The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Stepper Worm Gear

The Stepper Worm Gear is a precision mechanical component designed for efficient motion control. Made from high-quality materials such as aluminum and stainless steel, it ensures durability and reliability. The Stepper Worm Gear is primarily used in robotics and automation systems, providing smooth and accurate torque transmission for precise positioning.

Details of Stepper Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 1:10 |

| Max Torque | 5 Nm |

| Input Shaft Diameter | 10 mm |

| Output Shaft Diameter | 20 mm |

| Matériel | Aluminum Alloy |

| Operating Temperature | -40 to 100 °C |

| Poids | 1.5 kg |

Features of Stepper Worm Gear

- High Efficiency: The Stepper Worm Gear is designed to provide high torque and precise control, making it ideal for applications requiring reliable motion transfer.

- Compact Design: Its space-saving design allows for easy integration into various machinery, making it a preferred choice for manufacturers.

- Low Backlash: The Stepper Worm Gear minimizes backlash, ensuring smooth operation and improved accuracy in positioning tasks.

- Durable Materials: Constructed from robust materials, the Stepper Worm Gear is built to withstand wear and tear, ensuring a long service life.

Applications of Stepper Worm Gear in Automation

The Stepper Worm Gear is essential in various automation applications, providing precise control and efficient torque transmission. This innovative gear system is commonly used in CNC machines, robotics, and conveyor systems, where accurate positioning is critical. The Stepper Worm Gear's design allows for smooth operation and minimal backlash, enhancing performance in high-precision tasks. Additionally, its compact form factor makes it ideal for space-constrained environments. With the integration of the Stepper Worm Gear, industries can achieve reliable and effective motion control, significantly improving productivity and operational efficiency.

Manufacturing Process of Stepper Worm Gear

- Material Selection: The first step in the manufacturing process of Stepper Worm Gear is selecting high-quality materials. Typically, materials like carbon steel, stainless steel, and bronze are chosen for their strength and durability. The selection process involves analyzing the application requirements to ensure the Stepper Worm Gear can withstand operational stresses while providing efficient performance. Proper material choice plays a significant role in the longevity and reliability of the gear, making it crucial for the overall manufacturing process.

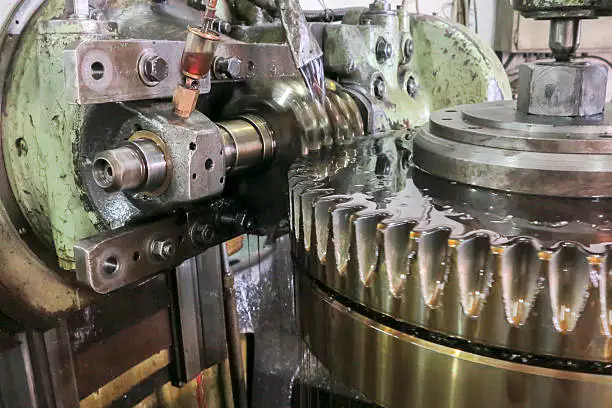

- Machining of Worm Shaft: The next phase involves machining the worm shaft, which is integral to the Stepper Worm Gear assembly. This process usually requires precision CNC (Computer Numerical Control) machining to create the worm profile. The dimensions and tolerances are critically important to ensure smooth interactions between the worm and the worm wheel. Additionally, surface finishing techniques such as grinding or honing are often employed to enhance the surface characteristics, reducing friction and wear during operation.

- Manufacturing the Worm Wheel: After the worm shaft is machined, the production of the worm wheel follows. The worm wheel is typically fabricated using casting or machining methods, depending on the design specifications and material chosen. This part must be designed to engage seamlessly with the worm shaft. The dimensional accuracy and tooth profile are vital, as they directly affect the mechanical efficiency of the Stepper Worm Gear. Quality control measures are implemented at this stage to ensure that the components meet stringent standards.

- Heat Treatment: Heat treatment is a crucial process applied to both the worm shaft and the worm wheel. This step improves the mechanical properties of the Stepper Worm Gear components, such as hardness and wear resistance. The components undergo processes like quenching and tempering, which alter the microstructure of the materials, resulting in enhanced performance under load. Proper heat treatment ensures that the Stepper Worm Gear can operate reliably over extended periods, even in demanding conditions.

- Assembly and Quality Testing: The final step in the manufacturing process involves the assembly of the Stepper Worm Gear. Both the worm shaft and the worm wheel are carefully assembled to ensure proper alignment and functionality. Post-assembly, rigorous quality testing is conducted to identify any deviations from specifications. This may include performance tests under load, inspection for machining errors, and verification of the gear’s operational characteristics. Ensuring high quality at this stage is essential for the overall success and performance of the Stepper Worm Gear.

Worm Gear Supplier in Holland

RP Techniek BV is the authorized sales agent for the Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our product offerings include:

- Stepper Worm Gear: We specialize in high-quality stepper worm gears designed for precision and reliability in various applications.

- Quality Assurance: Our products undergo rigorous testing to ensure they meet the highest quality standards, providing customers with durable and efficient solutions.

- Strength & Expertise: With years of experience in the industry, our team possesses the expertise to meet diverse requirements and offer tailored solutions.

- Excellent Service: We are committed to providing exceptional customer service, ensuring timely delivery and support throughout your purchasing experience.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...