In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Caractéristiques

- Type: RF212

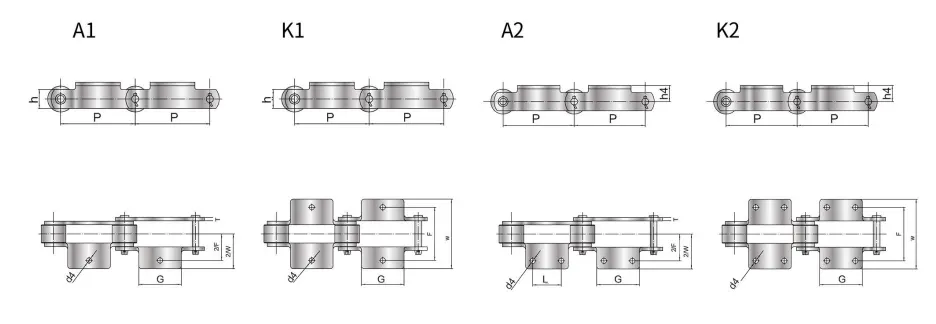

- Conveyor Chain with A1 K1 A2 K2 Attachment

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212 features the following parameters:

- Chain Type: RF

- Attachment Type: A1, K1, A2, K2

- Model: RF212

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

1. Overview

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212 is a high-quality chain specifically designed for conveyor systems. This chain offers exceptional durability and precision for various industrial applications. With its unique attachment design, it provides efficient and reliable transportation of materials.

2. Features and Benefits

2.1. Robust Construction

Constructed with premium materials and advanced manufacturing techniques, the RF Type Conveyor Chain ensures excellent strength and durability. It can withstand heavy loads and harsh operating conditions, making it perfect for demanding industrial environments.

2.2. Enhanced Efficiency

The A1 K1 A2 K2 Attachment design of RF212 chain allows for smooth and seamless material handling. Its precise engineering minimizes friction and ensures efficient power transmission, resulting in improved productivity and reduced downtime.

2.3. Versatility

This chain is highly versatile and can be used in a wide range of industries, including automotive, food processing, packaging, and more. Its adaptability and customizable options make it suitable for various conveyor applications.

2.4. Extended Service Life

Thanks to its superior build quality and resistance to wear, the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212 offers a long service life. This reduces the need for frequent replacements, leading to cost savings and increased operational efficiency.

3. Technical Specifications

| Chain Type | RF212 |

|---|---|

| Attachment Type | A1 K1 A2 K2 |

| Pitch | XX mm |

| Roller Diameter | XX mm |

| Breaking Load | XX kN |

| Weight per Meter | XX kg |

4. Application Areas

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212 is commonly used in the following applications:

- Automotive assembly lines

- Material handling systems

- Packaging and bottling industries

- Food processing plants

- Warehouse logistics

5. Installation and Maintenance

Proper installation and regular maintenance are crucial to ensure optimal performance and longevity of the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212. It is recommended to follow the manufacturer's guidelines for installation, lubrication, and inspection procedures.

Regular cleaning, lubrication, and periodic inspection of the chain and attachments will help identify any issues and prevent potential downtime. It is important to replace worn-out components promptly to maintain the chain's efficiency and prevent damage to other conveyor system parts.

With its robust construction, enhanced efficiency, versatility, and extended service life, the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212 is an excellent choice for industries that rely on efficient and reliable material handling systems. Its superior performance and durability make it a valuable asset in optimizing industrial processes.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We take pride in providing high-quality stainless steel roller chains to meet our customers' needs. Our RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212 is a unique product that highlights our exceptional selling point, which emphasizes product quality and superior service.

Our company values the importance of producing reliable and durable products. Our stainless steel roller chains go through a rigorous quality control process to ensure that our customers receive only the best. In addition to our high-quality products, we also provide excellent customer service to ensure that our customers are satisfied with their purchase.

Our production capabilities are also an advantage. We have state-of-the-art machinery and experienced professionals who oversee the entire production process, from design to packaging. This ensures that our products are made with precision and attention to detail.

In addition to our RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212, we offer a wide variety of other stainless steel roller chains for sale. Our inventory includes various sizes and specifications to meet our customers' unique needs.

Don't settle for anything less than exceptional quality and service. Choose RP Techniek BV for all of your stainless steel roller chain needs.

Sprockets for Sale

When it comes to the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF212, finding the perfect matching sprockets is crucial. At our company, we offer a wide range of sprockets to suit your needs.

Our sprockets are designed with precision and durability in mind. They are expertly crafted to ensure seamless compatibility with the RF Type Conveyor Chain RF212 and its attachments A1 K1 A2 K2. Whether you require a smaller size for lighter loads or a larger size for heavier applications, we have the right sprocket for you.

Our extensive selection includes various types of sprockets, such as single-row, double-row, and multi-row sprockets. Each sprocket is made from high-quality materials, ensuring long-lasting performance and reliability.

With our sprockets, you can expect smooth operation, reduced wear and tear, and increased productivity. Whether you need sprockets for industrial machinery, agricultural equipment, or any other application, we have the solution.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...