In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details

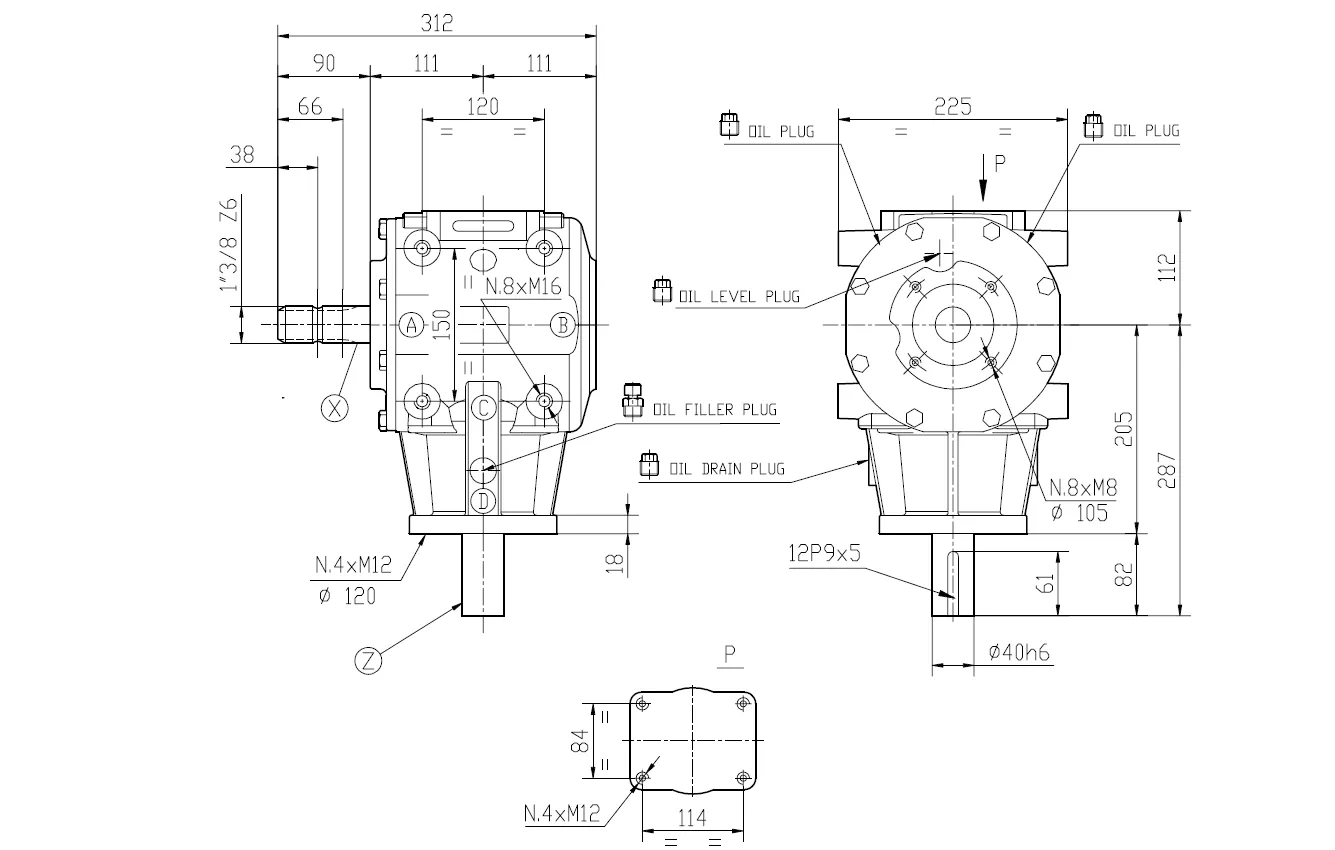

This Flail Mower Gearbox is a replacement for the Comer Code T-290A 1:1.86. Here are the details:

