In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

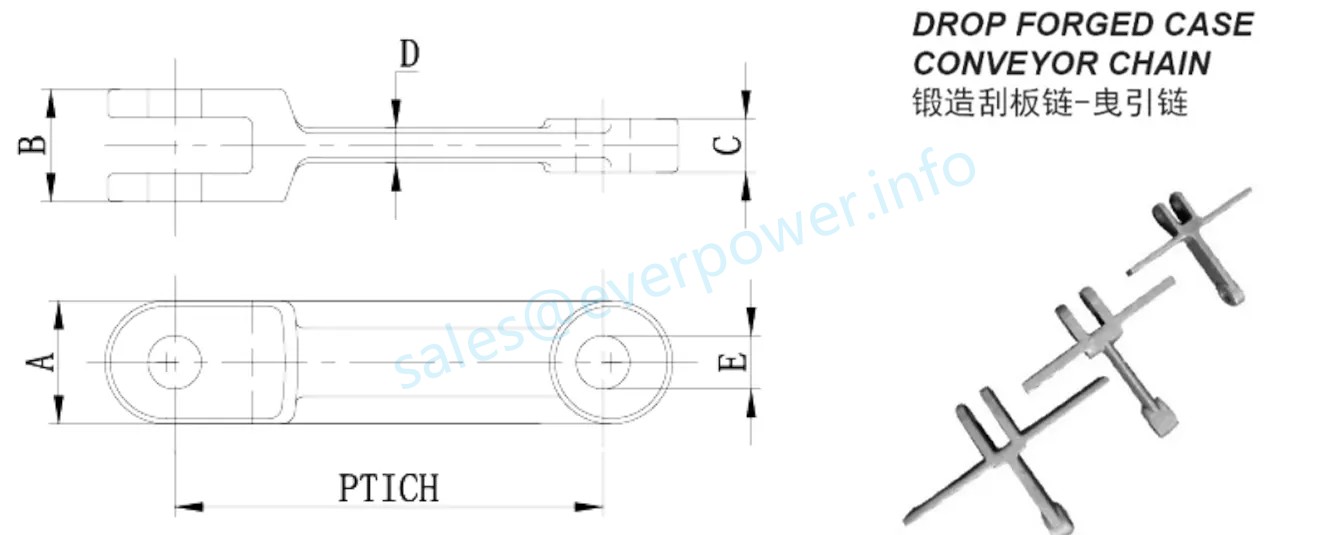

Specifications of 102HVY Drop Forged Case Conveyor Chain

Below are the parameters of this chain:

| Chain No. | Ultimate Strength | Working Load | Poids | UN | B | C | D | E | Attachment Flights |

| 102HVY | 38,000 Lbs | 6,900 | 0.99 | 1.375¡± | 1.26 | 0.55 | 0.354 | ?0.709 | 10"12"14"16" |

| 17.725 Kg | 3,135 | 0.45 | 35mm | 32 | 14 | 9 | 18 | ||

| 142NA | 73.000 Lbs | 13.000 | 2.45 | 1.97¡± | 1.65 | 0.75 | 0.47 | 0.98 | 11"15"19"25"30" |

| 33.180 Kg | 5.910 | 1.11 | 50mm | 42 | 19 | 12 | 25 | ||

| 142HA | 99.000 Lbs | 18.000 | 3.74 | 1.97" | 2.44 | ?1.14 | 0.63 | 0.98 | 11"15"19"25"30" |

| 45.000 Kg | 8.182 | 1.70 | 50mm | 62 | 29 | 16 | 25 | ||

| 150NA | 67,500 Lbs | 12,272 | 2.64 | 1.93" | 1.42" | 0.59" | 0.51" | 0.98 | 16"19"24"30" |

| 30.612Kg | 5.570 | 1.20 | 49 | 36 | 15 | 13 | 25 | ||

| 260STD | 150,000 Lbs | 27.270 | 14.00 | 2.95" | ?2.76 | ?1.18 | 0.79 | 1.26 | 16"19"24"30" |

| 68.180 Kg | 12,390 | 6.40 | 75mm | 70 | 30 | 20 | 32 |

Overview

The 102HVY Drop Forged Case Conveyor Chain is a heavy-duty chain designed for industrial applications. It is used in material handling systems to move heavy loads along a conveyor line. The chain is made of high-quality materials and is engineered to withstand extreme conditions.

Construction

The 102HVY chain is constructed using drop forging technology. This process involves heating the metal to a high temperature and then forging it into shape using a drop hammer. This results in a stronger, more durable chain that can handle heavy loads and withstand harsh environments.

Features

- Heavy-duty construction

- Drop forged for maximum strength

- Designed for use in harsh environments

- Available in a variety of sizes

- Easy to install and maintain

Applications

The 102HVY chain is commonly used in a range of industrial applications, including:

- Automotive manufacturing

- Steel production

- Mining

- Agriculture

- Construction

Maintenance

Maintaining the 102HVY chain is important to ensure its longevity and proper functioning. Regular lubrication is recommended to reduce wear and prevent corrosion. The chain should also be inspected periodically for signs of damage or wear. If any issues are found, the chain should be replaced immediately.

Conclusion

The 102HVY Drop Forged Case Conveyor Chain is an essential component in material handling systems for heavy-duty industrial applications. Its superior strength, durability, and ease of maintenance make it an ideal choice for a range of industries. Invest in the 102HVY chain for reliable and efficient conveyor operation.

Choose Our Malleable Casting Chains

RP Techniek BV is the sales representative of Ever-power Group in the Netherlands. Our malleable cast iron chains, including the 102HVY Drop Forged Case Conveyor Chain, are a unique selling point that sets us apart from other companies. We take pride in our product quality and exceptional customer service, as well as our strong manufacturing capabilities.

Our malleable casting chains are designed to offer durability and reliability in even the most challenging industrial settings. They are made using high-quality materials and state-of-the-art manufacturing processes, ensuring that they can withstand heavy loads and harsh working conditions.

In addition to our malleable casting chains, we offer a range of other casting chains to meet the needs of our customers. Our extensive selection includes everything from conveyor chains and stainless steel chains to agricultural chains and engineering chains.

At RP Techniek BV, we are committed to providing our customers with the best possible products and services. Whether you need help selecting the right chain for your application, or require assistance with installation or maintenance, our team of experts is here to help.

Sprockets for Sale

When it comes to finding the perfect match for your 102HVY drop forged case conveyor chain, choosing the right sprocket is crucial. At our company, we offer a wide variety of sprockets to ensure that you can find the best fit for your specific needs.

Our sprockets come in different sizes and tooth counts, allowing you to customize your conveyor system to your exact specifications. Made from high-quality materials, our sprockets are durable and designed to withstand heavy loads and intense usage.

Whether you need a standard sprocket or a custom design, we have you covered. Our team of experienced professionals can help you find the perfect sprocket for your conveyor system, ensuring optimal performance and efficiency.

Don't settle for anything less than the best. Contact us today to learn more about our selection of sprockets for sale and how we can help you find the perfect match for your conveyor system.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...