In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Types and Sizes of 40 Weld on Sprockets and Hubs

| No.Teeth | 40 |

| 1/2" Pitch | |

| 12 | 40V12 |

| 13 | 40V13 |

| 14 | 40V14 |

| 15 | 40V15 |

| 16 | 40W16 |

| 17 | 40W17 |

| 18 | 40W18 |

| 19 | 40W19 |

| 20 | 40X20 |

| 21 | 40X21 |

| 22 | 40X22 |

| 23 | 40X23 |

| 24 | 40X24 |

| 25 | 40X25 |

| 26 | 40X26 |

| 27 | 40X27 |

| 28 | 40X28 |

| 29 | 40X29 |

| 30 | 40X30 |

| 31 | 40X31 |

| 32 | 40X32 |

| 33 | 40X33 |

| 34 | 40X34 |

| 35 | 40X35 |

| 36 | 40X36 |

| 37 | 40X37 |

| 38 | 40X38 |

| 39 | 40X39 |

| 40 | 40X40 |

| 42 | 40X42 |

| 43 | 40X43 |

| 44 | 40X44 |

| 45 | 40X45 |

| 48 | 40X48 |

| 50 | 40X50 |

| 54 | 40X54 |

| 60 | 40X60 |

| 70 | 40X70 |

| 72 | 40X72 |

| 80 | 40X80 |

| 84 | 40XB4 |

| 90 | 40X90 |

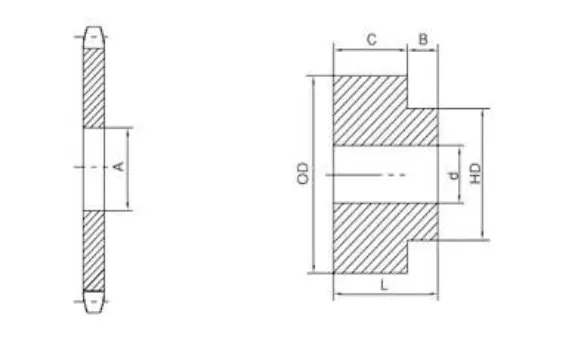

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | IN |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | 1-1/8 |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | 1-5/8 |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | 2 |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | 2 |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | 2-3/4 |

Applications of 40 Weld on Sprockets and Hubs

The 40 Weld on Sprockets and Hubs are ideal for applications in manufacturing, agriculture, and automotive industries. They are commonly used in conveyor systems, agricultural machinery, and custom-built equipment where durability and precision are essential. These components facilitate efficient power transmission, making them suitable for projects requiring robust performance and reliability.

Installation of 40 Weld on Sprockets and Hubs

To install the 40 Weld on Sprockets and Hubs, follow these steps:

- Ensure that the surface of the hub is clean and free from rust or debris.

- Align the sprocket onto the hub, ensuring proper fit and alignment with the chain.

- Use a suitable welding technique, such as MIG or TIG, to securely weld the sprocket to the hub.

- Allow the weld to cool completely before testing the installation.

- Check for proper alignment and functioning before putting it into operation.

How to Choose the Right Weld on Sprockets and Hubs

When selecting the appropriate weld on sprockets and hubs, consider the following steps:

- Identify Your Needs: Determine the specific application and load requirements.

- Check Compatibility: Ensure the sprocket size and hub design fit your existing machinery.

- Material Selection: Choose durable materials that can withstand operational stresses.

- Consult Specifications: Review product specifications to match pitch, tooth count, and other dimensions.

Weld on Sprockets and Hubs for Sale in Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are one of the top suppliers of sprockets in the country. Our extensive range includes 40 different types of weld on sprockets and hubs designed to meet various industrial needs. Each product is crafted with precision to ensure durability and efficiency in performance.

At RP Techniek BV, we pride ourselves on offering exceptional service to our clients. Our team is dedicated to providing expert advice and support, ensuring that you find the right products for your applications. We are committed to delivering quality and reliability with every transaction, making us a trusted partner in your business success.

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...