In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Caractéristiques

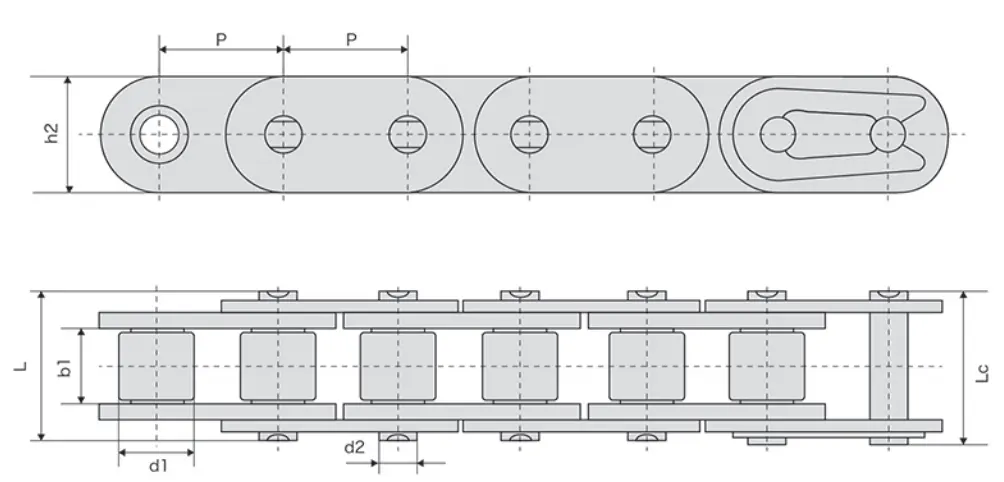

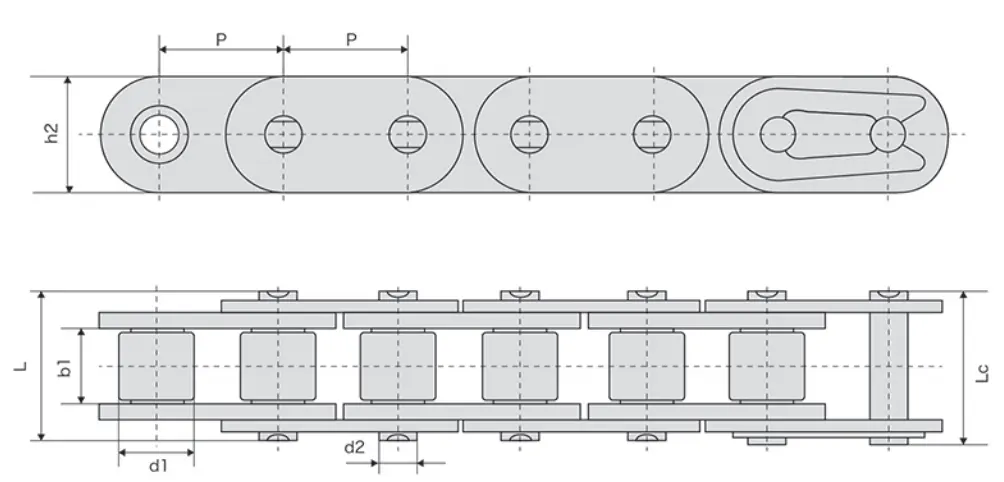

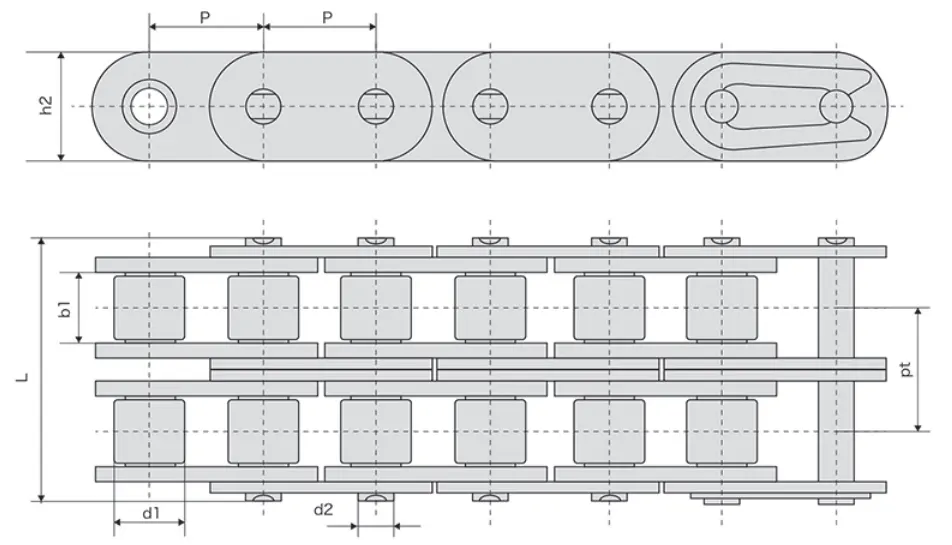

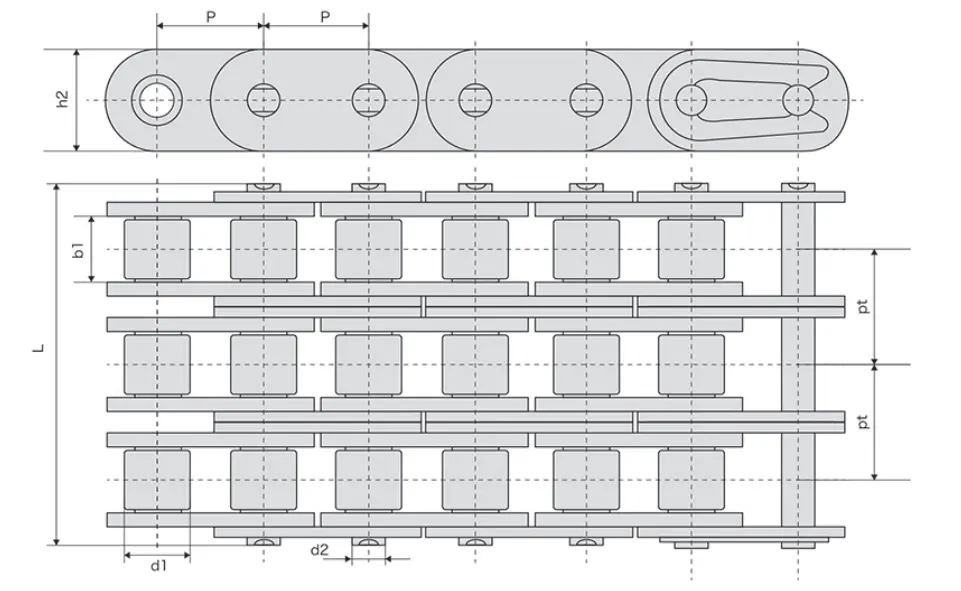

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates has the following parameters:

