In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

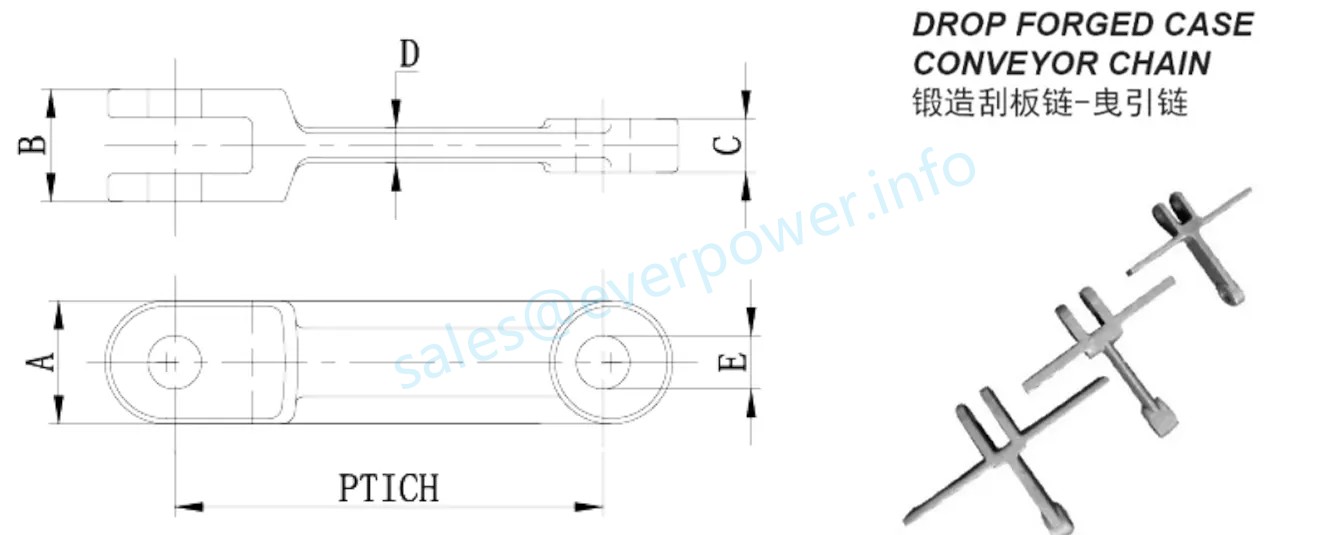

Specifications of 150NA Drop Forged Case Conveyor Chain

| Chain No. | Ultimate Strength | Working Load | Poids | UN | B | C | D | E | Attachment Flights |

| 102HVY | 38,000 Lbs | 6,900 | 0.99 | 1.375¡± | 1.26 | 0.55 | 0.354 | ?0.709 | 10"12"14"16" |

| 17.725 Kg | 3,135 | 0.45 | 35mm | 32 | 14 | 9 | 18 | ||

| 142NA | 73.000 Lbs | 13.000 | 2.45 | 1.97¡± | 1.65 | 0.75 | 0.47 | 0.98 | 11"15"19"25"30" |

| 33.180 Kg | 5.910 | 1.11 | 50mm | 42 | 19 | 12 | 25 | ||

| 142HA | 99.000 Lbs | 18.000 | 3.74 | 1.97" | 2.44 | ?1.14 | 0.63 | 0.98 | 11"15"19"25"30" |

| 45.000 Kg | 8.182 | 1.70 | 50mm | 62 | 29 | 16 | 25 | ||

| 150NA | 67,500 Lbs | 12,272 | 2.64 | 1.93" | 1.42" | 0.59" | 0.51" | 0.98 | 16"19"24"30" |

| 30.612Kg | 5.570 | 1.20 | 49 | 36 | 15 | 13 | 25 | ||

| 260STD | 150,000 Lbs | 27.270 | 14.00 | 2.95" | ?2.76 | ?1.18 | 0.79 | 1.26 | 16"19"24"30" |

| 68.180 Kg | 12,390 | 6.40 | 75mm | 70 | 30 | 20 | 32 |

Introduction

The 150NA Drop Forged Case Conveyor Chain is a high-quality chain designed for heavy-duty industrial applications. With its superior strength and durability, this chain is built to withstand the most demanding operating conditions. Whether used in automotive manufacturing, food processing, or other industrial settings, the 150NA Drop Forged Case Conveyor Chain delivers reliable performance and exceptional longevity.

