In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

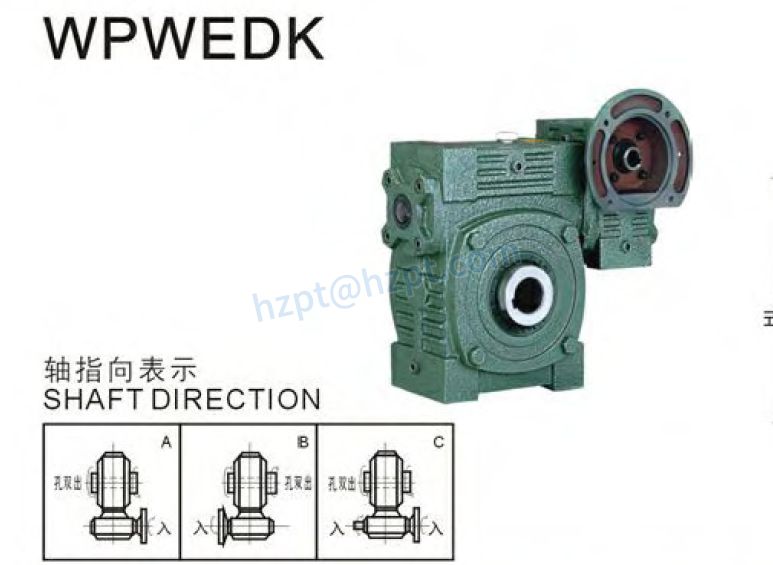

WPWEDK Series Double Stage Cast Iron Worm Gearbox

WPWEDK Series Double Stage Worm Gearboxes

The WPWEDK series double stage worm gearbox is based on a wheeled gear reducer. Made with 45# high-quality steel after heat treatment, the worm is coupled with a tin bronze worm gear. The box is made of high-quality alloy die casting, making it solid, lightweight, and environmentally friendly. It has high heat dissipation performance and a long service life, making it the best choice for modern transmission devices for single-machine transmission and electromechanical integration of production lines. It is widely used in fields such as food machinery, printing machinery, metallurgical machinery, wire and cable machinery, transmission machinery, chemical machinery, textile machinery, printing and dyeing machinery, medicine, and so on.

