In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

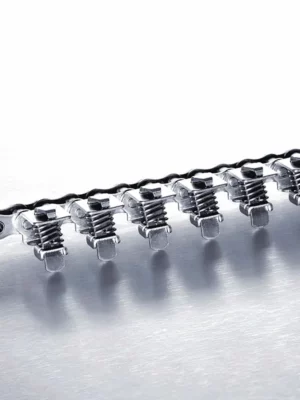

Details of Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5

Product Knowledge Introduction: Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5

1. Overview

The Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5 is an advanced and innovative product designed to meet the specific needs of the metallurgical industry. It offers exceptional performance and durability, making it a preferred choice for horizontal conveyor systems used in various metallurgical processes.

2. Key Features

2.1 High-Quality Stainless Steel Composition

The SSEC81.5 cathode chain is constructed using high-quality stainless steel, ensuring excellent resistance to corrosion, abrasion, and high temperatures. This composition guarantees a longer lifespan and reliable performance even in demanding metallurgical environments.

2.2 Enhanced Electrolysis Efficiency

With its unique design and advanced electrolysis technology, the SSEC81.5 cathode chain maximizes the efficiency of the electrolysis process. It facilitates the smooth flow of electric current, ensuring optimal metal deposition and minimizing energy waste.

3. Superior Durability

The SSEC81.5 cathode chain is engineered to withstand the harsh operating conditions typically found in metallurgical plants. Its superior durability ensures minimal maintenance requirements and reduces downtime, resulting in improved productivity and cost savings.

4. Customizable Design

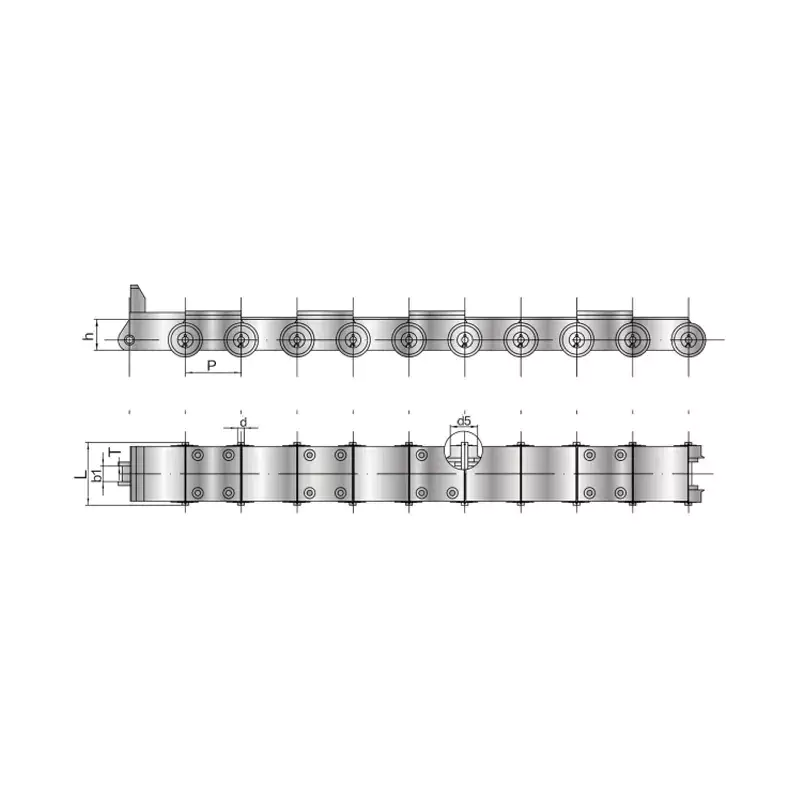

4.1 Modular Structure

The SSEC81.5 cathode chain features a modular design, allowing for easy installation, maintenance, and customization. Its flexible structure enables seamless integration with existing horizontal conveyor systems, providing a tailored solution for different production requirements.

4.2 Adjustable Length

Designed to accommodate varying conveyor widths, the SSEC81.5 cathode chain offers adjustable length options. This adaptability ensures a precise fit and optimal performance, enhancing operational efficiency and product quality.

5. Safety and Environmental Considerations

5.1 Electrolyte Leakage Prevention

The SSEC81.5 cathode chain incorporates an effective sealing system that prevents electrolyte leakage during the electrolysis process. This feature promotes a safer working environment and reduces the risk of contamination in the production system.

5.2 Eco-Friendly Materials

Committed to sustainability, the SSEC81.5 cathode chain is manufactured using eco-friendly materials that comply with international environmental standards. This ensures minimal environmental impact while maintaining product performance and reliability.

6. Applications

The SSEC81.5 cathode chain is specifically designed for horizontal conveyor systems in the metallurgical industry. Its versatility and performance make it suitable for a wide range of applications, including:

- Electrolytic refining

- Metal electrowinning

- Electroplating processes

- Electrochemical synthesis

With its exceptional quality and innovative design, the SSEC81.5 cathode chain is an indispensable component for efficient and reliable metallurgical operations.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV, as the sales agent of Ever-power Group in the Netherlands, proudly presents the Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5. Our unique selling points highlight the exceptional quality and outstanding service that set us apart from the competition. With our strong production capabilities, we ensure that our chains meet the highest industry standards.

In addition to the SSEC81.5 chain, we offer a wide range of other stainless steel roller chains for sale. Our diverse selection caters to various industrial needs and applications, guaranteeing that you will find the perfect chain for your requirements.

At RP Techniek BV, we prioritize customer satisfaction and strive to exceed expectations. Our dedicated team of experts is committed to providing reliable solutions and prompt assistance for all your chain-related needs. Whether you require customization, technical support, or maintenance services, we are here to assist you every step of the way.

Choose our stainless steel metallurgy industry chains and experience the durability, efficiency, and reliability that our products deliver. Contact us now to discuss your specific requirements and let us be your trusted partner for all your chain needs.

How to Select Suitable Sprockets?

When it comes to selecting suitable sprockets, it is important to consider the specific application and the type of chain being used. For the Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5, it is recommended to choose a sprocket that matches the size and pitch of the chain.

At our company, we offer a wide variety of sprockets for sale, including those made from various materials such as stainless steel, cast iron, and plastic. Our sprockets also come in different tooth counts and bore sizes to fit different shaft diameters.

When selecting a sprocket, it is important to consider factors such as the operating conditions, load requirements, and environment. Choosing the right sprocket can help optimize the performance and longevity of both the chain and sprocket.

Check out our selection of sprockets for the Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5 and contact us for assistance in selecting the right sprocket for your specific application.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...