| Description |

Flail Mower Gearboxes - Replacement of Comer Gearbox T-290A 1:1.86

|

|---|---|

| Application |

|

| Consists of |

|

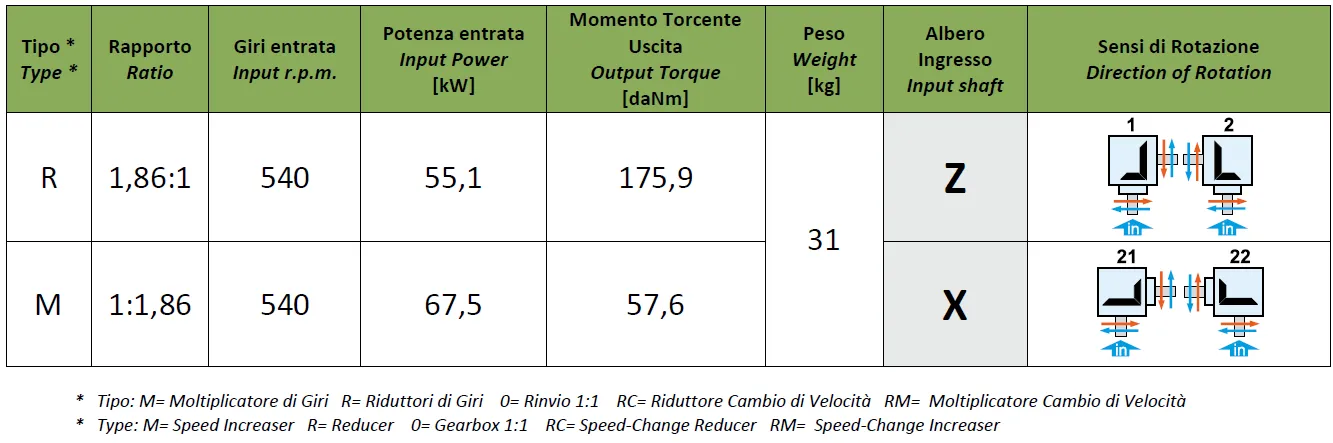

| Technical information |

|

| Max. output torque |

175.9?daNm

|

| Contains oil |

Non

|

| Max. oil capacity |

2.3?l

|

| Max. oil change interval |

500?h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Poids |

30?kg

|

| Gear arrangement Increasing |

25 - 26

|

| Gear arrangement Reducing |

5 - 6

|

| Input power kW / HP Increasing |

62.5 / 85?kW/HP

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

55.1 / 75?kW/HP

|

| Output Torque DaNm Increasing |

57.6?daNm

|

| Ratio Increasing |

1:1.86

|

| Ratio Reducing |

1.86:1

|

| Shaft X |

1 3/8" (6) (A)

|

| Shaft Y |

1 3/8" (6) (A)

|

| Shaft Z |

1 3/8" (6) (B)

|

Introduction

The Flail Mower Gearboxes are an essential part of a flail mower. These gearboxes transmit power from the tractor to the flail mower blades, allowing them to cut through dense vegetation. The Comer Code T-290A 1:1.86 gearbox is a popular choice for flail mowers, but over time, it may become worn or damaged and require replacement. In this article, we will discuss the replacement process for the Comer Code T-290A 1:1.86 gearbox.

Step 1: Remove the Old Gearbox

The first step in replacing the Comer Code T-290A 1:1.86 gearbox is to remove the old one. Begin by disconnecting the power take-off (PTO) shaft from the tractor. Then, use a socket wrench to remove the bolts that attach the gearbox to the mower deck. Carefully slide the gearbox out of its housing and set it aside.

Step 2: Install the New Gearbox

Once the old gearbox has been removed, it's time to install the new one. Carefully slide the new gearbox into the housing, making sure it is properly aligned. Use a socket wrench to attach the gearbox to the mower deck using the bolts provided. Then, reattach the PTO shaft to the tractor.

Step 3: Fill with Oil

After the new gearbox has been installed, it's important to fill it with oil. This will ensure that the gearbox is properly lubricated and will function correctly. Check the manufacturer's specifications for the correct type and amount of oil to use. Use a funnel to add the oil to the gearbox, and be sure not to overfill it.

Step 4: Test the Gearbox

Once the new gearbox has been installed and filled with oil, it's important to test it before using the flail mower. Engage the PTO and run the mower for a few minutes, making sure the gearbox is functioning properly. Listen for any unusual noises or vibrations, and check for any leaks. If everything appears to be working correctly, the new gearbox is ready for use.

Conclusion

Replacing the Comer Code T-290A 1:1.86 gearbox on a flail mower is a straightforward process that can be completed with basic tools. With the new gearbox properly installed and filled with oil, the flail mower will be able to cut through dense vegetation with ease, making it an essential tool for any farmer or landscaper.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We specialize in supplying high-quality agricultural gearboxes, including Flail Mower Gearboxes that replace Comer Code T-290A 1:1.86. Our unique selling points include exceptional product quality and reliable customer service, providing our clients with the best possible experience.

We take great pride in our production capabilities, utilizing the latest technology and equipment to ensure our products meet the highest industry standards. Our gearboxes are designed to perform optimally even under extreme conditions, providing unparalleled performance and durability.

Aside from agricultural gearboxes, we also offer a wide range of other agricultural parts and transmission components for sale. Our extensive inventory includes all types of agricultural machinery parts, providing our clients with a one-stop solution for all their agricultural needs.

At RP Techniek BV, our commitment to quality and customer satisfaction is unmatched. We strive to provide our clients with the best possible products and services, ensuring their complete satisfaction every step of the way.

Please see the attached image for an overview of our agricultural gearbox manufacturers:

PTO Shafts for Agricultural Gearboxes

The PTO shafts play a crucial role in connecting agricultural gearboxes, such as the Flail Mower Gearbox Replacement of Comer Code T-290A 1:1.86. These shafts serve as the essential link between the power source and the agricultural gearbox, allowing for the transfer of power to drive various agricultural machinery.

At our company, we understand the importance of reliable and efficient PTO shafts in agricultural applications. That is why we offer a wide range of high-quality PTO shafts specifically designed for agricultural gearboxes. These shafts are meticulously crafted to withstand the demanding conditions of farm work, ensuring optimal performance and longevity.

Our PTO shafts are engineered using top-grade materials and advanced manufacturing techniques, ensuring exceptional strength, durability, and precision. With our extensive selection, you can find the perfect PTO shaft that matches the specifications of your agricultural gearbox, including the Flail Mower Gearbox Replacement of Comer Code T-290A 1:1.86.

By choosing our company, you can have peace of mind knowing that you have access to reliable and high-performance PTO shafts for your agricultural gearbox needs. Contact us today to explore our range of PTO shaft options and take advantage of our exceptional products and services.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...