In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

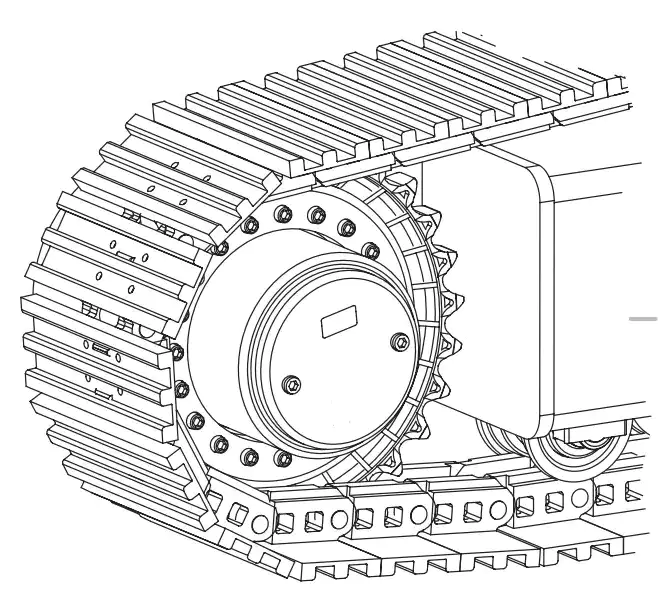

Track Drive for Crawler Tractors

The Track Drive Planetary Gearbox for Crawler Tractors is designed for high efficiency and durability. Its compact structure allows for optimal torque transmission and improved load handling. This gearbox is specifically tailored for crawler tractors, enabling precise movement and enhanced traction on uneven terrain, making it ideal for construction and agricultural applications.

Specifications of Track Drive Planetary Gearbox for Crawler Tractors

| Feature | Description |

|---|---|

| Output Torque Range | 1000-450000 N¡¤m |

| Gear Ratios | i = 5.3 - 500 |

| Support | The gearbox has rotating housing flanges to fit tracks |

| Applicable Motors | Axial piston hydraulic motors, hydraulic orbit motors, or others |

| Hydraulic Motor Options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake |

| High Torque and Load Capacities | Designed to carry equipment over the roughest and steepest terrain |

| Motor Mounting | Designed to allow mounting of plug-in motors |

| Compact Design | Integral multi-disc parking brakes, while still keeping the drive compact |

| Materiaal | Steel structure |

| Easy Maintenance | Filling and draining openings are reasonably located for easy reach |

| Front Mechanical Seal | Designed specifically for earth-moving machines |

| Compatibility | Technical data and installation dimensions of EP400T Series gearbox are the same as those of Rexroth GFT¡T Series and Bonfiglioli 700C Series, allowing interchangeability |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m.) |

