In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

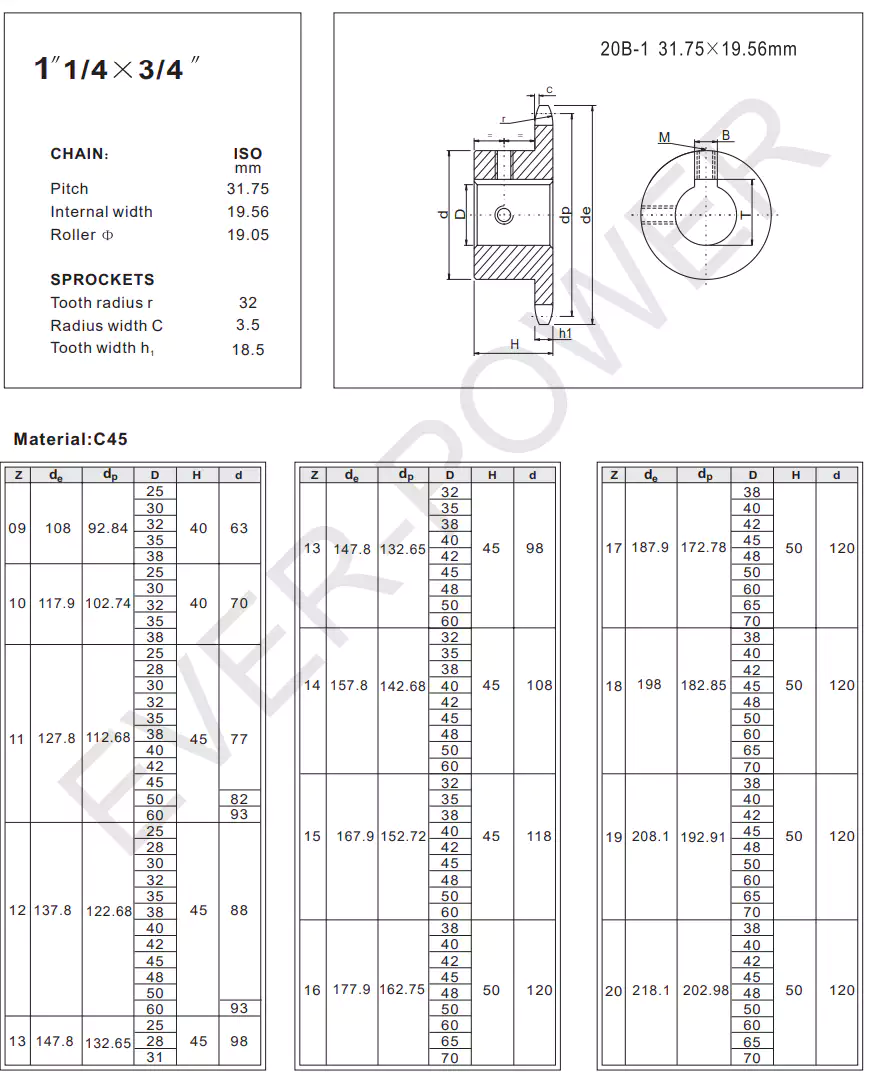

20B-1 Finished Bore Sprocket

The 20B-1 Finished Bore Sprocket is designed for high-performance applications, featuring precision engineering for optimal durability and efficiency. Its finished bore allows for easy installation on various shafts, ensuring a secure fit. Ideal for industrial machinery and conveyor systems, this sprocket guarantees reliable operation and minimal maintenance, enhancing overall productivity.

Specifications of 20B-1 European Standard Finished Bore Sprocket

Overview of Finished Bore Sprocket

A finished bore sprocket is defined by its pre-machined hole, which allows for straightforward installation onto a shaft without requiring additional machining. The 20B-1 European standard sprocket is extensively utilized in various industries such as heavy machinery, food processing, and assembly lines, making it a versatile component in mechanical systems.

Materials and Manufacturing Process

The construction of the 20B-1 European standard finished bore sprocket typically involves high-carbon steel, alloy steel, or stainless steel. The manufacturing process includes multiple critical stages: selecting materials, cutting to size, punching holes, forging components, machining for precision, heat treating for strength, surface hardening for durability, surface treatment for corrosion resistance, quality inspection to ensure reliability, and finally, packaging the product. Each stage is essential for achieving the sprocket’s high durability, dependability, and overall quality.

Applications of Sprocket

Sprockets are prevalent in heavy machinery and equipment, as well as in food processing and packaging industries, chemical and pharmaceutical sectors, assembly lines, and logistics and warehousing environments. Their robust design and reliable performance make them well-suited for use in demanding conditions, ensuring smooth operation and longevity in various applications.

Maintenance and Common Problems

To ensure optimal performance and extend the lifespan of sprockets, it is crucial to perform regular inspections, cleaning, lubrication, adjustments, and calibrations. Common issues such as tooth jumping, breakage, wear, excessive noise, and chain slippage can occur due to improper installation, inadequate lubrication, or worn components. Timely identification and resolution of these problems are essential to prevent further damage to both the sprocket and the machinery with which it operates.

Other Types of Sprocket and Chain

We also provide a diverse range of other sprocket types including taper lock sprockets, QD sprockets, and idler sprockets, along with various models of chains. Our products are engineered and manufactured to adhere to international standards, ensuring that they meet customer expectations while delivering optimal performance and reliability across multiple applications.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, offering high-quality sprockets and related products tailored to meet a wide array of industrial requirements. Our signature product, the 20B-1 European Standard Finished Bore Sprocket, is designed for durability and precision, ensuring excellent performance in numerous applications. We are committed to providing exceptional products and services to our customers.

In addition to standard sprockets, we offer customization options tailored to specific customer needs. Clients are encouraged to submit drawings or samples for non-standard sprocket designs, allowing us to develop customized solutions that address unique operational challenges effectively.

Oanfoljende ynformaasje

| Edited | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...