In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

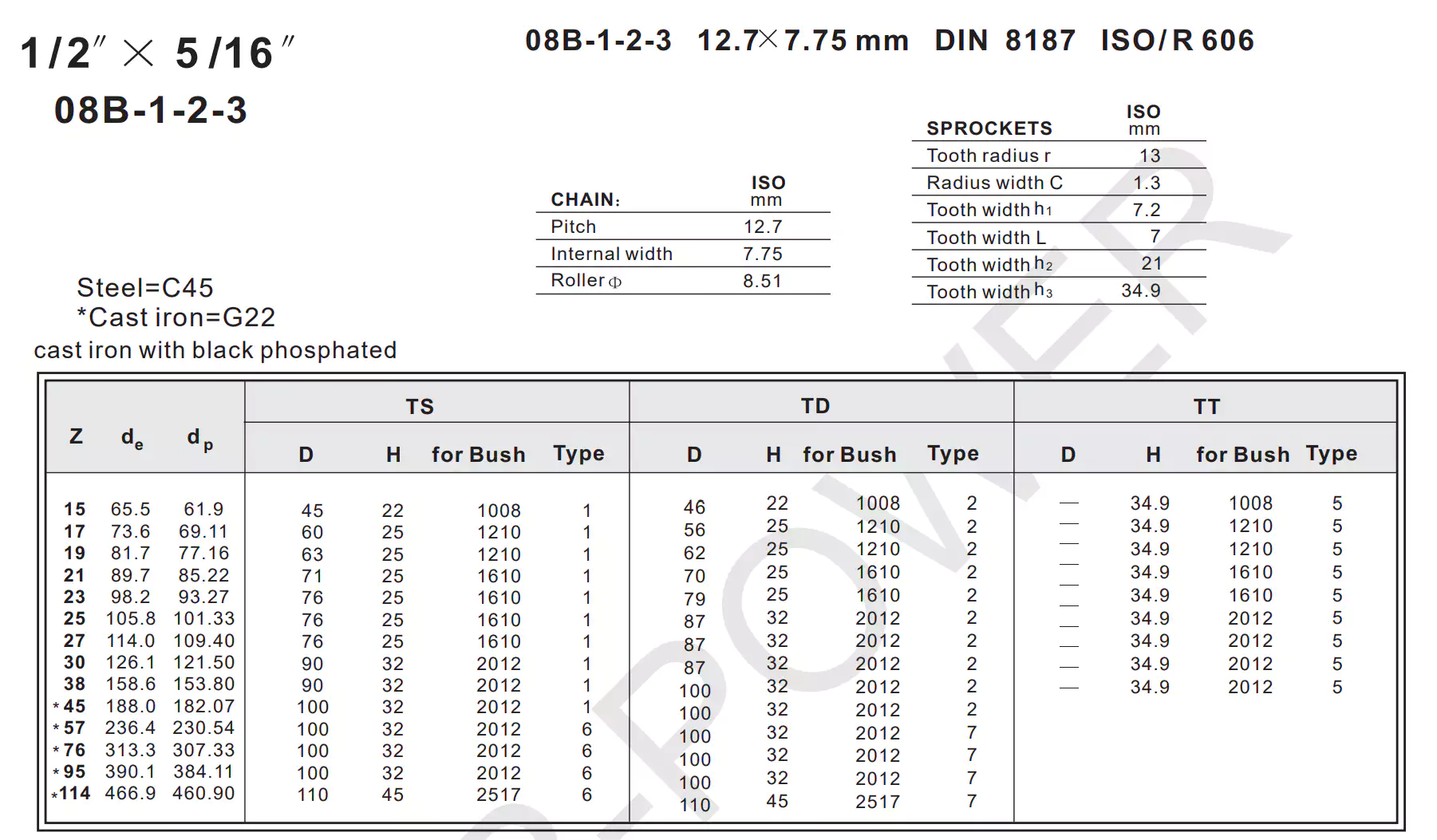

08B-1-2-3 1/2″ Taper Lock Sprocket

The 08B-1-2-3 1/2″ Taper Lock Sprocket is designed for reliable performance in various machinery applications. Featuring a robust taper lock design, it ensures easy installation and secure fastening. Its durable construction guarantees long-lasting use, making it an essential component for efficient power transmission in industrial settings.

