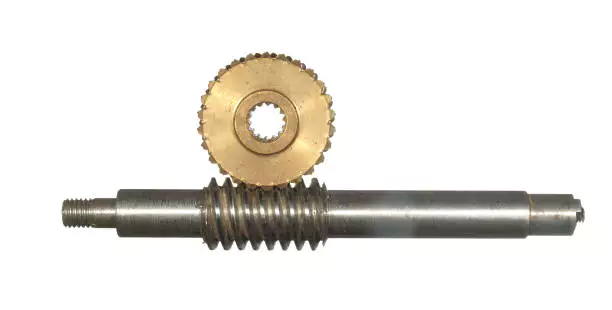

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Electric Motor Worm Gear

The Electric Motor Worm Gear is a robust mechanical component designed to provide efficient power transmission. Made from high-quality materials like aluminum and steel, it ensures durability and longevity. This Electric Motor Worm Gear is primarily used in applications requiring speed reduction and increased torque, making it essential in various industrial machines.

Details of Electric Motor Worm Gear

| Parameter | Value |

|---|---|

| Power Rating | 0.5 - 5 HP |

| Gear Ratio | 5:1 - 100:1 |

| Input Voltage | 220V / 380V |

| Efficiency | 85% - 95% |

| Output Torque | 10 - 100 Nm |

| Operating Temperature | -10°C to 40°C |

| Poids | 10 - 50 kg |

Features of Electric Motor Worm Gear

- High Efficiency: The Electric Motor Worm Gear is designed to provide high torque output with minimal energy loss, making it ideal for various applications where efficiency is crucial.

- Compact Design: Its compact size allows for easy installation in tight spaces, making the Electric Motor Worm Gear suitable for a wide range of machinery and equipment.

- Durability: Built with high-quality materials, the Electric Motor Worm Gear offers long-lasting performance even in harsh environments, reducing maintenance needs.

Applications of Electric Motor Worm Gear

The Electric Motor Worm Gear is an essential component in various industries, providing efficient power transmission and precise motion control. These gears are widely used in applications such as robotics, conveyor systems, agricultural machinery, and automated equipment. Their unique design allows for high torque and compact installation, making them ideal for space-constrained environments. The Electric Motor Worm Gear is particularly beneficial in scenarios requiring smooth operation and minimal backlash, ensuring reliable performance in demanding applications.

Manufacturing Process of Electric Motor Worm Gear

- Material Selection: The first step in the manufacturing process of the Electric Motor Worm Gear involves selecting high-quality materials. Typically, a combination of metals such as steel or bronze is used to ensure durability and performance. These materials are chosen based on their strength and resistance to wear, which are crucial for the efficiency of the Electric Motor Worm Gear. The right material selection impacts the overall longevity and reliability of the gear in various applications.

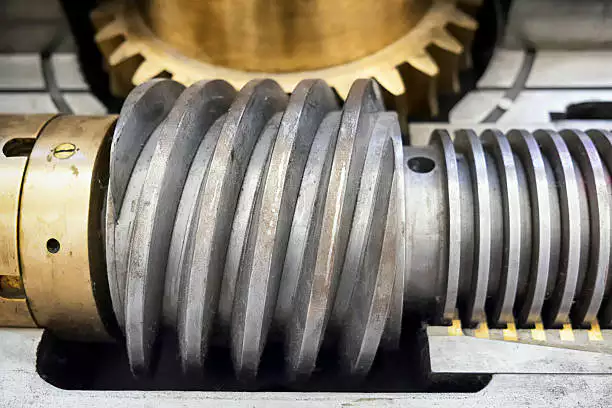

- Machining: Once the materials are chosen, the machining process begins. This involves using precision equipment to shape the worm and worm gear to exact specifications. Techniques such as turning, milling, and grinding are employed to achieve the desired dimensions and surface finishes. This step is critical as it affects the meshing and performance of the Electric Motor Worm Gear, ensuring smooth operation and minimizing friction between the components.

- Heat Treatment: To enhance the mechanical properties of the Electric Motor Worm Gear, heat treatment is applied. This process involves heating the machined components to a specific temperature and then cooling them in a controlled manner. The heat treatment process increases hardness and strength while reducing brittleness, resulting in a more resilient worm gear that can withstand heavy loads and prolonged use in electric motor applications.

- Assembly: After the individual components are prepared, the assembly of the Electric Motor Worm Gear commences. This includes carefully fitting the worm onto the worm gear to ensure proper alignment and engagement. The assembly process is essential in ensuring that the gear operates efficiently, without excessive backlash or play. Proper assembly techniques contribute significantly to the performance and reliability of the overall system in which the Electric Motor Worm Gear is utilized.

- Quality Control: Finally, rigorous quality control measures are implemented to ensure that the Electric Motor Worm Gear meets industry standards and specifications. This includes dimensional inspections, performance testing, and material analysis. Quality control is vital to guarantee that the gear functions correctly under operational conditions, providing users with peace of mind regarding performance and durability in their electric motor systems.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for the Ever-power Group, and we are proud to be one of the top ten worm gear suppliers in the Netherlands.

Our product line includes a range of electric motor worm gears, known for their exceptional quality and performance. Here are some key points about our offerings:

- High-quality materials: We use premium components to ensure reliability and durability in every product.

- Top-notch craftsmanship: Our manufacturing process adheres to strict industry standards, guaranteeing superior quality.

- Robust capabilities: With extensive industry experience, we have the expertise to meet diverse customer needs.

- Excellent customer service: Our team is dedicated to providing responsive and knowledgeable support to every client.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...