In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

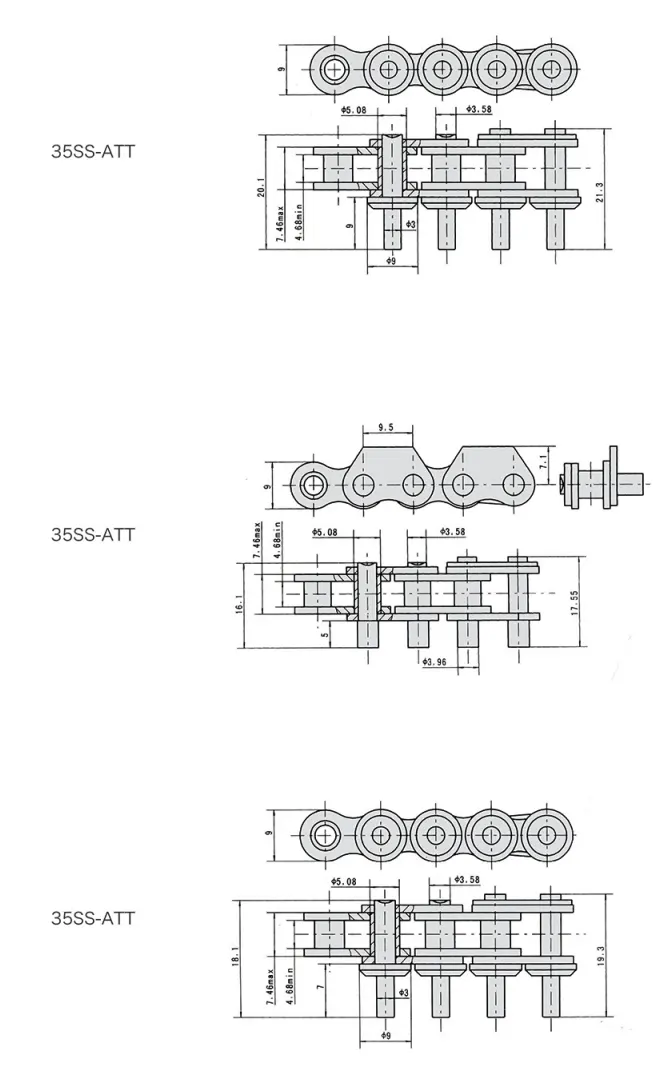

Dimensions of Stainless Steel Chains for Welding Machine

Here are the parameters for this chain:

- Material: Stainless steel

- Size: Varies depending on machine

- Weight: Varies depending on length and size

- Strength: High tensile strength for heavy loads

- Resistance: Resistant to corrosion, rust, and heat

Introduction

Stainless Steel Chains for Welding Machine are essential components used in various welding machines. These chains are specifically designed to provide durability, strength, and reliability in demanding welding applications. With their exceptional resistance to corrosion and high temperatures, they ensure optimal performance and longevity.

1. Superior Stainless Steel Composition

The stainless steel chains for welding machines are crafted using a premium-grade stainless steel composition. This composition includes elements such as chromium, nickel, and molybdenum, which enhance the chains' resistance to corrosion and oxidation. The high-quality stainless steel ensures the chains can withstand harsh welding environments, minimizing the risk of damage and ensuring long-lasting performance.

2. Precision Manufacturing Process

The chains undergo a meticulous manufacturing process to guarantee their exceptional quality and reliability. Advanced machinery and techniques are employed to ensure precise dimensions, accurate link formations, and smooth surfaces. The precision manufacturing process enhances the overall functionality of the chains, allowing them to withstand heavy loads and maintain excellent performance in welding operations.

3. Enhanced Strength and Load Capacity

These stainless steel chains possess excellent strength and load capacity, making them ideal for welding machines. The chains are designed to withstand high tensions, heavy loads, and rigorous welding applications. This exceptional strength ensures that the chains can effectively transfer power and maintain the stability of the welding machine, even under demanding conditions.

4. Resilience to High Temperatures

Stainless Steel Chains for Welding Machine exhibit remarkable heat resistance, enabling them to perform reliably in high-temperature environments. The chains can withstand the heat generated during welding processes without compromising their integrity or functionality. This resilience to high temperatures ensures that the chains remain robust and effective, even during prolonged welding operations.

5. Easy Maintenance and Longevity

These chains are designed for easy maintenance, contributing to their longevity and overall cost-effectiveness. Their stainless steel composition minimizes the need for frequent lubrication or replacement, reducing maintenance efforts and expenses. Additionally, their resistance to corrosion and wear ensures a prolonged lifespan, allowing users to achieve maximum value and productivity from their welding machines.

In conclusion, Stainless Steel Chains for Welding Machine offer exceptional durability, strength, and reliability in demanding welding applications. The superior stainless steel composition, precision manufacturing process, enhanced strength and load capacity, resilience to high temperatures, and easy maintenance contribute to their outstanding performance and longevity. Choose these stainless steel chains to ensure optimal welding machine functionality and maximize productivity.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, as the Netherlands sales agent of Ever-power Group, offers high-quality Stainless Steel Chains for Welding Machine. Our company prides itself on its unique selling points, emphasizing exceptional product quality, excellent service, and a strong manufacturing capability.

Our stainless steel roller chains stand out in the market due to their durability, resistance to corrosion, and reliable performance. Designed specifically for welding machines, these chains ensure smooth and efficient operation, even in demanding industrial environments.

With our extensive experience and expertise, we understand the importance of providing reliable solutions to our customers. We are committed to delivering products that meet the highest standards, ensuring customer satisfaction.

In addition to Stainless Steel Chains for Welding Machine, we also offer a wide range of other stainless steel roller chains. Whether you need chains for conveyors, food processing equipment, or any other applications, we have the right solution for you.

Sprockets for Sale

The Stainless Steel Chains for Welding Machine are the perfect complement to the sprockets we offer. At our company, we provide a wide variety of different types of sprockets for sale to meet your specific needs.

Our sprockets are meticulously designed and manufactured with high-quality materials to ensure durability and optimal performance. They are precisely engineered to fit perfectly with the Stainless Steel Chains for Welding Machine, creating a reliable and efficient system.

Whether you require sprockets for industrial applications, agricultural machinery, or any other machinery requiring power transmission, we have the right solution for you. Our extensive range includes sprockets of various sizes, teeth configurations, and materials.

With our commitment to delivering exceptional products, you can trust that our sprockets are built to withstand the toughest conditions and provide long-lasting reliability. We prioritize customer satisfaction and strive to exceed your expectations with our top-notch sprockets.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...