08B-1-2-3 1/2" Taper Lock Sprocket Specifications

The Taper Lock Sprocket 08B-1-2-3 European Standard represents a vital component in power transmission systems. Engineered with a taper lock mechanism, this sprocket allows for straightforward installation and removal, making it a popular choice across various industries. Its robust design ensures versatility and reliability, catering to a wide range of operational demands.

Definition and Basic Structure

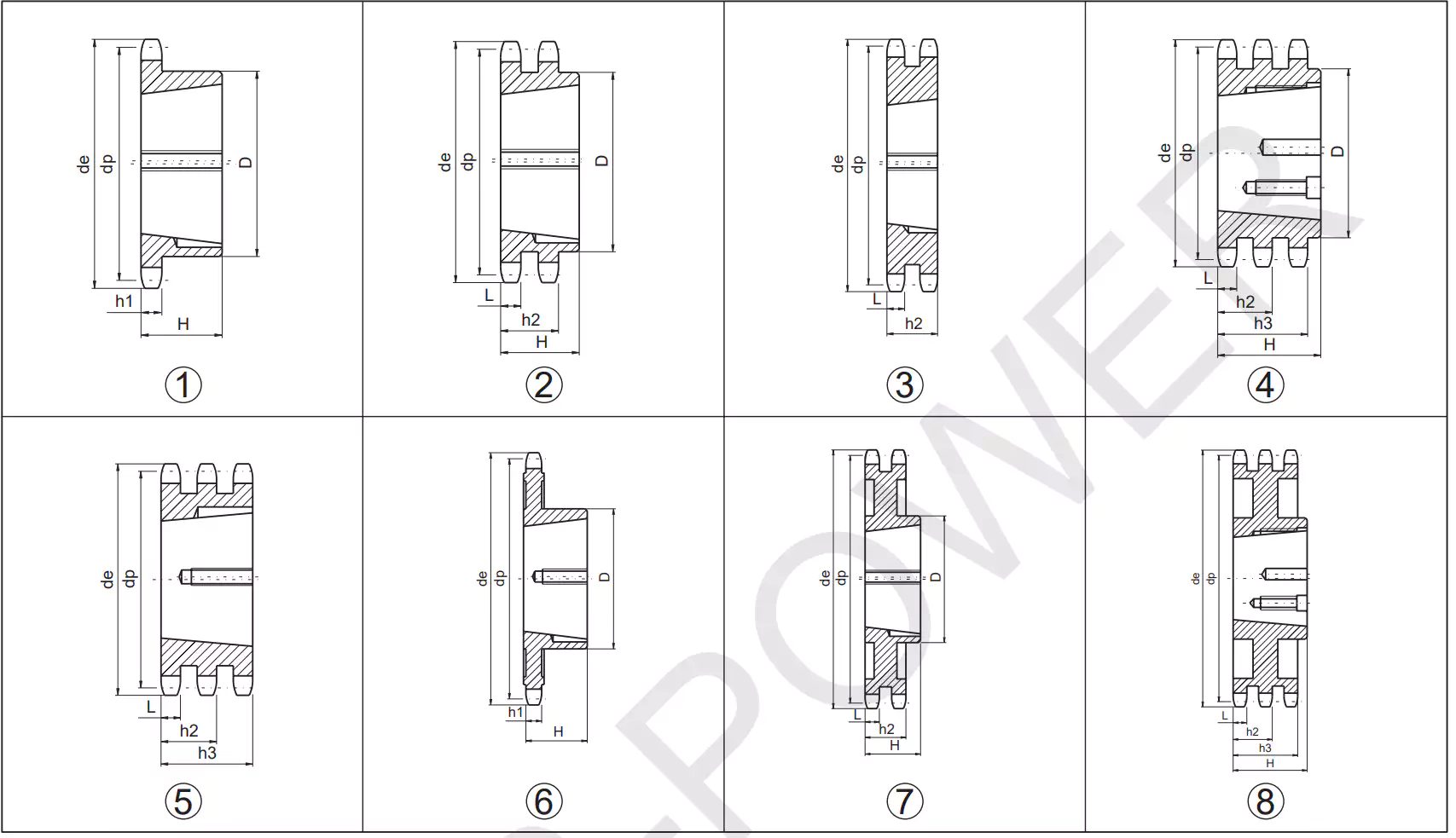

The taper lock sprocket functions as a crucial element in power transmission systems, typically categorized as a type of chain wheel. This component consists of a sprocket equipped with teeth and a taper lock bushing. The teeth engage seamlessly with chain links, facilitating the transfer of rotary motion and power, which is essential for machinery operation in various fields.

Features and Benefits

- Easy Installation: Featuring a taper lock bushing, the sprocket allows for quick and hassle-free installation, eliminating the need for specialized tools.

- Precise Positioning: The design incorporates a taper lock mechanism that guarantees accurate alignment, significantly reducing the likelihood of misalignment and enhancing overall performance.

- Wide Applicability: This sprocket is adaptable to numerous power transmission scenarios, making it an excellent choice for diverse industrial applications.

- Reliability: The taper lock mechanism creates a secure and dependable connection between the sprocket and the shaft, substantially lowering the risk of slippage or mechanical failure.

- Low Maintenance Cost: The design minimizes maintenance requirements, leading to notable cost savings throughout the operational lifetime of the system.

Installation and Removal Process

- Prepare Tools and Materials: Collect all necessary tools and materials needed for the installation, including the taper lock bushing, sprocket, locknut, and the appropriate wrenches.

- Clean Shaft and Sprocket Surface: It is crucial to ensure that both the shaft and sprocket surfaces are thoroughly cleaned and free of debris, which is essential for achieving a proper fit and secure connection.

- Place Taper Lock Bushing: Slide the taper lock bushing onto the shaft, ensuring it fits snugly to avoid any movement during operation.

