In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

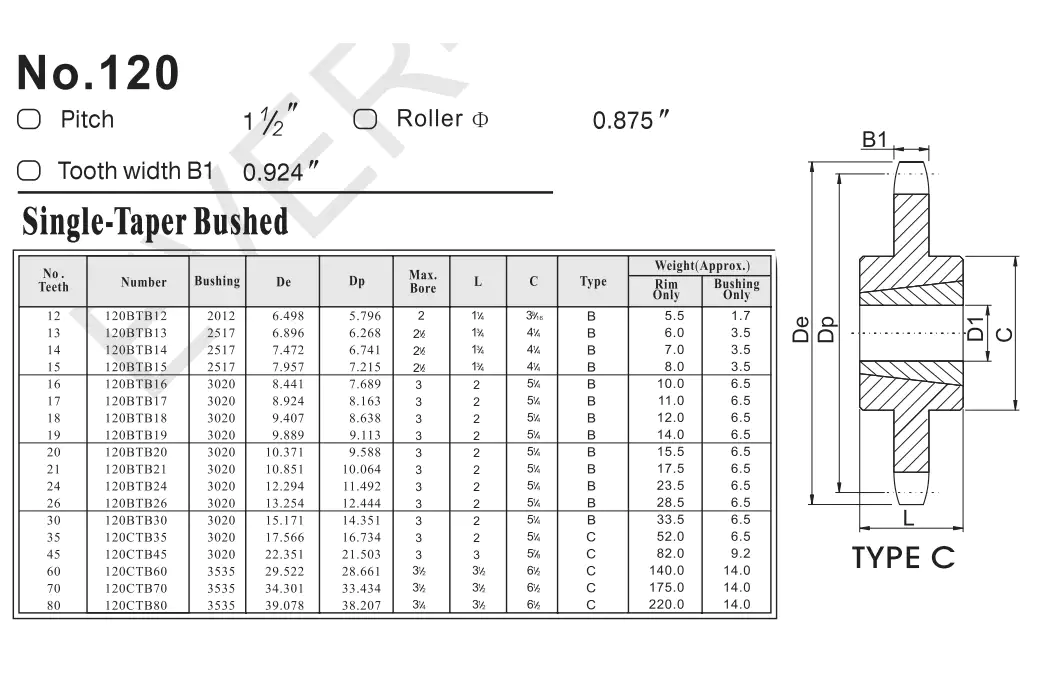

#120 1 1/2″ Taper Bore Sprocket

The #120 1 1/2″ Taper Bore Sprocket is engineered for optimal power transmission and durability. Designed to fit seamlessly with various machinery, it ensures efficient operation in demanding environments. Its robust construction and precision taper bore design provide excellent alignment and stability, making it an ideal choice for industrial applications.

#120 1 1/2" Taper Bore Sprocket Specifications

The Taper Bore Sprocket No.120 American Standard is a specialized sprocket that employs a taper lock design, which greatly simplifies both the installation and removal processes. It is widely utilized in power transmission systems, where it plays a crucial role in transferring rotational motion between different shafts. This design not only enhances efficiency but also ensures reliability in various mechanical applications.

Characteristics and Functions of Taper Lock Sprocket

- Easy Installation: The taper lock design allows for quick and efficient installation of the sprocket onto the shaft, reducing downtime during setup.

- High Precision Positioning: Taper lock sprockets deliver accurate positioning on the shaft, which is vital for ensuring smooth and effective power transmission across various systems.

- Wide Applicability: These sprockets are versatile and can be utilized in numerous applications across different sectors, making them a valuable asset.

- Reliability: Known for their reliability, taper lock sprockets boast a long service life, which is crucial for minimizing operational disruptions.

- Low Maintenance Cost: The straightforward design of taper lock sprockets reduces maintenance needs, thus lowering associated costs and enhancing overall efficiency.

Taper Lock Sprocket Installation and Removal Process

The process for installing and removing a taper lock sprocket involves several systematic steps to ensure proper setup:

- Prepare Tools and Materials: Collect all necessary tools and materials that will be required for the installation process to ensure a smooth operation.

- Clean Shaft and Sprocket Surface: Thoroughly clean both the shaft and the sprocket surface to eliminate any debris or contaminants that could interfere with the installation.

- Place Taper Lock Bushing: Insert the taper lock bushing into the sprocket bore, making sure that it fits properly to avoid any issues during operation.

- Install Sprocket: Carefully slide the sprocket onto the shaft, ensuring it aligns correctly with the taper lock bushing for optimal engagement.

- Tighten Locking Nut: Utilize the appropriate tool to securely tighten the locking nut, effectively fastening the sprocket to the shaft to prevent slippage.

Manufacturing Process of Taper Lock Sprockets

The manufacturing process for taper lock sprockets involves a series of critical steps designed to ensure quality and precision:

- Raw Material Preparation: Begin by selecting high-quality materials specifically suited for producing durable sprockets.

- Cutting: Accurately cut the raw materials to the required shapes and sizes according to specifications.

- Forging or Casting: Employ either forging or casting methods to form the sprocket into its desired structure.

- Machining: Apply precision machining techniques to refine and finish the sprocket, ensuring it meets strict quality standards.

- Teeth Rolling: Utilize a rolling process to create the necessary teeth on the sprocket, which are critical for its function.

- Heat Treatment: Implement heat treatment processes to enhance the hardness and overall durability of the sprocket.

- Traitement de surface : Conduct surface treatment, such as coating or plating, to protect the sprocket against corrosion and wear.

- Quality Inspection: Perform thorough quality inspections to confirm that each sprocket meets the established standards for performance and safety.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the Dutch sales agent for Ever-power Group, a prominent manufacturer within the power transmission sector. We provide an extensive range of high-quality sprockets, including the #120 1 1/2" Taper Bore Sprocket, engineered for optimal performance across various applications. Our products are designed for durability and reliability, ensuring smooth operation in all types of machinery.

Beyond our standard offerings, RP Techniek BV specializes in custom solutions. We can produce non-standard sprockets tailored to meet specific customer requirements. Our clients are encouraged to present their designs or samples for personalized customization, ensuring that we meet their unique needs.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...