The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Robotic Arms

The worm gear in robotic arms is a crucial component that facilitates precise motion control. In robotic systems, this gear mechanism allows for smooth and accurate positioning, making it essential for various applications. The robotic arm worm gear uses include enhancing torque transmission and reducing backlash, which are vital for worm gear for precision robotic motion. Additionally, the worm gear in automated robotic arms ensures reliability and efficiency in operation, making it a preferred choice for engineers seeking high-precision worm gear for robotics.

Specifications of Worm Gear in Robotic Arms

| Spesifikaasje | Details |

|---|---|

| Gear Ratio | 10:1 |

| Materiaal | Aluminum Alloy |

| Load Capacity | 500 N |

| Effisjinsje | 85% |

| Operating Temperature | -20°C to 100°C |

| Gewicht | 1.5 kg |

Why Worm Gears are Suitable for Worm Gear in Robotic Arms

- Worm gears in robotic arms provide high torque and low speed, essential for precise movements.

- They minimize backlash, ensuring accurate positioning, making worm gear for precision robotic motion ideal.

- Worm gear in robotic systems facilitates smooth operation in compact designs, perfect for automated robotic arms.

- High-precision worm gear for robotics contributes to the overall efficiency and effectiveness of robotic arm worm gear uses.

How Worm Gears Work in Robotic Arms

Worm gears are essential components in robotic arms, enabling precise control and movement. In robotic systems, the worm gear provides a compact solution for transferring motion, allowing for high-precision robotic motion. The design of the worm gear in robotic arms offers a significant gear reduction, which translates to increased torque and controlled movement. This makes the worm gear ideal for applications requiring accuracy, such as automated robotic arms. The use of a worm gear for precision robotic motion ensures that adjustments can be made smoothly, enhancing the robot's overall functionality. Many robotic arm worm gear uses are evident in industrial automation, where reliability and precision are paramount.

Manufacturing Process of Worm Gear in Robotic Arms

- Material Selection: The first step in manufacturing worm gears for robotic arms involves selecting high-quality materials that ensure durability and precision. Common choices include alloys with high tensile strength, which are crucial for maintaining the integrity of the worm gear in robotic systems. The right material is vital for the performance of the worm gear in automated robotic arms, as it influences not only the strength but also the wear resistance and overall longevity of the component.

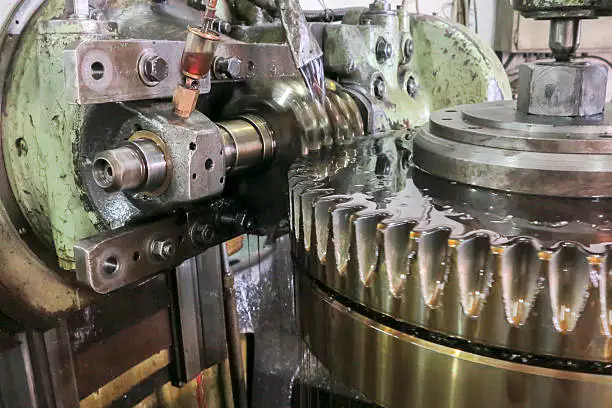

- CNC Machining: After material selection, the manufacturing process typically involves CNC (Computer Numerical Control) machining. This technique allows for the precise cutting and shaping of the worm gear, ensuring that it meets the exact specifications required for robotic arm worm gear uses. CNC machining provides the necessary accuracy for creating the complex geometries found in high-precision worm gear for robotics, enabling smooth and efficient operation within the robotic system.

- Heat Treatment: Following machining, the worm gears undergo heat treatment processes to enhance their mechanical properties. This step is crucial for ensuring that the worm gear in robotic arms has the hardness and strength needed to withstand high loads and stress in automated environments. Heat treatment not only increases durability but also helps in minimizing wear and tear, which is essential for maintaining precision in robotic motion.

- Quality Control: The final stage of the manufacturing process involves rigorous quality control measures. Each worm gear for precision robotic motion is thoroughly inspected for dimensional accuracy and performance. This includes testing for smooth rotation and load-bearing capacity, which are critical factors in the functionality of robotic arms. Ensuring high standards during quality control guarantees that the worm gear in robotic systems operates efficiently and reliably over time.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for the Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our reputation is built on the high quality and superior performance of our products, making us a trusted partner in various industries.

Our offerings include:

- High-Quality Products: We ensure our worm gears meet stringent quality standards, providing reliability and durability in robotic applications.

- Exceptional Craftsmanship: Each product is crafted with precision, ensuring optimal performance in robotic arms.

- Strong Capabilities: Our experienced team is dedicated to meeting customer needs with tailored solutions.

- Comprehensive Support: We offer excellent customer service, ensuring prompt assistance and guidance for all our clients.

Oanfoljende ynformaasje

| Edited | Zqq |

|---|

Blogs Updated

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...