- Install Sprocket: Position the sprocket over the taper lock bushing, aligning its teeth meticulously with the chain links to ensure proper engagement.

- Tighten Locknut: Use a wrench to securely tighten the locknut, confirming that the sprocket is firmly attached to the shaft to prevent dislodgment during use.

Manufacturing Process

- Raw Material Preparation: Acquire the necessary materials which are essential for the manufacturing process of the sprocket.

- Cutting: Proceed to cut the raw material into the required shape and size to prepare it for further processing.

- Forging or Casting: Employ either forging or casting techniques to create the basic shape of the sprocket from the raw material.

- Machining: Utilize advanced machining processes to refine the sprocket, ensuring that it meets precise dimensions and has smooth surfaces.

- Gear Cutting: Cut the teeth on the sprocket using specialized gear cutting tools to ensure they meet the necessary specifications.

- Heat Treatment: Implement heat treatment procedures to enhance both the hardness and strength of the sprocket, improving its durability.

- Surface Treatment: Apply surface treatments, such as coating or plating, to increase corrosion resistance while enhancing the aesthetics of the sprocket.

- Quality Inspection: Conduct thorough inspections to ensure that each sprocket adheres to the required quality standards and specifications.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, focusing on delivering high-quality sprockets and other power transmission products. Our highlighted product, the 08B-1-2-3 1/2" Taper Bore Sprocket, showcases our dedication to precision engineering and durability. This sprocket is specifically designed to ensure optimal performance in a variety of industrial applications, facilitating efficient power transfer and enhancing operational reliability.

Alongside our standard selection of sprockets, we take pride in offering customized solutions tailored to meet specific client needs. We encourage customers to present their designs and samples for bespoke manufacturing, ensuring we can cater to the unique requirements of every client.

Oanfoljende ynformaasje

| Edited | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...