In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Spesifikaasjes

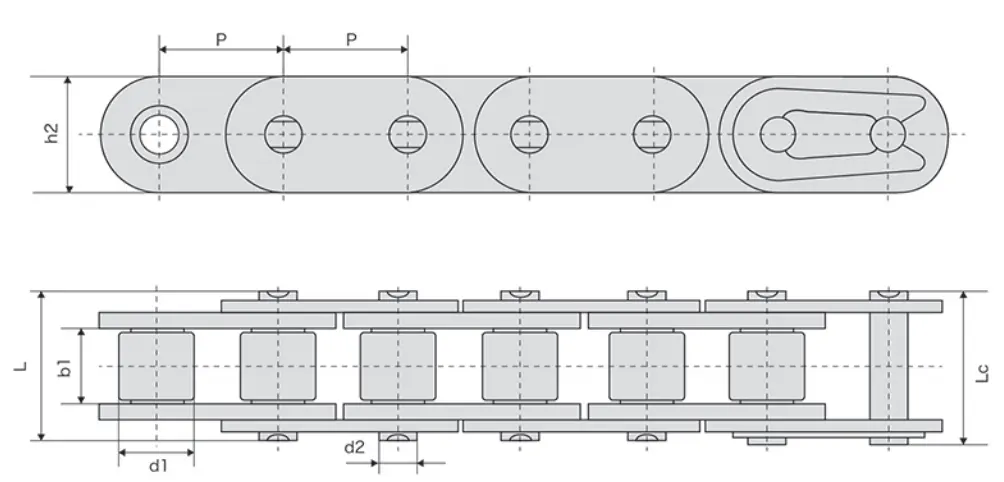

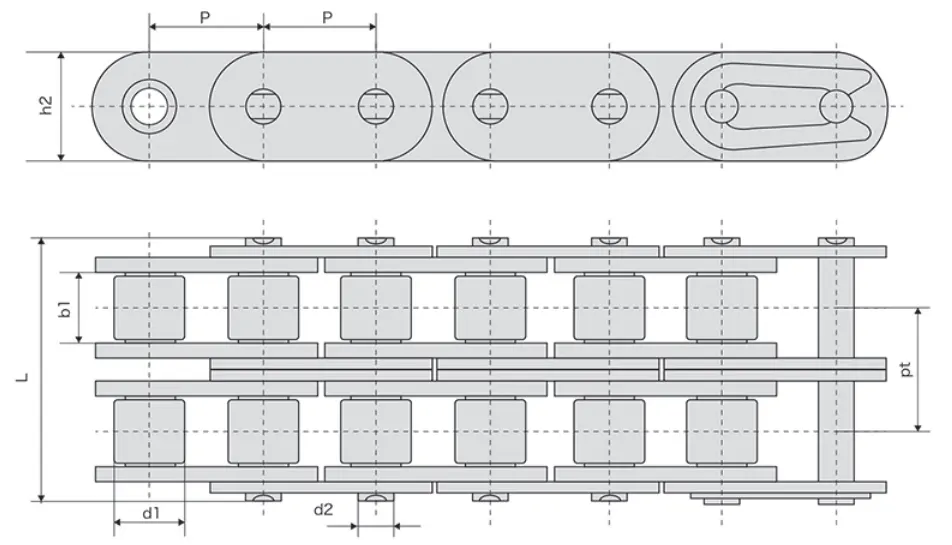

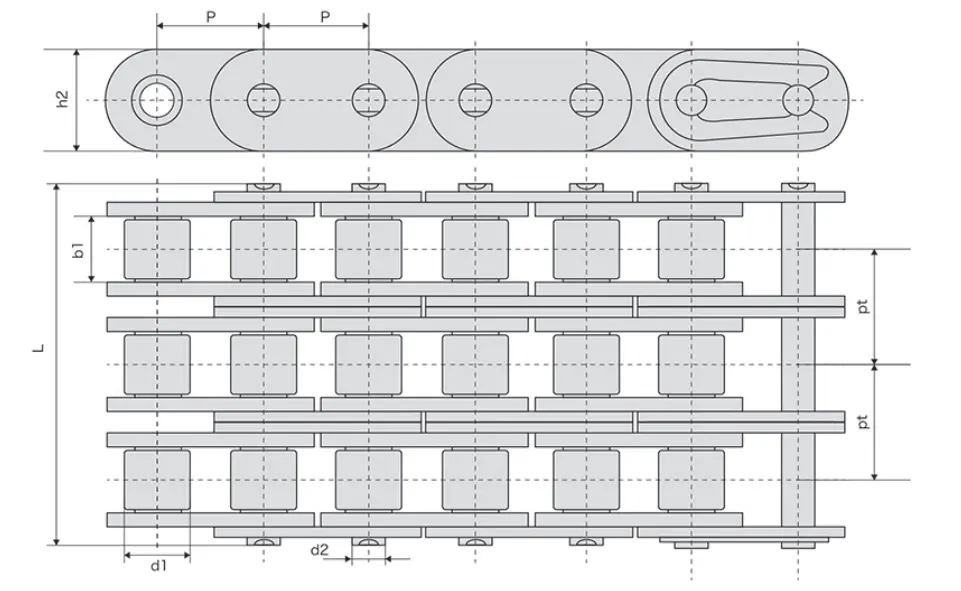

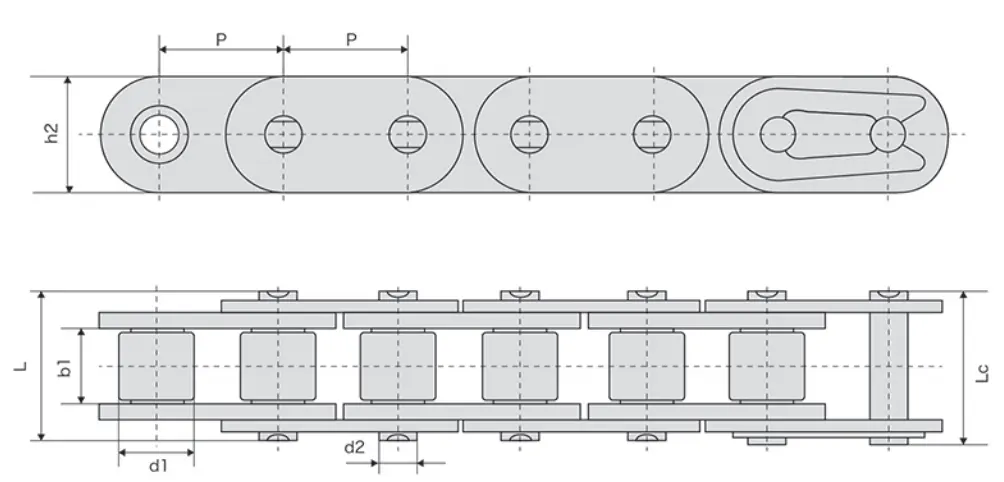

- Product: C16BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates

- Material: Duplex stainless steel

- Type: Roller chain

- Plate type: Straight side plates

The C16BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality roller chain made from duplex stainless steel. This chain is specifically designed for applications that require durability and resistance to corrosion.

