In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Caractéristiques

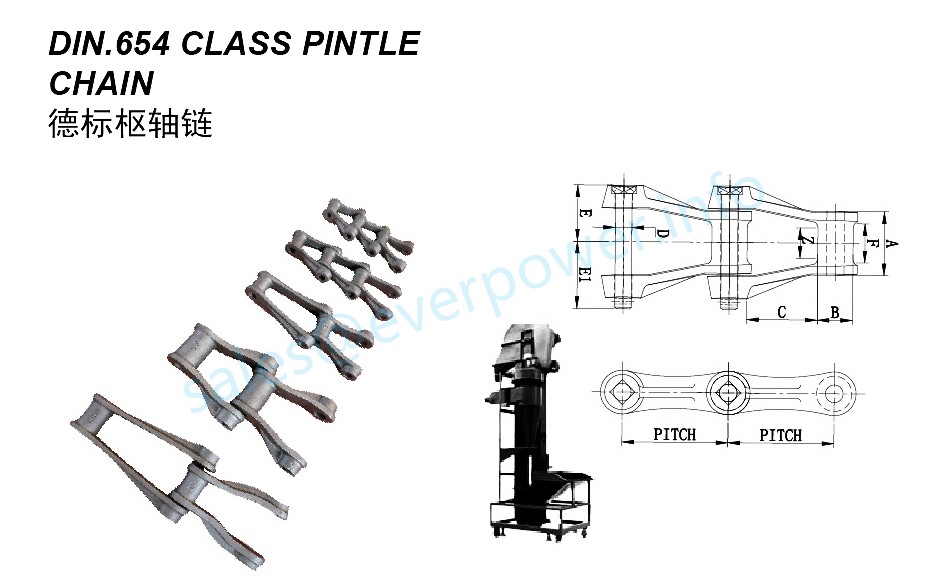

The DIN654 Class Pintle Chain is characterized by the following parameters:

| DIN654 CHAIN NO. |

PITCH IN INCHES | UN | B | C | D | E | E1 | F | Z | MAXIMUM WORKING LOAD KGS. |

AVERAGE ULTIMATE STRENGTH KGS |

WEIGHT PER METRE KG. |

| 40 | 38.7 | 24 | 14 | 24.7 | 7 | 21 | 27 | 18 | 13 | 360.00 | 1800.00 | 2.1 |

| 41 | 41.5 | 28 | 17 | 24.5 | 8 | 25 | 33 | 25 | 14 | 600.00 | 1800.00 | 3.6 |

| 42 | 42 | 33 | 19 | 23 | 9 | 30 | 37 | 24.5 | 16 | 360.00 | 2300.00 | 4.5 |

| 59 | 59.5 | 38 | 21 | 38.5 | 9 | 34.5 | 43.5 | 29 | 20 | 460.00 | 2300.00 | 4.2 |

| 63 | 63 | 38.5 | 21 | 42 | 10 | 34 | 41 | 29 | 20 | 480.00 | 2400.00 | 4.2 |

| 65 | 65.5 | 44 | 25 | 40.5 | 12 | 40 | 50 | 26 | 23 | 760.00 | 3800.00 | 6.8 |

| 85 | 85 | 45 | 27 | 58 | 14 | 43 | 52 | 33 | 24 | 800.00 | 4000.00 | 7.7 |

| 87 | 87 | 60 | 35 | 52 | 17 | 54 | 66 | 45.5 | 32 | 1000.00 | 5000.00 | 12.0 |

| 100 | 100 | 42 | 23 | 77 | 12 | 37.5 | 47.5 | 32 | 23 | 600.00 | 3000.00 | 4.4 |

| 100A | 100 | 41 | 27 | 73 | 13 | 39.5 | 49.5 | 28 | 23 | 640.00 | 3200.00 | 5.5 |

| 100B | 100 | 54 | 30 | 70 | 15 | 51 | 59 | 40 | 32 | 900.00 | 4500.00 | 9.0 |

| 100D | 100 | 51 | 33.5 | 66.5 | 17 | 46 | 59 | 28 | 23 | 1320.00 | 6600.00 | 11.3 |

| 135 | 134.5 | 43 | 23 | 111.5 | 12 | 40 | 50 | 33.5 | 24 | 640.00 | 3200.00 | 4.1 |

