In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of 901 Sugar Mill Chain

- Chain Type: 901 Sugar Mill Chain

- Pitch Size: 51mm

- Roller Diameter: 25.4mm

- Width Between Inner Plates: 38.1mm

- Pin Diameter: 15.88mm

- Plate Height: 76.2mm

- Overall Width: 72.39mm

- Average Tensile Strength: 413.6kN

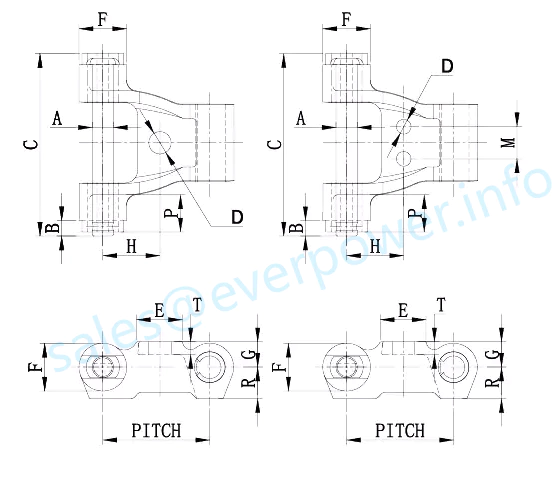

| Chain No. | Pitch | IN | C | D | E | F | G | H | M | P | R | T | Weight (Lbs) |

| E41 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.78 | 1.38 | - | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.88 | 1.38 | - | 1.13 | 0.94 | 0.36 | 12.5 |

| E42 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.78 | 1.58 | - | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.88 | 1.48 | - | 1.13 | 0.94 | 0.36 | 12.5 |

| E43 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.78 | 1.38 | 1.09 | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.88 | 1.38 | 1.09 | 1.13 | 0.94 | 0.36 | 12.5 |

| E44 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.78 | 1.58 | 1.09 | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.88 | 1.48 | 1.09 | 1.13 | 0.94 | 0.36 | 12.5 |

| E51 | |||||||||||||

| 907 | 3.17 | 0.625 | 5.5 | 0.66 | 1.31 | 1.44 | 0.72 | 1.69 | - | 1.13 | 0.94 | 0.36 | 12.1 |

| E41 | |||||||||||||

| 5174 | 2.36 | 0.58 | 5.18 | 0.38 | 1.12 | 1.08 | 0.64 | 1.18 | 1 | 1.13 | 0.74 | 0.36 | 11.7 |

The 901 Sugar Mill Chain is a high-quality product used in the sugar industry for conveying materials efficiently. This chain is specially designed to withstand the harsh conditions of sugar mills and to provide reliable performance throughout its service life. In this article, we will introduce you to the various features and benefits of the 901 Sugar Mill Chain.

Construction of 901 Sugar Mill Chain

The 901 Sugar Mill Chain is made up of high-quality alloy steel that provides superior strength and durability. The pins and bushes are through-hardened to ensure maximum wear resistance. The sidebars are designed to provide maximum strength and withstand the heavy loads encountered in sugar mills. The chain is preloaded during the manufacturing process to minimize elongation during the initial stages of operation.

Types of 901 Sugar Mill Chain

There are various types of 901 Sugar Mill Chains available, including:

- Standard chain

- Heavy-duty chain

- Cottered type chain

- Extended pitch chain

Features of 901 Sugar Mill Chain

The 901 Sugar Mill Chain has various features that make it ideal for use in sugar mills. These include:

- High-quality alloy steel construction

- Through-hardened pins and bushes for maximum wear resistance

- Preloaded to minimize initial elongation

- Designed to withstand heavy loads

- Available in different types for various applications

- Heat-treated for increased strength and durability

Benefits of 901 Sugar Mill Chain

The 901 Sugar Mill Chain provides various benefits, including:

- High performance even in harsh conditions

- Long service life due to its superior strength and wear resistance

- Reduced downtime and maintenance costs

- Increased productivity and efficiency

- Environmentally friendly due to its long service life and recyclability

Applications of 901 Sugar Mill Chain

The 901 Sugar Mill Chain is suitable for various applications in the sugar industry, including:

- Conveying raw materials and finished products

- Conveying bagasse and ash

- Transporting sugar cane within the mill

- Operating centrifugal machines and sugar dryers

Konklúzje

The 901 Sugar Mill Chain is a reliable and efficient product for use in the sugar industry. Its superior strength and wear resistance make it ideal for conveying materials and operating machinery in harsh conditions. The various types of chains available and the benefits they provide make the 901 Sugar Mill Chain a versatile and cost-effective solution for sugar mills. Ever-Power Industry is a trusted manufacturer of the 901 Sugar Mill Chain and can provide customized solutions to meet the specific needs of your sugar mill.

Choose Our Malleable Casting Chains

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands. We specialize in providing high-quality malleable cast iron chains, with our 901 Sugar Mill Chain being a standout product. Our malleable casting chains offer unique selling points that emphasize superior product quality, exceptional service, and our strong manufacturing capabilities.

In addition to our malleable casting chains, we also offer a wide range of other types of casting chains. These chains are designed to meet various industry needs and are manufactured to the same high standards as our malleable cast iron chains. With our diverse product portfolio, we ensure that our customers can find the perfect casting chain solution for their specific requirements.

Sprockets for Sale

When it comes to finding the right chain sprocket to go with the 901 Sugar Mill Chain, our company has you covered. We offer a wide variety of chain sprockets that are suitable for use with this chain, ensuring that you can find the right fit for your needs.

Our chain sprockets are available in a range of sizes, from small to large, and in a variety of materials, including steel and aluminum. This means that you can find the perfect sprocket for your application, no matter what your specific requirements may be.

In addition to our selection of chain sprockets, we also offer competitive pricing and timely delivery, ensuring that you can get the parts you need when you need them. So if you're in the market for a new chain sprocket for your 901 Sugar Mill Chain, look no further than our company.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...