Ynlieding

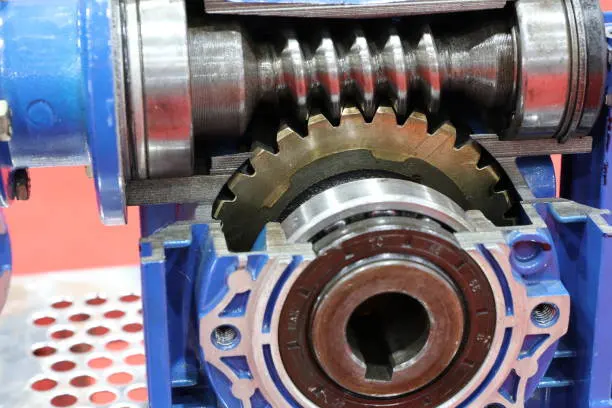

Worm gearboxes are essential components in various industries, providing efficient power transmission and torque conversion. In this article, we will explore the recommended operating temperatures for EPRV Series small worm gearboxes and delve into their significance in different applications.

1. Understanding Operating Temperatures

Operating temperatures play a critical role in the performance and longevity of small worm gearboxes. It is crucial to maintain a suitable temperature range to avoid overheating or excessive wear and tear.

1.1 Ideal Temperature Range

The ideal operating temperature range for EPRV Series small worm gearboxes is between 20¡ãC and 80¡ãC. Operating within this range ensures optimal efficiency and minimal degradation of lubricants and materials, maximizing the gearbox's lifespan.

1.2 Effects of Low Temperatures

Operating below the recommended temperature range can lead to increased friction and decreased lubrication effectiveness. This can result in gear wear and potential damage to the gearbox components.

1.3 Effects of High Temperatures

Operating above the recommended temperature range can cause lubricants to break down, leading to insufficient lubrication and potential gearbox failure. It can also accelerate wear on gear teeth, bearings, and seals.

2. Factors Affecting Operating Temperatures

Several factors influence the operating temperatures of EPRV Series small worm gearboxes. Understanding these factors can help optimize their performance and prevent any adverse effects.

2.1 Load and Torque

The applied load and torque have a direct impact on the operating temperature of worm gearboxes. Higher loads and torques result in increased friction, generating more heat and potentially raising the gearbox temperature.

2.2 Speed of Rotation

The speed of rotation affects the operating temperature as higher rotational speeds generate more heat due to increased friction between the worm and gear. It is essential to consider the gearbox's maximum recommended speed to prevent overheating.

2.3 Ambient Environment

The ambient temperature and surrounding conditions can influence the gearbox's operating temperature. Extreme temperatures, humidity, and contaminants in the environment may require additional cooling or protective measures.

3. Importance of Operating Temperatures

Maintaining the recommended operating temperatures for EPRV Series small worm gearboxes is crucial for ensuring their reliable performance and longevity. This section explores the reasons why temperature control is essential.

3.1 Optimal Efficiency

Operating within the recommended temperature range allows the gearbox to achieve optimal efficiency, minimizing energy loss and maximizing power transmission capabilities.

3.2 Lubrication Effectiveness

Proper temperature control ensures that lubricants maintain their viscosity and lubrication properties, reducing friction and wear between moving components.

3.3 Component Longevity

By operating at the recommended temperature range, the worm gearboxes' components, such as gears, bearings, and seals, experience less stress and wear, resulting in extended lifespan and reduced maintenance costs.

4. Electric motors for Sale

The integration of small worm gearboxes with electric motors is essential for many industrial applications. The synergy between these two components ensures efficient power transmission and system performance.

At Ever-power Group, we offer a wide range of electric motors that complement our EPRV Series small worm gearboxes. Our electric motors are designed to meet the highest industry standards, providing optimal power and reliability.

4.1 The Complementary Relationship

Small worm gearboxes and electric motors work hand in hand to deliver precise and controlled rotational motion. The gearbox enhances the motor's torque and speed capabilities, while the motor provides the necessary power to drive the gearbox.

4.2 Importance of Compatibility

Ensuring compatibility between the gearbox and electric motor is crucial for achieving seamless integration. Proper selection and matching of these components guarantee optimal system performance and efficiency.

4.3 Our Offerings

At Ever-power Group, we provide a comprehensive range of electric motors that are suitable for various industrial applications. Our motors are designed with advanced technologies and built to withstand demanding conditions, ensuring reliable and efficient operation.

4.4 Contact Us

If you are interested in exploring our EPRV Series small worm gearboxes and electric motors for your applications, please don't hesitate to contact us. Our team of experts will assist you in selecting the right products and provide any necessary support.

Oer Us

RP Techniek BV is the Netherlands sales agent of Ever-power Group, a renowned transmission equipment manufacturer. With over 25 years of experience, we specialize in the design, production, and sales of speed reducers, including worm gearboxes.

Our production facilities are equipped with advanced manufacturing and testing equipment, enabling us to deliver high-quality products to customers in Europe, America, Africa, Asia, and beyond. We take pride in offering the best service, top-notch product quality, and competitive prices.

Bewurke troch: Zqq.