| EP400T1 | 1300 | 6.09 | 1000 | 130 |

| EP401T1 | 2000 | 6.2 | 1000 | 270 |

| EP402T2 | 5000 | 12.4-37.1 | 3500 | - |

| EP403T2 | 7000 | 15.4-40 | 3500 | 270 |

| EP405T | 10000 | 20-80 | 3500 | 270 |

| EP405.4T | 11000 | 26-57 | 3500 | 280 |

| EP406AT | 17000 | 23-220 | 3500 | 430 |

| EP406T | 18000 | 28-140 | 3500 | 430 |

| EP406BT3 | 24000 | 63-136 | 3500 | 430 |

| EP407AT | 26000 | 38-136 | 3500 | 430-530 |

| EP407T3 | 36000 | 63-136 | 3500 | 530 |

| EP410T3 | 50000 | 62-177 | 3500 | 530 |

| EP413T3 | 60000 | 86-172 | 3500 | 610 |

| EP414T3 | 80000 | 76-186 | 3500 | 1200 |

| EP415T3 | 110000 | 81-215 | 3000 | 1200 |

| EP416T3 | 160000 | 87-255 | 3000 | 2000 |

| EP417T3 | 220000 | 123-365 | 3000 | 2000 |

| EP418T3 | 270000 | 166-364 | 3000 | 2000 |

| EP419T3 | 330000 | 161-306 | 2500 | 3000 |

| EP420T4 | 450000 | 296-421 | 2500 | 1700 |

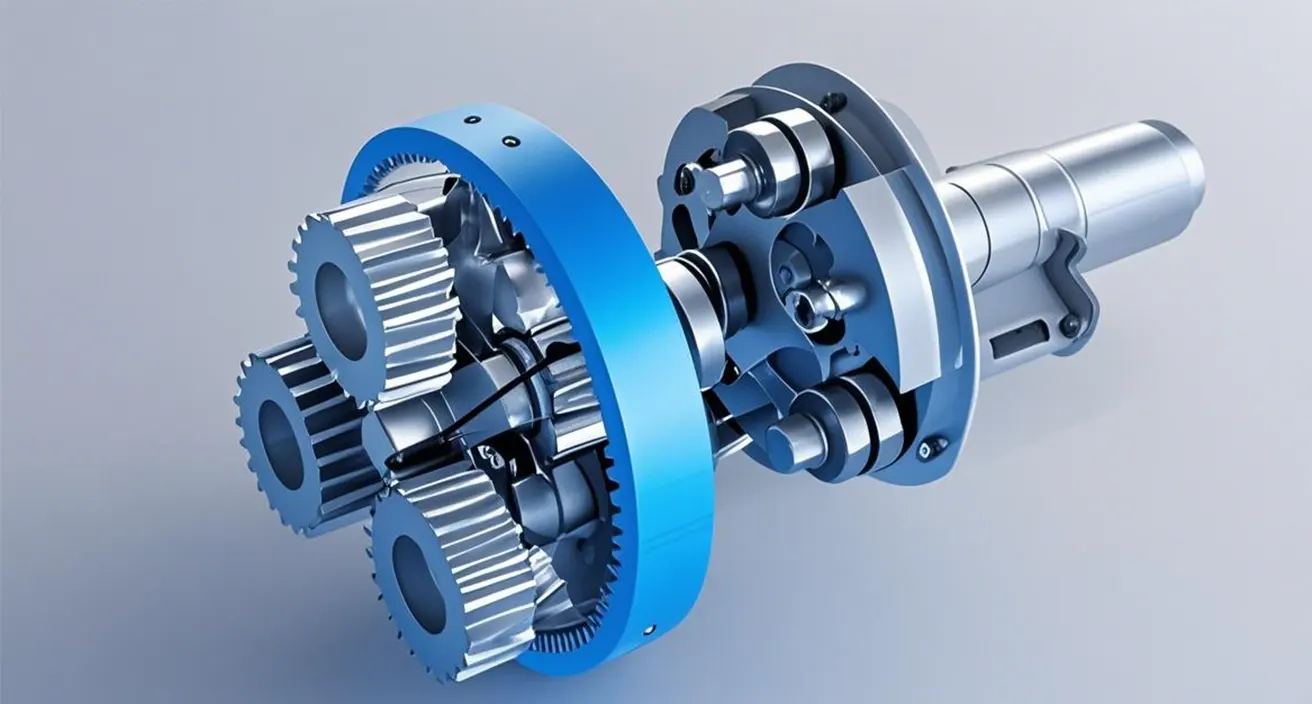

Working Principle of Track Drive Planetary Gearbox for Crawler Tractors

The planetary gear system in a track drive gearbox operates through a central sun gear, surrounded by planet gears that rotate within a ring gear. This design allows for efficient force distribution and compact size. When the input shaft rotates the sun gear, the planet gears engage with both the sun and ring gears, resulting in a reduction of speed while increasing torque. This mechanism is essential for providing the necessary power to crawl through challenging terrains.

