In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Dimensions of 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine

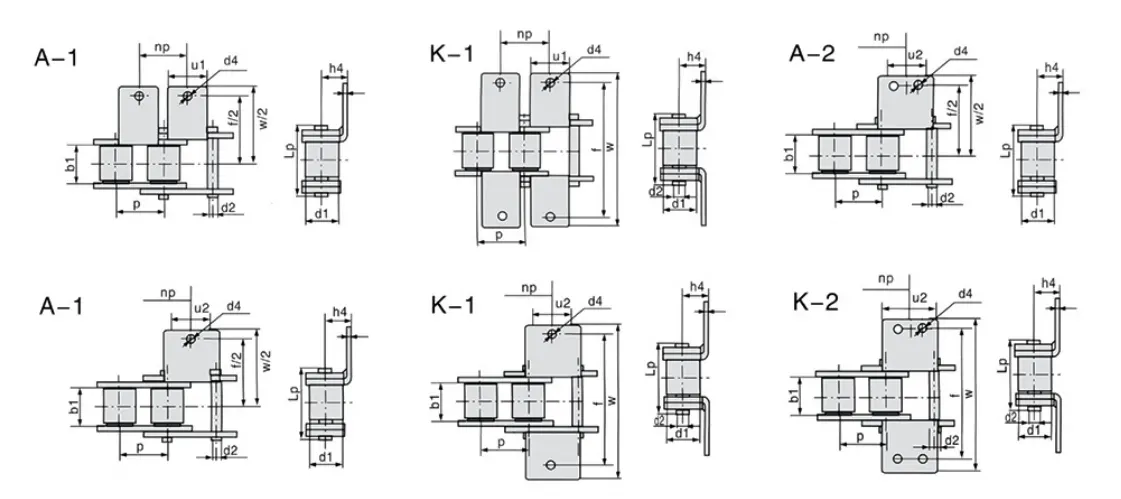

The 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine has the following parameters:

- Pitch: 12.7mm

- Roller diameter: 7.77mm

- Width between inner plates: 7.85mm

- Pin diameter: 3.96mm

- Chain plate height: 15.88mm

- Tensile strength: 8.9kN

- Weight per meter: 1.49kg

| Chain No. |

Pitch | Width between inner plates |

Pin diameter |

Pin length |

Inner plate depth |

|||

| P | b1 | D | d2 | Lp | Lc | h2 | T | |

| min | max | max | max | max | max | max | ||

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 12ASS-K2/A2wJn10.75BSS | 19.05 | 12.57 | 11.91 | 5.94 | 25.6 | 30.1 | 18.08 | 3 |

| Chain No. | h4 | f | g | d4 | w | U1 | U2 | |

| mm | mm | mm | mm | mm | mm | mm | ||

| 12ASS-K2/A2wJn10.75BSS | 10.75 | 41 | 19.05 | 6 | 57.4 | 34.6 | ||

1. Introduction to 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain

The 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain is a highly efficient and durable chain specifically designed for jelly making machines. Made from high-quality stainless steel, this chain offers exceptional strength, corrosion resistance, and longevity.

2. Key Features of 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain

2.1 Enhanced Durability:

The 12ASS-K2/A2wJn10.75BSS chain is constructed using advanced manufacturing techniques, resulting in superior durability. It can withstand heavy loads, high temperatures, and harsh operating conditions, ensuring reliable performance in the jelly making process.

2.2 Corrosion Resistance:

Thanks to its stainless steel composition, this chain exhibits excellent resistance to corrosion caused by moisture, acids, and other chemicals commonly encountered in jelly production. It remains unaffected by the corrosive environment, prolonging its lifespan and minimizing maintenance requirements.

2.3 Smooth Operation:

The chain's design features low friction and optimized internal lubrication channels, ensuring smooth and efficient operation. This reduces energy consumption, enhances productivity, and minimizes wear and tear, contributing to overall cost savings and improved production efficiency.

3. Application of 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain

3.1 Jelly Making Machines:

This chain is specifically designed for use in jelly making machines, where it plays a crucial role in conveying and transferring jelly material throughout the production process. Its reliability, strength, and smooth operation make it an essential component in ensuring consistent and high-quality jelly production.

4. Installation and Maintenance Guidelines

4.1 Proper Installation:

When installing the 12ASS-K2/A2wJn10.75BSS chain, ensure that it is correctly tensioned and aligned with the sprockets. Follow the manufacturer's instructions carefully to achieve optimal performance and prevent premature wear or damage.

4.2 Regular Maintenance:

To ensure the longevity and performance of the chain, regular maintenance is essential. This includes periodic lubrication, inspection for any signs of wear or damage, and prompt replacement of worn-out components. Following the recommended maintenance schedule will maximize the operational lifespan of the chain and contribute to uninterrupted production.

5. Conclusion

The 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain is the ideal choice for jelly making machines. Its superior durability, corrosion resistance, and smooth operation ensure reliable and efficient performance in jelly production processes. By investing in this high-quality chain, manufacturers can enhance productivity, reduce maintenance costs, and deliver consistent, high-quality jelly products to their customers.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, the sales agent of Ever-power Group in the Netherlands, takes pride in offering high-quality stainless steel roller chains. Our commitment to excellence is demonstrated through our product range, including the 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine.

Our unique selling points lie in the exceptional quality and reliability of our stainless steel roller chains. Crafted with precision, these chains are designed to withstand the most demanding environments and provide smooth and efficient operation.

At RP Techniek BV, we understand the importance of exceptional customer service. Our team of experts is dedicated to providing personalized assistance and guidance, ensuring that our customers find the perfect stainless steel roller chains for their specific needs.

Furthermore, we take pride in our strong manufacturing capabilities. Our state-of-the-art facilities and advanced technology enable us to produce stainless steel roller chains that meet the highest industry standards.

In addition to the 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine, we offer a wide range of other stainless steel roller chains for various applications. Our diverse product line ensures that customers can find the perfect chain for their specific requirements.

Discover the reliability and performance of our stainless steel roller chains. Choose RP Techniek BV and experience the difference in quality and service.

Sprockets for Sale

When it comes to finding the perfect match for the 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine, our company offers a wide range of sprockets to meet your needs.

Our sprockets are designed with precision and durability in mind, ensuring smooth and efficient operation of your machinery. Whether you require standard or custom-made sprockets, we have the solution for you.

With our extensive inventory, we provide various types of sprockets, including those made from different materials, such as stainless steel, carbon steel, and plastic. Our sprockets come in different sizes and tooth configurations to accommodate different chain pitches and load requirements.

At our company, we understand the importance of reliability and performance in your operations. That's why we offer high-quality sprockets that are built to last. Our experienced team is dedicated to providing you with the right sprockets that will enhance the efficiency and productivity of your jelly making machine.

Take a look at the image below to get a glimpse of our sprocket selection:

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...