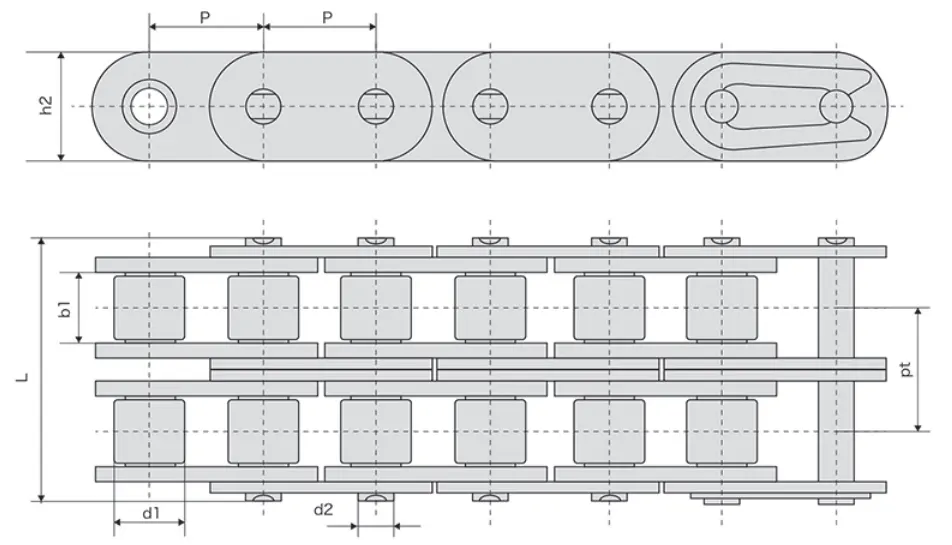

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

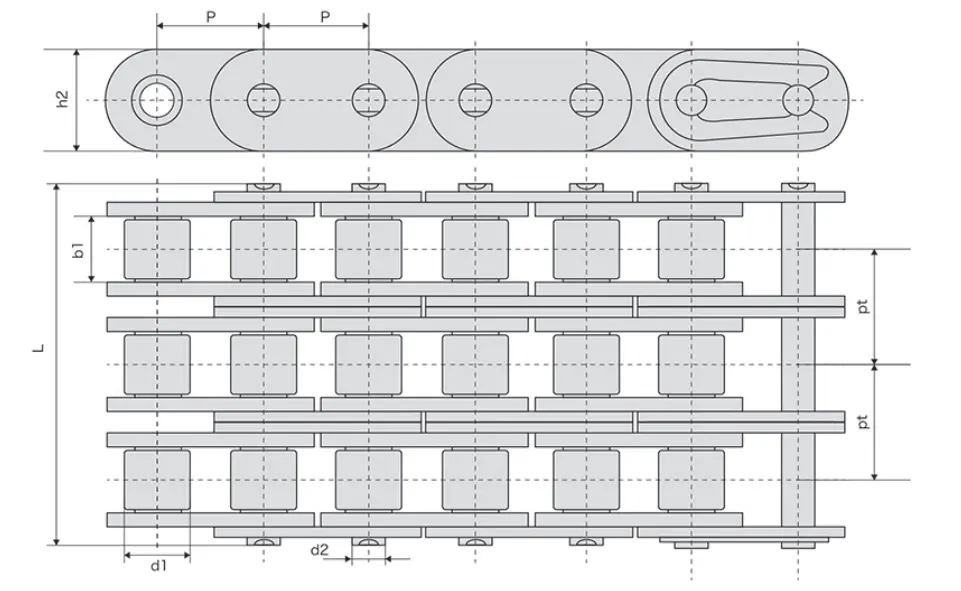

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Title 1: Introduction to C16BSS-2 Duplex Stainless Steel Roller Chain

Duplex Stainless Steel Roller Chain with Straight Side Plates, also known as C16BSS-2, is a high-quality roller chain designed for applications requiring strong, durable, and corrosion-resistant chain performance. With its innovative design and advanced materials, the C16BSS-2 roller chain offers exceptional reliability and longevity in challenging environments.

Title 2: Features and Benefits

Superior Corrosion Resistance

The C16BSS-2 roller chain is constructed using duplex stainless steel, a material known for its excellent corrosion resistance properties. This ensures the chain can withstand harsh conditions, such as exposure to chemicals, moisture, and high temperatures, without compromising its performance.

High Strength and Durability

Thanks to its robust construction, the C16BSS-2 roller chain offers exceptional strength and durability. It can handle heavy loads and withstand repetitive stress, making it suitable for demanding applications where reliable performance is crucial.

Smooth and Quiet Operation

The C16BSS-2 roller chain is designed to provide smooth and quiet operation, minimizing noise and vibration. This feature is particularly desirable in applications where noise reduction is essential, such as conveyor systems or machinery in noise-sensitive environments.

Wide Temperature Range

With its ability to withstand extreme temperatures, the C16BSS-2 roller chain offers excellent versatility. It can operate reliably in both high and low temperature environments, making it suitable for a wide range of industries and applications.

Easy Maintenance

The C16BSS-2 roller chain requires minimal maintenance, thanks to its durable materials and high-quality construction. This reduces downtime and associated costs, ensuring optimal performance and productivity for your application.

Title 3: Applications

The C16BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is widely used in various industries and applications, including:

- Food and beverage processing

- Chemical and pharmaceutical industries

- Packaging and material handling

- Agricultural machinery

- Water treatment plants

Title 4: Technical Specifications

Here are the technical specifications of the C16BSS-2 Duplex Stainless Steel Roller Chain:

- Chain Type: C16BSS-2

- Material: Duplex stainless steel