| 135A | 135 | 47 | 27 | 108 | 15 | 44 | 54 | 33 | 24 | 700.00 | 3500.00 | 5.0 |

| 136 | 136.5 | 47 | 43 | 93.5 | 17 | 50 | 62 | 30.5 | 27 | 1200.00 | 6000.00 | 9.5 |

Introduction

Welcome to our detailed product knowledge introduction for DIN654 Class Pintle Chain. In this article, we will explore the various aspects of this high-quality chain, its features, applications, and benefits. Let's dive in!

1. What is DIN654 Class Pintle Chain?

DIN654 Class Pintle Chain is a specialized type of chain that is widely used in industries where heavy-duty conveying and power transmission are required. It is designed to withstand demanding operating conditions and provide reliable performance.

2. Construction and Design

The DIN654 Class Pintle Chain consists of precision-machined steel pins and link plates that are interconnected to form a strong and durable chain assembly. These chains are manufactured using advanced engineering techniques to ensure maximum strength and longevity.

3. Key Features

Exceptional Durability: The DIN654 Class Pintle Chain is built to withstand heavy loads and high-speed applications, making it ideal for demanding industrial environments.

Superior Wear Resistance: The chain's high-quality materials offer excellent resistance against wear and abrasion, ensuring prolonged service life.

Optimal Performance: With precise construction and design, this chain delivers smooth and reliable operation, minimizing downtime and maximizing productivity.

4. Applications

The DIN654 Class Pintle Chain finds applications in various industries, including:

Mining and Quarrying

Construction

Agriculture

Material Handling

Power Generation

5. Advantages of DIN654 Class Pintle Chain

Increased Efficiency: The chain's excellent performance and smooth operation contribute to enhanced productivity and operational efficiency.

Reliable Power Transmission: DIN654 Class Pintle Chain ensures consistent power transmission, enabling the smooth operation of machinery and equipment.

Long Service Life: Thanks to its superior durability and wear resistance, this chain offers an extended service life, reducing the need for frequent replacements.

6. Conclusion

In summary, DIN654 Class Pintle Chain is a reliable and high-performance chain that excels in demanding industrial applications. Its exceptional durability, wear resistance, and optimal performance make it a preferred choice for industries requiring heavy-duty conveying and power transmission. Experience the reliability and efficiency of DIN654 Class Pintle Chain for your business!

Choose Our Malleable Casting Chains

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We specialize in providing high-quality malleable cast iron chains, with a particular focus on DIN654 Class Pintle Chain. Our chains stand out due to their unique selling points, emphasizing product quality, exceptional service, and our strong manufacturing capabilities.

In addition to our malleable casting chains, we also offer a wide range of other types of casting chains. With our diverse selection, you can find the perfect chains to meet your specific needs.

Sprockets for Sale

When it comes to choosing the right chain wheel to go with your DIN654 Class Pintle Chain, there are a variety of factors to consider. The most important of these is to ensure that the pitch of the chain and the pitch of the sprocket match. This will ensure proper engagement between the two and prevent slippage or other issues that can arise if the chain and sprocket are not compatible.

At our company, we offer a wide range of sprockets that are designed to work seamlessly with DIN654 Class Pintle Chains. Our sprockets are made from high-quality materials and are available in a variety of sizes and configurations to meet the specific needs of your application. Whether you need a single sprocket or a complete set, we have you covered.

Some of the different types of sprockets we offer include:

- Standard sprockets

- Double pitch sprockets

- Taper lock sprockets

- Weld-on sprockets

- Idler sprockets

No matter what type of sprocket you need, we can help you find the right one for your application. Contact us today to learn more about our sprockets for sale.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...