Significance of Space Efficiency in Crawler Vehicles

Space efficiency is crucial for crawler vehicles, especially in tight working environments. The Track Drive Planetary Gearbox offers a compact design that allows for a more streamlined integration into the vehicle's structure, optimizing space without compromising performance. Unlike traditional gearboxes, which can be bulky and require more room for installation, the planetary design of the Track Drive Gearbox reduces overall dimensions while enhancing torque output. This reduction in size not only leads to a lighter vehicle but also improves maneuverability and accessibility in confined spaces, making it ideal for construction and agricultural applications.

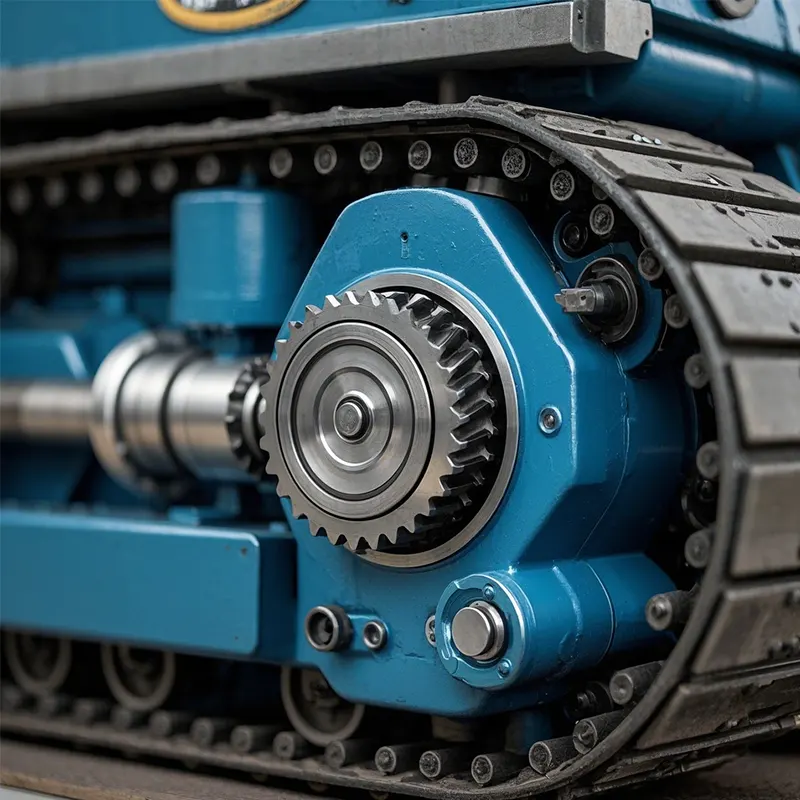

Importance of High Torque in Crawler Vehicles

Crawler vehicles, such as tractors, require high torque to effectively navigate rugged terrain and heavy loads. High torque ensures optimal traction and stability, enabling these machines to operate efficiently in challenging conditions. Additionally, multi-tooth engagement in planetary gearboxes enhances torque density by distributing the load across multiple gears. This design not only improves durability but also minimizes wear, allowing for smoother operation and extended service life. The result is a powerful, reliable vehicle capable of handling demanding tasks.

Track Drive Planetary Gearbox Order

We offer not only the Track Drive Planetary Gearbox for Crawler Tractors but also customization options to meet your specific requirements. To assist us in providing the best solution, please provide the following information:

- Power or Torque of the Planetary Gearbox

- Gear Ratio

- Speed

- Input Type

- Output Type (spline/hollow/solid, etc.)

- Presence of external or radial forces on input or output ends

- Operating Temperature

- Lifetime Requirements

- Special Requirements such as continuous operation, shock loads, etc.

Track Drive Manufacturer

RP Techniek is the sales agent for Ever-power Group in the Netherlands. They specialize in providing high-quality solutions for various machinery needs, particularly focusing on track drive systems. The Track Drive Planetary Gearbox for Crawler Tractors plays a crucial role in ensuring efficient and reliable operation, enhancing the overall performance of your equipment.

We encourage all customers to consider customizing and purchasing these essential components to meet their specific operational requirements. Investing in quality gearboxes will significantly impact your machinery's effectiveness and longevity.

Oanfoljende ynformaasje

| Edited | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...