1. Advanced Forging Technology

Our 150NA Drop Forged Case Conveyor Chain is manufactured using advanced forging technology. This process ensures that each chain link is precisely formed, resulting in a uniform and consistent structure. The forged construction enhances the chain's strength and resistance to wear, allowing it to handle heavy loads with ease.

2. Superior Load Capacity

Designed for heavy-duty applications, the 150NA Drop Forged Case Conveyor Chain offers an impressive load capacity. Its robust construction and precise engineering enable it to carry heavy loads without compromising performance. Whether transporting large components or heavy machinery parts, this chain provides reliable and efficient operation.

3. Corrosion Resistance

The 150NA Drop Forged Case Conveyor Chain is resistant to corrosion, making it suitable for use in challenging environments. The chain's surface is treated with a special coating that protects it from rust, chemicals, and other corrosive substances. This ensures a long lifespan and reduces maintenance requirements, saving both time and money.

4. Smooth and Quiet Operation

Thanks to its precise manufacturing and high-quality materials, the 150NA Drop Forged Case Conveyor Chain operates smoothly and quietly. The chain's design minimizes friction and noise generation, creating a more comfortable working environment. This makes it an ideal choice for applications where noise reduction is a priority.

5. Easy Installation and Maintenance

The 150NA Drop Forged Case Conveyor Chain is designed for easy installation and maintenance. It features convenient attachment points and can be quickly assembled onto existing conveyor systems. Additionally, the chain's robust construction minimizes the need for frequent maintenance, reducing downtime and maximizing productivity.

6. Wide Range of Applications

The versatility of the 150NA Drop Forged Case Conveyor Chain makes it suitable for a wide range of applications. From automotive assembly lines to food processing plants, this chain excels in various industrial settings. Its ability to withstand heavy loads, corrosive environments, and demanding conditions makes it a reliable choice for any industry.

Choose Our Malleable Casting Chains

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands. Our 150NA Drop Forged Case Conveyor Chain is just one example of the quality products we offer. Our malleable cast iron chains are uniquely designed and have a number of advantages including durability, flexibility, and high-quality performance. At RP Techniek BV, we pride ourselves on our commitment to exceptional customer service and our ability to provide our clients with top-of-the-line products.

Our production capabilities are second to none, and we are dedicated to producing the highest quality casting chains available. We offer a wide range of casting chains, including the 150NA Drop Forged Case Conveyor Chain, to meet the diverse needs of our clients.

Choose RP Techniek BV for all your casting chain needs. Contact us today to learn more about our products and services.

Sprockets for Sale

When it comes to the perfect pairing with the 150NA Drop Forged Case Conveyor Chain, our company offers a wide range of suitable sprockets. These sprockets are meticulously designed to ensure optimal performance and longevity.

At our company, we understand the diverse needs of our customers. That is why we provide various types of sprockets for sale, catering to different applications and industries. Whether you require standard sprockets, custom-made sprockets, or specialty sprockets, we have got you covered.

Our high-quality sprockets are manufactured using top-grade materials and cutting-edge technology. They are built to withstand heavy loads, resist wear and tear, and deliver consistent performance in even the most demanding environments.

Trust us to provide you with reliable sprockets that meet your specific requirements. Browse our extensive selection and find the perfect sprockets to complement your 150NA Drop Forged Case Conveyor Chain.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...