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

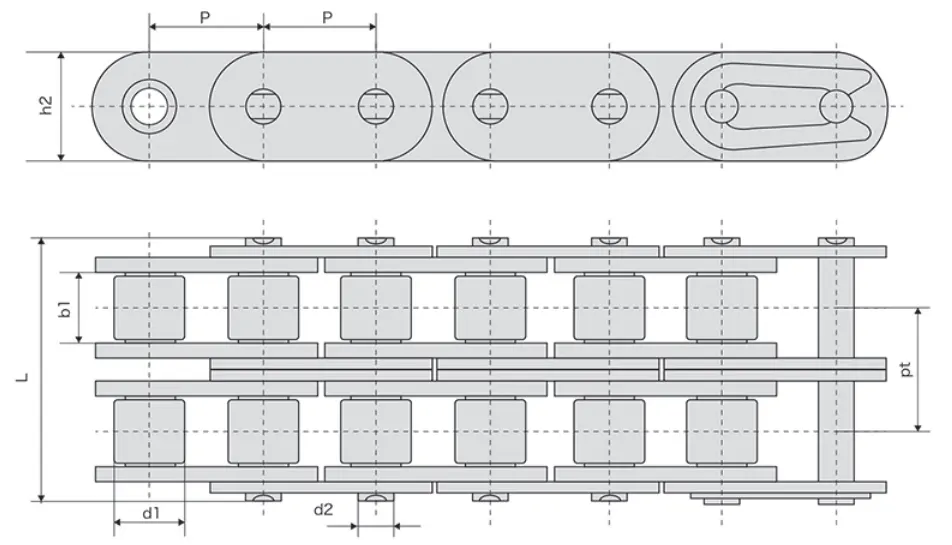

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

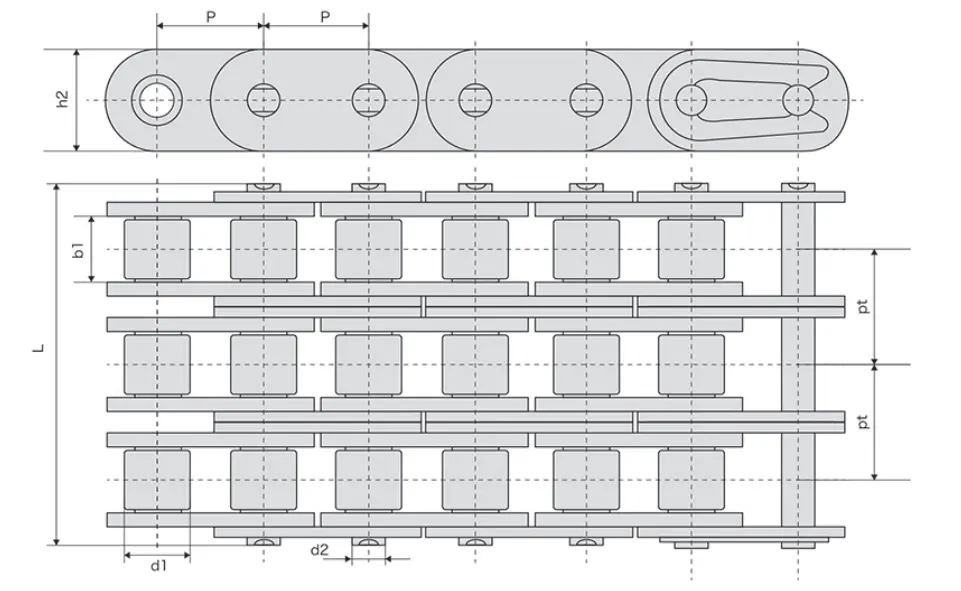

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Introduction

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is a premium-quality roller chain that is designed for heavy-duty industrial applications. It is constructed using high-grade stainless steel, which makes it highly resistant to corrosion, wear, and other forms of damage. This roller chain is suitable for use in harsh environments where conventional roller chains are prone to failure.

Features

1. Corrosion Resistance

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is made using high-grade stainless steel, which makes it highly resistant to corrosion. This means that it can be used in harsh environments such as chemical processing plants, food processing facilities, and marine applications without the risk of rust and other forms of corrosion.

2. Wear Resistance

Stainless steel is known for its high wear resistance, which makes it an ideal material for use in industrial applications. The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is designed to withstand high levels of wear and tear, and can be used in applications where conventional roller chains are likely to fail.

3. High Strength

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is designed to provide high levels of strength and durability. It can withstand heavy loads and high levels of stress without the risk of failure. This roller chain is suitable for use in heavy-duty applications such as mining, construction, and agriculture.

4. Wide Temperature Range

Stainless steel is known for its ability to withstand extreme temperatures. The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates can operate in temperatures ranging from -40¡ãC to 400¡ãC, making it suitable for use in a wide range of applications.

5. Easy Maintenance

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is designed for easy maintenance. It can be easily cleaned and lubricated, which helps to extend its lifespan and ensure optimal performance. This roller chain requires minimal maintenance, which helps to reduce downtime and increase productivity.

Applications

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is suitable for use in a wide range of applications, including:

- Food and beverage processing

- Chemical processing

- Marine applications

- Mining

- Construction

- Agriculture

Conclusion

