The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

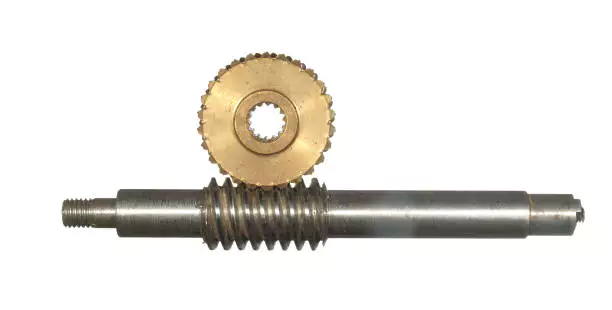

Duplex Worm Gear

The Duplex Worm Gear is a specialized mechanical component designed for efficient power transmission. Made from high-strength materials, it features a Worm Gear that interacts with a Worm Wheel to provide smooth motion. The Worm Shaft and Worm Screw enhance its durability, making it ideal for various industrial applications.

Details of Duplex Worm Gear

| Parameter | Spécification |

|---|---|

| Gear Ratio | 10:1 |

| Matériel | Alloy Steel |

| Output Torque | 150 Nm |

| Input Shaft Diameter | 20 mm |

| Output Shaft Diameter | 25 mm |

| Efficiency | 95% |

| Operating Temperature | -10 to 80 °C |

Features of Duplex Worm Gear

- High Efficiency: Duplex Worm Gear systems provide superior performance by minimizing friction between the Worm Gear and Worm Wheel, leading to enhanced efficiency in power transmission.

- Compact Design: The compact nature of the Worm Shaft allows for a space-saving solution, making it ideal for applications with limited space requirements.

- Durability: Constructed with high-quality materials, Duplex Worm Gear systems are built to withstand heavy loads and resist wear, ensuring a long lifespan.

- Versatility: The Worm Screw design offers flexibility in various industrial applications, making it suitable for both horizontal and vertical mounting setups.

How Duplex Worm Gear Operates

The Duplex Worm Gear is a sophisticated mechanism designed for efficient power transmission. Utilizing a Worm Gear and Worm Wheel, it converts rotary motion into linear movement. The Worm Shaft, which houses the Worm Screw, plays a vital role in this process by engaging with the Worm Wheel to create a gear reduction. This design not only provides high torque output but also enhances durability and reliability in various applications. The unique structure of the Duplex Worm Gear allows for smooth operation and minimal backlash, making it ideal for precise control in machinery.

Manufacturing Process of Duplex Worm Gear

- Material Selection: The manufacturing of Duplex Worm Gear begins with the careful selection of high-quality materials. Typically, steel alloys are preferred due to their strength and durability. The properties of the material directly influence the performance of the Worm Gear, Worm Wheel, and Worm Shaft. High tensile strength and resistance to wear are crucial to ensure longevity and efficient power transmission. The right choice of materials helps in achieving optimal hardness and toughness, essential for the operational demands of the gear system.

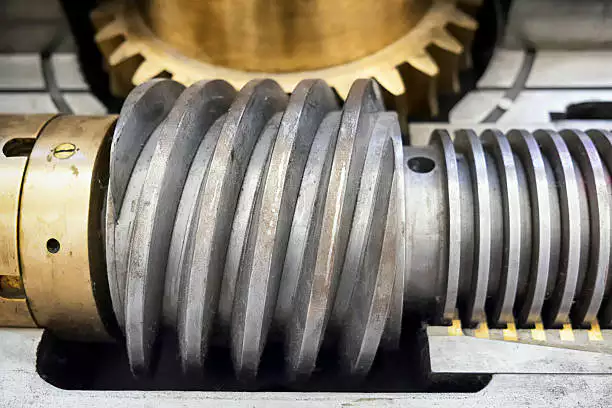

- Machining the Worm Shaft: After material selection, the production process moves to machining the Worm Shaft. This step involves using advanced CNC machines to precisely cut and shape the shaft according to the required specifications. Accurate machining is crucial as it directly affects the fit and interaction with the Worm Gear and Worm Wheel. A well-machined Worm Shaft ensures smooth rotation and minimizes friction, enhancing the overall efficiency of the gear system. Quality checks are performed at this stage to ensure compliance with design standards.

- Creating the Worm Gear and Worm Wheel: The next step involves manufacturing the Worm Gear and Worm Wheel. This process often utilizes hobbing or shaping techniques to create the intricate tooth profiles essential for engaging the Worm Screw effectively. The design must ensure an optimal contact pattern for efficient energy transfer. Each component is manufactured with precision to ensure compatibility with the Worm Shaft, which ultimately enhances the mechanical advantages of the Duplex Worm Gear system. Rigorous testing is conducted to verify the strength and durability of these components.

- Assembly and Quality Control: Following the individual component manufacturing, the assembly of the Duplex Worm Gear system takes place. This stage involves carefully fitting the Worm Shaft, Worm Gear, and Worm Wheel together, ensuring that all components align correctly for optimal performance. Quality control checks are essential at this stage to prevent issues such as misalignment or excessive play, which could lead to premature failure. Final testing under various loads is performed to confirm the operational efficiency and reliability of the entire assembly before it is deemed ready for use.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

Our Duplex Worm Gear products stand out due to their exceptional quality and durability. Key features of our offerings include:

- Top-notch Quality: Our worm gears are manufactured using high-grade materials, ensuring reliability and longevity.

- Precision Engineering: Each product is crafted with precision, meeting stringent industry standards.

- Strong Expertise: With years of experience, our team provides unmatched expertise in the field.

- Exceptional Customer Service: We prioritize customer satisfaction and offer responsive support throughout your purchasing journey.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...