- Pitch: 1 inch

- Roller Diameter: 0.625 inch

- Plate Height: 0.885 inch

- Breaking Load: 10,000 lbs

- Operating Temperature: -40¡ãF to 500¡ãF

Title 5: Conclusion

The C16BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a reliable and high-performing roller chain designed for demanding applications. With its superior corrosion resistance, high strength, smooth operation, wide temperature range, and easy maintenance, it offers exceptional value and longevity. Whether you need a roller chain for food processing, chemical industries, or material handling, the C16BSS-2 delivers durability and performance you can trust.

Choose Our Stainless Steel Roller Chains

RP Techniek BV, the Netherlands sales agent of Ever-power Group, proudly presents the C16BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates. This high-quality product showcases our company's unique selling points, emphasizing superior product quality and excellent service. With our strong manufacturing capabilities, we ensure that every stainless steel roller chain meets the highest standards.

In addition to the C16BSS-2, we offer a wide range of other stainless steel roller chains for sale. Our diverse selection caters to various industry needs, providing reliability and durability in any application. Trust in our expertise and let us provide you with the perfect stainless steel roller chain solution.

For a visual representation of our products, please refer to the image below:

Choose RP Techniek BV as your go-to supplier for stainless steel roller chains. Experience the excellence of our products and services today.

Sprockets for Sale

When it comes to finding the perfect match for the C16BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, our company offers a wide range of options. Our collection of sprockets is designed to provide the ideal pairing for this particular chain.

Whether you need a small, compact sprocket for a delicate application or a large, robust one for heavy-duty tasks, we have you covered. Our inventory includes various types of sprockets, including those with different tooth counts, bore sizes, and materials.

Our sprockets are meticulously engineered to ensure precise alignment and smooth operation, enhancing the performance and longevity of your chain system. With our high-quality sprockets, you can expect reliable power transmission and minimal wear and tear.

Take a look at the accompanying image below to get a glimpse of the exceptional sprockets we offer:

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...