducted to confirm adherence to stringent quality standards.

Applications of FBN35B Finished Bore Sprocket

The FBN35B Finished Bore Sprocket is utilized across various industrial sectors such as heavy machinery, food processing, packaging, chemical and pharmaceutical manufacturing, assembly lines, and logistics. Its versatile design ensures that it can efficiently handle the demands of different operational environments.

- Heavy Machinery and Equipment: The sprocket plays a crucial role in heavy machinery, facilitating effective power transmission between rotating components.

- Food Processing and Packaging: It is an essential component in food processing and packaging systems, contributing to their efficient operation and reliability.

- Chemical and Pharmaceutical Manufacturing: The sprocket ensures dependable power transmission in equipment used within the chemical and pharmaceutical industries.

- Assembly Lines: It is instrumental in assembly lines, facilitating seamless product movement and efficiency.

- Logistics and Warehousing: The FBN35B sprocket enhances operational efficiency in logistics and warehousing machinery.

Maintenance and Troubleshooting

Regular maintenance and inspections are vital for the optimal performance and longevity of the FBN35B Finished Bore Sprocket. Below are several maintenance and troubleshooting tips to consider:

- Daily Inspection: Conduct daily checks for indications of wear, damage, or misalignment to ensure the sprocket remains in good working condition.

- Cleaning: Consistent cleaning is essential to eliminate dirt and contaminants, which could potentially cause damage or impair the efficiency of the sprocket.

- Lubrication: Proper lubrication is critical for smooth operation. Always use the recommended lubricant and apply it regularly to maintain functionality.

- Adjustment and Calibration: It is important to ensure that alignment and calibration are precise to prevent excessive wear and noise during operation.

- Common Problems and Solutions: Issues such as jumping teeth, breakage, excessive wear, noise, and chain slippage may occur, typically necessitating repairs or the replacement of affected components.

Other Types of Sprockets and Chains

In addition to the FBN35B Finished Bore Sprocket, we offer a wide range of other sprocket types, including taper lock sprockets, QD sprockets, idler sprockets, and various chain models. Our products are tailored to meet diverse industrial requirements while complying with the highest quality standards.

Sprockets Supplier in the Netherlands

RP Techniek BV serves as a prominent supplier in the Netherlands, representing Ever-power Group, a leading manufacturer in the industry. We are committed to providing high-quality products and exceptional service to our clients throughout the Netherlands.

Among our notable offerings is the FBN35B Finished Bore Sprocket, designed for durability and efficiency, ensuring outstanding performance in a multitude of applications. Our products meet rigorous standards, positioning them as reliable choices for machinery needs.

In addition to standard sprockets, our company specializes in custom solutions. We invite customers to share their specific requirements, whether through detailed drawings or samples, allowing us to create non-standard sprockets tailored to meet exact specifications.

Oanfoljende ynformaasje

| Edited | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...