In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

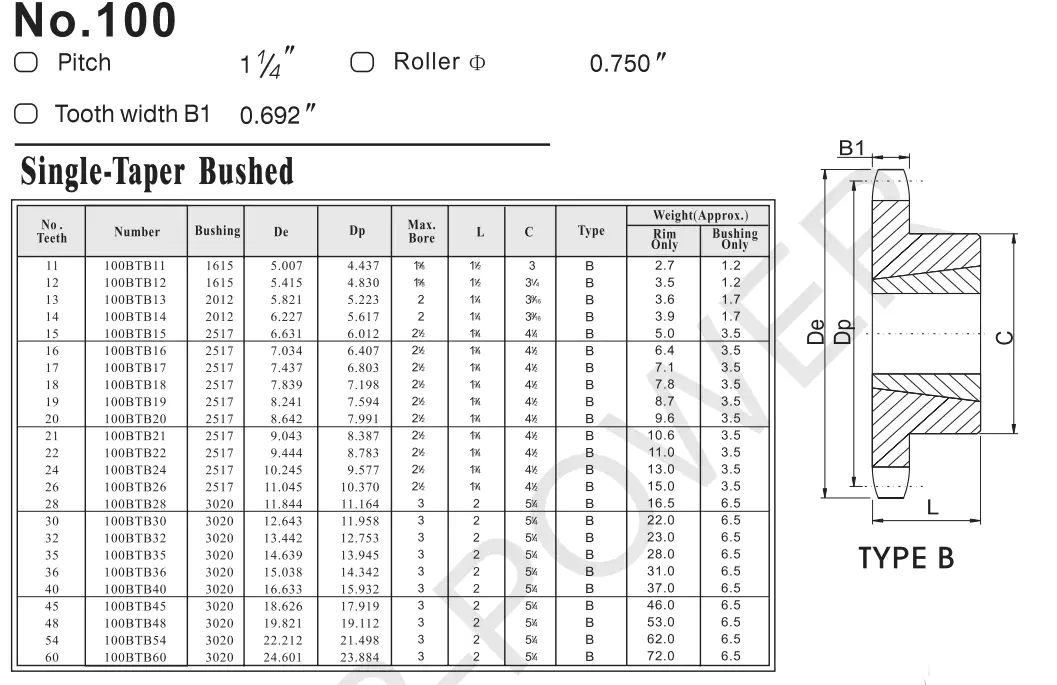

#100 1 1/4″ Taper Bore Sprocket

The #100 1 1/4″ Taper Bore Sprocket is an essential component designed for efficient power transmission in various machinery. Engineered for durability and precision, it features a tapered bore for easy installation on shafts. Ideal for heavy-duty applications, this sprocket ensures optimal performance and reliability in demanding environments.

#100 1 1/4" Taper Bore Sprocket Specifications

The Taper Bore Sprocket No.100 American Standard is a crucial element commonly employed in power transmission setups. It features a specially designed tapered bore, which allows for effective mounting onto a shaft using a taper lock bushing. This design not only facilitates installation but also ensures a stable connection during operation, making it a reliable choice for various mechanical applications.

A taper bore sprocket is an essential mechanical component utilized in power transmission systems, serving the purpose of conveying rotary motion from one shaft to another. This device is characterized by a toothed wheel that possesses a tapered bore, paired with a hub that matches this taper. The hub is securely mounted onto the shaft through the use of a taper lock bushing, ensuring a precise and stable connection that enhances the overall performance of the machinery.

Features and Functions

- Easy Installation: The design of the taper bore sprocket emphasizes user-friendly installation. The accompanying taper lock bushing allows for quick and straightforward mounting onto the shaft, significantly reducing installation time.

- High Precision Positioning: The taper lock mechanism plays a vital role in ensuring the accurate positioning of the sprocket on the shaft. This precision minimizes any potential misalignment, thereby enhancing the overall performance and efficiency of the system.

- Wide Applicability: Taper bore sprockets are extensively utilized across various industries, owing to their versatility and compatibility with a range of different shaft sizes, making them a popular choice in mechanical design.

- Reliability: The taper lock connection offers a dependable and secure means of power transmission. This significantly decreases the likelihood of slippage, leading to efficient and uninterrupted operation of the equipment.

- Low Maintenance Cost: Taper bore sprockets are designed to require minimal maintenance, which in turn helps to lower downtime and associated maintenance costs, making them a cost-effective solution.

Installation and Removal Process

- Prepare Tools and Materials: Before starting, gather all necessary tools and materials, such as the taper lock bushing, wrenches, and cleaning supplies to ensure a smooth installation process.

- Clean Shaft and Sprocket Surface: It is important to thoroughly clean both the shaft and the sprocket surface. This step ensures that the contact area is smooth and free of contaminants, which is crucial for a secure fit.

- Place Taper Lock Bushing: Carefully install the taper lock bushing into the sprocket hub. Make sure that it fits tightly and securely to prevent any potential issues during operation.

- Install Sprocket: Next, slide the sprocket onto the shaft, ensuring proper alignment with the taper lock bushing for an effective connection.

- Tighten Locking Nut: Finally, use the appropriate tools to tighten the locking nut. This step is essential as it secures the sprocket firmly in place, ensuring it operates efficiently.

Manufacturing Process

- Raw Material Preparation: The first step involves selecting high-quality materials that are appropriate for the specific application of the sprocket, ensuring durability and functionality.

- Material Cutting: The selected raw materials are then cut into the desired shape and size, which is critical for the subsequent manufacturing stages.

- Forging or Casting: The sprocket blank is formed through either forging or casting processes, depending on the material properties and design specifications needed for the final product.

- Machining: Precision machining techniques are employed to create the tooth profile and other critical features of the sprocket, ensuring that it meets the required specifications.

- Teeth Rolling: Rolling the teeth of the sprocket is performed to enhance their strength and durability, contributing to the overall performance of the component.

- Heat Treatment: Heat treatment is applied to the sprocket to increase its hardness and wear resistance, which is essential for longevity in demanding applications.

- Traitement de surface : Various surface coatings or treatments are applied to improve resistance to corrosion and enhance the aesthetic appeal of the sprocket.

- Quality Inspection: Finally, rigorous quality inspections are conducted to ensure that the sprocket meets all specified standards and requirements, guaranteeing its reliability in use.

Sprockets Supplier in the Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, offering a wide variety of high-quality mechanical components. Among the products available is the #100 1 1/4" Taper Bore Sprocket, which is engineered for durability and high efficiency in numerous industrial applications. Our sprockets are designed to comply with strict quality standards, ensuring optimal performance in any machinery.

In addition to standard sprockets, we also provide custom solutions tailored to fulfill specific customer requirements. If you require a unique design or specialized dimensions, our expert team is ready to assist you. We encourage customers to share their drawings or samples with us to explore the best custom manufacturing options that fit their needs.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...