|

|

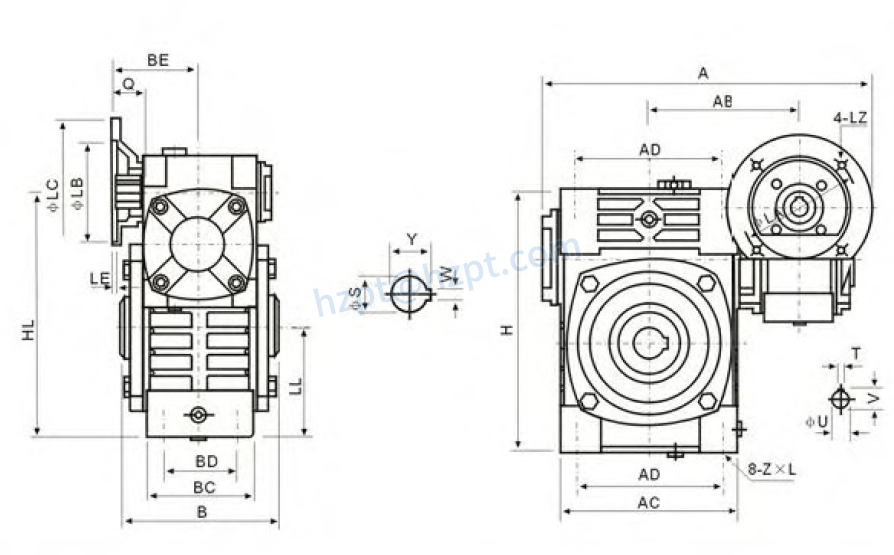

Specifications Parameter

Precautions for Use

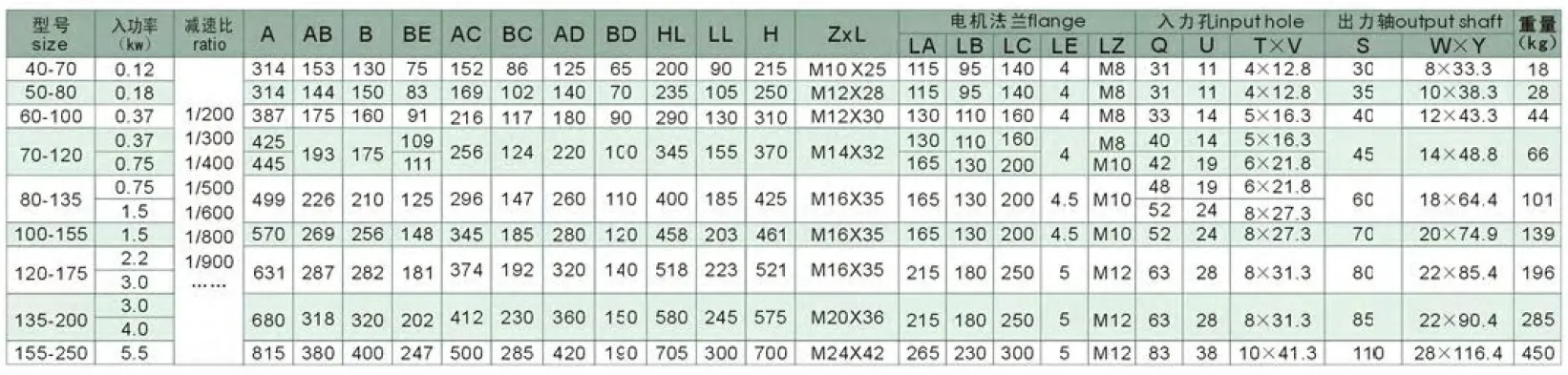

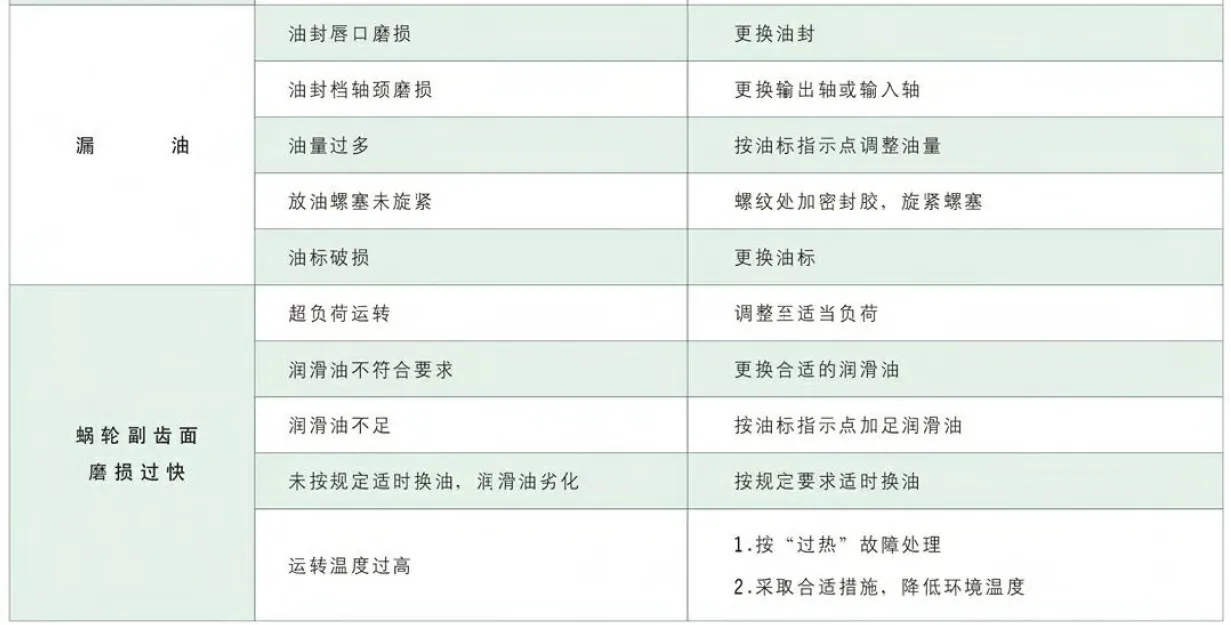

Before using the WPWEDK series double stage worm gearbox, it is essential to ensure that the reducer type structure, center distance specifications, transmission ratio, input shaft connection mode, output shaft structure, input shaft output shaft pointing, and rotation direction meet the requirements. Appropriate type and grade of lubricating oil should be used according to the requirements specified in "Selection of Lubricating Oil Use" on the sample. Oil must control the appropriate amount of refueling according to the requirements of timely oil change, paying particular attention to the first use of 100 hours after replacing new oil. If any abnormal situation occurs during use, stop for inspection on time and refer to the table of "Fault Causes and Solutions."

Solutions and Reasons for the General Faults

How to Maintain Worm Gearbox?

Worm gear reducer applications are widespread in industrial production, and the price is high. If you can pay attention to maintenance, you can not only ensure work efficiency but also significantly increase the service life of the reducer, save corporate expenses, and increase corporate profits. Summarize the following main points of daily maintenance of the worm gear reducer; if you have a better method, you are welcome to contact us to discuss and progress together.

For simple maintenance of the worm gear reducer, you must first pay attention to keeping the machine surface clean, free of dust and grease, with no debris and water in the surrounding environment during maintenance of the worm gear reducer. Regularly test the worm gear and worm with a bearing vibration meter, at the same time making a record of the replacement period of lubricating oil. It must be replaced with new oil after 7-14 days of operation when used for the first time. In future use, the quality of the oil should be checked regularly. For long-term continuous working worm gear reducers, the oil should be changed every 2-3 months; for the reducer whose working time does not exceed 8 hours per day, the oil should be changed every 4-6 months.