The C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality roller chain that is designed for heavy-duty industrial applications. It is made using high-grade stainless steel, which makes it highly resistant to corrosion, wear, and other forms of damage. This roller chain is suitable for use in harsh environments where conventional roller chains are prone to failure. Its features such as corrosion and wear resistance, high strength, wide temperature range, and easy maintenance make it a reliable and cost-effective solution for industrial applications.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the authorized sales agent for Ever-power Group in the Netherlands. We specialize in providing top-quality C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates. With our unique selling points, we emphasize the exceptional product quality, outstanding services, and our strong manufacturing capabilities.

Our stainless steel roller chains are built to last, offering superior durability and reliability. Whether you need chains for industrial applications or specific machinery, we have a wide range of options available to suit your requirements.

At RP Techniek BV, we take pride in delivering high-performance roller chains that meet the highest industry standards. Our team of experts ensures that every chain is manufactured with precision and attention to detail, giving you peace of mind knowing that you are investing in a reliable and efficient product.

Explore our extensive collection of stainless steel roller chains and choose the perfect solution for your needs. Visit our website or contact us today for more information.

Sprockets for Sale

When it comes to finding the perfect match for the C50SS-3 Triplex Stainless Steel Roller Chain with Straight Side Plates, look no further than our wide selection of sprockets. At our company, we provide a variety of different types of sprockets to meet your specific needs.

Our range of sprockets includes options with varying tooth counts, bore sizes, and materials. Whether you require a smaller sprocket for high-speed applications or a larger sprocket for heavy-duty machinery, we have you covered.

With our durable and reliable sprockets, you can ensure smooth and efficient power transmission in your machinery. Each sprocket is designed with precision and built to withstand demanding environments, ensuring long-lasting performance.

Take a look at our extensive collection of sprockets below:

For more information or to place an order, please contact our sales team. We are here to assist you in finding the perfect sprocket for your application.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...