In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of 902 Sugar Mill Chain:

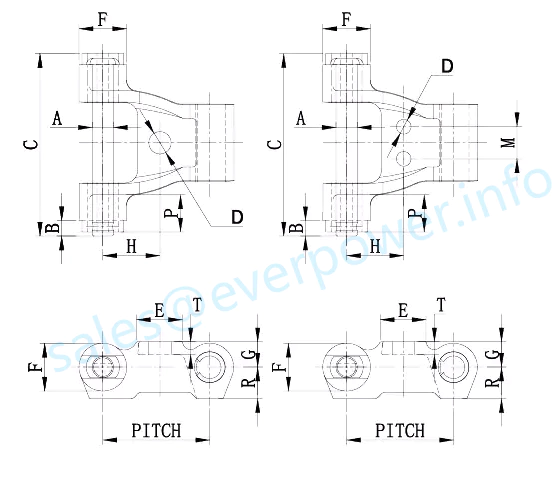

The following are the parameters of the chain:

| Chain No. | Pitch | UN | C | D | E | F | G | H | M | P | R | T | Weight (Lbs) |

| E41 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.78 | 1.38 | - | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.88 | 1.38 | - | 1.13 | 0.94 | 0.36 | 12.5 |

| E42 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.78 | 1.58 | - | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.66 | 1.25 | 1.34 | 0.88 | 1.48 | - | 1.13 | 0.94 | 0.36 | 12.5 |

| E43 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.78 | 1.38 | 1.09 | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.88 | 1.38 | 1.09 | 1.13 | 0.94 | 0.36 | 12.5 |

| E44 | |||||||||||||

| 901 | 3.149 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.78 | 1.58 | 1.09 | 1.13 | 0.94 | 0.36 | 12.2 |

| 902 | 2.97 | 0.625 | 5.5 | 0.41 | 1.25 | 1.34 | 0.88 | 1.48 | 1.09 | 1.13 | 0.94 | 0.36 | 12.5 |

| E51 | |||||||||||||

| 907 | 3.17 | 0.625 | 5.5 | 0.66 | 1.31 | 1.44 | 0.72 | 1.69 | - | 1.13 | 0.94 | 0.36 | 12.1 |

| E41 | |||||||||||||

| 5174 | 2.36 | 0.58 | 5.18 | 0.38 | 1.12 | 1.08 | 0.64 | 1.18 | 1 | 1.13 | 0.74 | 0.36 | 11.7 |

Introduction

Welcome to the world of 902 Sugar Mill Chain, a revolutionary product that is set to redefine the sugar industry. Our chain is designed with precision and expertise to deliver unparalleled performance and efficiency in sugar mill operations. In this comprehensive guide, we will explore the various features and benefits of our 902 Sugar Mill Chain, highlighting its unique characteristics and its ability to optimize your sugar production process.

1. Superior Strength and Durability

Our 902 Sugar Mill Chain is engineered with the highest quality materials, ensuring exceptional strength and durability. Through advanced manufacturing techniques and stringent quality control measures, we have created a chain that can withstand the demanding conditions of sugar mill operations, providing long-lasting performance and minimizing downtime.

2. Precise Pitch Control

Pitch control is crucial in sugar mill chains to ensure smooth and efficient operation. With our 902 Sugar Mill Chain, you can expect precise pitch control, thanks to its innovative design and meticulous craftsmanship. This feature enhances the overall performance of your sugar mill by maintaining consistent chain speed and minimizing the risk of chain slippage or breakage.

3. Enhanced Wear Resistance

The abrasive nature of sugar production can cause significant wear and tear on chains. However, our 902 Sugar Mill Chain is specially engineered to resist wear and prolong its service life. With its advanced surface treatment and superior coating, this chain offers exceptional resistance against abrasion, reducing the need for frequent replacements and saving you valuable time and resources.

4. Optimal Load Distribution

The 902 Sugar Mill Chain is designed to distribute the load evenly across its links, ensuring optimum load distribution throughout your sugar mill equipment. This feature minimizes stress concentration and prevents premature chain failure, allowing for continuous and uninterrupted sugar production.

5. Efficient Lubrication System

Proper lubrication is vital for the smooth operation of sugar mill chains. Our 902 Sugar Mill Chain incorporates an efficient lubrication system that facilitates the uniform distribution of lubricants to all critical points, reducing friction and wear. This results in improved chain performance, reduced maintenance costs, and increased overall productivity.

6. Easy Installation and Maintenance

Installing and maintaining our 902 Sugar Mill Chain is a hassle-free process, thanks to its user-friendly design. With clear instructions and minimal components, you can quickly and easily replace or maintain the chain, minimizing downtime and maximizing the efficiency of your sugar mill operations.

Conclusion

In conclusion, the 902 Sugar Mill Chain is a game-changer in the sugar industry, offering superior strength, precise pitch control, enhanced wear resistance, optimal load distribution, efficient lubrication, and easy installation and maintenance. By choosing our 902 Sugar Mill Chain, you are investing in a product that will optimize your sugar mill operations, increase productivity, and ultimately contribute to the growth and success of your business.

Choose Our Malleable Casting Chains

RP Techniek BV is the Dutch sales agent for Ever-power Group. We specialize in providing high-quality malleable cast iron chains, with one of our notable products being the 902 Sugar Mill Chain. Our malleable cast iron chains possess unique selling points that emphasize product quality and exceptional service. We take pride in our strong manufacturing capabilities, ensuring that our chains meet the highest standards.

In addition to our malleable casting chains, we offer a wide range of other casting chains for sale. Our diverse selection ensures that we can cater to various needs and requirements. Whether you require chains for industrial applications or specialized purposes, we have you covered.

To give you a glimpse of our products, please refer to the image below:

Sprockets for Sale

When considering chain options for the 902 Sugar Mill Chain, it's important to choose the right sprocket to ensure optimal performance and durability. Our company offers a wide range of sprockets that are suitable for use with this specific chain, ensuring that you can find the perfect match for your needs.

We understand that every application is unique, which is why we carry various types of sprockets, including those made from different materials and featuring different tooth counts. This ensures that our customers can find the exact sprocket they need to meet their specific requirements.

Our sprockets are manufactured using high-quality materials and state-of-the-art techniques, ensuring that they provide reliable performance and long-lasting durability. We also offer competitive pricing and excellent customer service to ensure that our customers are completely satisfied with their purchase.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...