If you pay attention to the above points while using the worm gear reducer, we believe your equipment can last longer than others for more than two years, which will significantly save your expenses.

Packing and Transportation

Profil de l'entreprise

Ever-power is a manufacturer of transmission equipment integrating research and development, manufacturing, and sales of speed reducers. With over 25 years of experience in designing, producing, manufacturing, and selling gearboxes, we have served customers in Europe, America, Africa, Asia, and other regions, earning the praise of the market. Our consistent mission and vision over the years have been to introduce advanced production and testing equipment at home and abroad, employing industry professionals and technicians for innovative R&D and manufacturing, and using standardized production management methods to strictly control every aspect of the production of reducers. Our gearboxes are widely used in equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and so on.

We have 600 workers in our factory, which covers 70,000 square meters in Hangzhou. We have been manufacturing 2,500 units of reducers every day since 2012. We are proudly exporting 70% of our products to more than 40 countries all over the world. Our customers come from Italy, Germany, the USA, Canada, Spain, the UK, Mexico, Brazil, Argentina, Turkey, Singapore, and other leading industrial countries worldwide. 30% of them are OEM-made for direct manufacturers of other products.

We warmly welcome customers from other parts of the world to visit us. Seeing is believing. We are confident that you will have confidence in our products after visiting our facility. We have the latest automatic equipment and experienced workers to ensure stable quality and large output. We have the most sophisticated technology and engineering team to support the most demanding requirements on standard and OEM products.

Moteurs électriques à vendre

Electric motors and gearboxes are two essential components of many industrial machines. As a comprehensive transmission equipment manufacturer, we also provide a wide variety of electric motors for our WPWEDK series double stage worm gearbox to meet your specific requirements. Our electric motors are available in various sizes and power capacities and are designed to work in conjunction with our gearboxes to provide optimal performance, stability, and efficiency.

À propos de nous

Ever-power is a well-known manufacturer of worm gearboxes and worm gear reducers in China. Our products include reduction gearboxes, aluminum case worm gearboxes, arc gear cylindrical worm gearboxes, worm gear reducers, in-line helical gearboxes, and cyclo drive reducers, etc. These products feature a rational structure, stable performance, and reliable quality, making them widely used in power, mining, metallurgy, building material, chemical, food, printing, ceramic, paper-making, tobacco, and other industries.

We provide the highest level of service, as well as products of the highest quality and the most competitive prices. We take pride in our ability to create innovative products that meet the needs of our customers and exceed their expectations. Our state-of-the-art manufacturing facility is equipped with the latest technology and staffed by experienced professionals who are committed to providing you with the best possible products and services. We are dedicated to delivering high-quality products that meet the needs of our customers while exceeding their expectations in every way.

Questions et réponses

Q1: What is the WPWEDK series double stage worm gearbox made of?

A1: The WPWEDK series double stage worm gearbox is made of high-quality alloy die casting that makes it solid, lightweight, and environmentally friendly. The worm is made of 45# high-quality steel after heat treatment, and the worm gear is made of tin bronze.

Q2: What precautions should be taken when using the WPWEDK series double stage worm gearbox?

A2: Before using the WPWEDK series double stage worm gearbox, you must ensure that the reducer type structure, center distance specifications, transmission ratio, input shaft connection mode, output shaft structure, input shaft output shaft pointing, and rotation direction meet the requirements. Appropriate type and grade of lubricating oil should be used according to the requirements specified in "Selection of Lubricating Oil Use" on the sample. Oil must control the appropriate amount of refueling according to the requirements of timely oil change, paying particular attention to the first use of 100 hours after replacing new oil. If any abnormal situation occurs during use, stop for inspection on time and refer to the table of "Fault Causes and Solutions."

Q3: What are the maintenance requirements for the WPWEDK series double stage worm gearbox?

A3: To maintain the WPWEDK series double stage worm gearbox, you must keep the machine surface clean, free of dust and grease, with no debris and water in the surrounding environment. Regularly test the worm gear and worm with a bearing vibration meter, at the same time making a record of the replacement period of lubricating oil. It must be replaced with new oil after 7-14 days of operation when used for the first time. For long-term continuous working worm gear reducers, the oil should be changed every 2-3 months. For the reducer whose working time does not exceed 8 hours per day, the oil should be changed every 4-6 months.

Q4: What are the advantages of using electric motors in conjunction with the WPWEDK series double stage worm gearbox?

A4: Electric motors and gearboxes are two essential components of many industrial machines, and when used together, they can provide optimal performance, stability, and efficiency. Our electric motors are available in various sizes and power capacities and are designed to work in conjunction with our gearboxes to ensure the best possible performance.

Q5: What is Ever-power's experience in the design and manufacture of gearboxes?

A5: Ever-power has over 25 years of experience in designing, producing, manufacturing, and selling gearboxes. We have served customers in Europe, America, Africa, Asia, and other regions. Our consistent mission and vision over the years have been to introduce advanced production and testing equipment at home and abroad, employing industry professionals and technicians for innovative R&D and manufacturing.

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...