EPRV series small worm gearboxes are often used in various industrial applications due to their reliable performance, versatility, and cost-effectiveness. However, to ensure optimal performance and longevity, it is essential to evaluate and monitor the gearboxes regularly. In this article, we will cover the key aspects of evaluating the performance of EPRV series small worm gearboxes.

Introduction

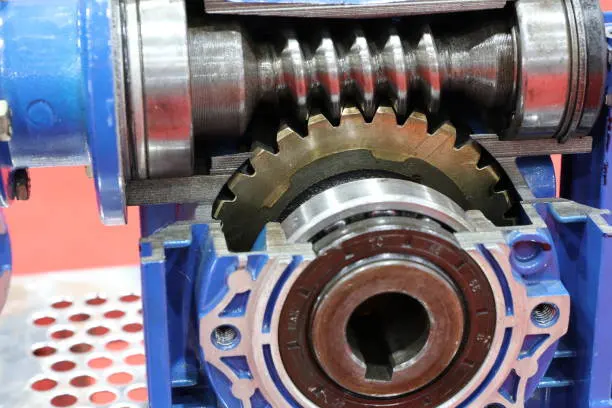

Before we delve into the details of evaluating the performance of EPRV series small worm gearboxes, let us first introduce these gearboxes and their applications. EPRV series small worm gearboxes are compact, efficient, and durable power transmission components that can be used in a wide range of mechanical systems. They consist of a worm gear and a worm wheel, where the worm (a screw-like component) engages with the teeth of the worm wheel (a flat disc with teeth around its circumference).

The input shaft of the gearbox is connected to an electric motor or other power source, which drives the worm. The rotation of the worm then causes the worm wheel to rotate, resulting in a speed reduction between the input and output shafts of the gearbox. EPRV series small worm gearboxes are commonly used in applications such as conveyors, packaging machines, mixers, and other industrial machinery.

Performance Evaluation

Operating Temperature

One of the critical factors that affect the performance and longevity of EPRV series small worm gearboxes is the operating temperature. Excessive heat can cause premature wear and damage to the gearbox components, leading to reduced performance and potentially catastrophic failure. Therefore, it is important to monitor the operating temperature of the gearbox and ensure that it stays within the recommended range.

Load Capacity

Another important factor to consider when evaluating the performance of EPRV series small worm gearboxes is their load capacity. The load capacity of a gearbox refers to the maximum amount of torque that it can transmit without failure. Exceeding the load capacity can cause damage to the gearbox, leading to reduced performance and potential safety hazards. Therefore, it is crucial to ensure that the gearbox is not overloaded and that the load remains within the recommended range.

Gearbox Efficiency

The efficiency of a gearbox refers to the ratio of output power to input power. A higher efficiency means that less power is lost due to friction and other losses, resulting in more efficient power transmission and reduced energy consumption. Therefore, it is essential to evaluate the efficiency of EPRV series small worm gearboxes and ensure that it meets the required specifications.

Gearbox Noise and Vibration

Noise and vibration are common issues in mechanical systems and can be indicative of problems with the gearbox components. Excessive noise and vibration can cause discomfort to operators and potentially damage the gearbox. Therefore, it is important to monitor the gearbox for noise and vibration and diagnose and address any issues that arise.

Conclusion

Evaluating the performance of EPRV series small worm gearboxes is crucial to ensure their optimal operation and longevity. By monitoring the operating temperature, load capacity, efficiency, noise, and vibration of the gearbox, operators can identify and address any issues that may arise. Performing regular maintenance and inspections can also help prevent premature wear and damage to the gearbox components.

Moteurs électriques à vendre

Electric motors and small worm gearboxes are complementary components in many mechanical systems. The gearbox provides speed reduction and torque multiplication, while the electric motor provides the power to drive the gearbox. Therefore, it is essential to select the right electric motor for the gearbox and vice versa to ensure optimal performance.

At RP Techniek BV, we offer a wide range of electric motors for our EPRV series small worm gearboxes. Our motors are designed to provide reliable and efficient power transmission and are compatible with our gearboxes. We also offer customized solutions to meet the specific needs of our customers.

If you are interested in exploring our electric motors and small worm gearboxes, please contact us for more information. We would be happy to assist you with your power transmission needs.

À propos de nous

RP Techniek BV is the Netherlands sales agent of the Ever-power group, a comprehensive transmission equipment manufacturer. With over 25 years of experience in the design, production, manufacture, and sales of gearboxes, we have served customers in Europe, America, Africa, Asia, and other regions and have won the praise of the market.

We pride ourselves on providing the highest quality products, the most competitive prices, and the best customer service in the industry. Our gearboxes are widely used in various industrial applications, including the equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and more.

Our mission is to provide our customers with high-quality, energy-efficient, and cost-effective transmission solutions that meet their specific needs. We achieve this by investing in the latest technology, employing industry professionals and technicians, and using standardized production management methods to ensure the highest quality products.

Q&A

Q: What is the recommended operating temperature range for EPRV series small worm gearboxes?

A: The recommended operating temperature range for EPRV series small worm gearboxes is typically between -10¡ãC and 80¡ãC. Exceeding this range can cause premature wear and damage to the gearbox components.

Q: How can I monitor the load capacity of the gearbox?

A: The load capacity of the gearbox can be monitored by measuring the torque applied to the output shaft and comparing it to the maximum torque specified in the gearbox’s documentation.

Q: What is the typical efficiency range of EPRV series small worm gearboxes?

A: The typical efficiency range of EPRV series small worm gearboxes is between 50% and 80%, depending on the specific model and operating conditions.

Q: How can I diagnose noise and vibration issues in the gearbox?

A: Noise and vibration issues in the gearbox can be diagnosed by performing a visual inspection of the gearbox components, measuring the vibration levels of the gearbox, and using diagnostic tools such as a stethoscope or vibration analyzer.

Q: What is the warranty period for EPRV series small worm gearboxes?

A: The warranty period for EPRV series small worm gearboxes varies depending on the manufacturer and model. Typically, the warranty period is between one and three years.

Edité par : Zqq.