What Are the Effects of Misalignment on EPRV Series Small Worm Gearboxes?

Introduction:

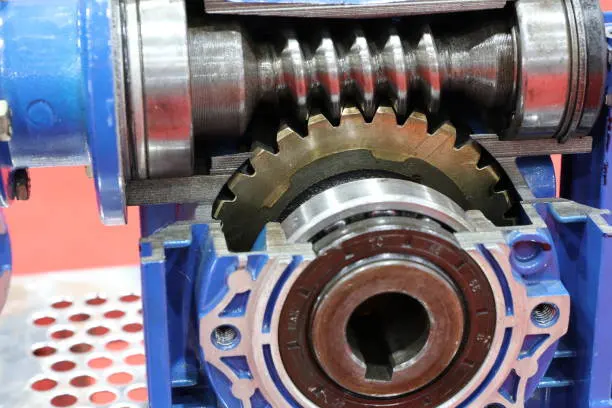

The EPRV series small worm gearboxes are a vital component in various industrial applications. However, it is important to understand the effects of misalignment on these gearboxes to ensure their optimal performance and longevity. In this article, we will explore the different aspects of misalignment and its consequences on EPRV series small worm gearboxes.

1. The Significance of Proper Alignment

Alignment plays a crucial role in the performance of EPRV series small worm gearboxes. Proper alignment ensures the efficient transfer of power, reduces wear and tear, and extends the lifespan of the gearbox. Let’s delve deeper into the effects of misalignment:

1.1 Angular Misalignment

Angular misalignment occurs when the input and output shafts are not parallel. This type of misalignment can result in:

- Increased friction and heat generation

- Premature bearing failure

- Reduced efficiency

To prevent angular misalignment, it is essential to ensure accurate alignment during installation and periodic maintenance.

1.2 Axial Misalignment

Axial misalignment refers to the displacement of the input and output shafts along the gearbox’s axis. The effects of axial misalignment include:

- Uneven distribution of load

- Excessive bearing stress

- Increased vibration and noise levels

Proper alignment and regular inspections can help mitigate these issues.

2. Techniques for Alignment

Aligning EPRV series small worm gearboxes requires precision and expertise. Here are some common techniques used for alignment:

2.1 Laser Alignment

Laser alignment is a highly accurate method that utilizes laser technology to measure and correct misalignment. It offers advantages such as:

- Quick and precise alignment

- Real-time monitoring

- Reduced downtime

Laser alignment should be performed by trained professionals to ensure optimal results.

2.2 Dial Indicator Alignment

Dial indicator alignment involves using dial indicators to measure the misalignment and make adjustments accordingly. It is a cost-effective method suitable for less critical applications.

3. Importance of Regular Maintenance

Maintaining EPRV series small worm gearboxes is essential to prevent misalignment-related issues. Regular maintenance activities include:

- Lubrication of gears and bearings

- Tightening of bolts and fasteners

- Inspection of alignment

By following a comprehensive maintenance schedule, the risk of misalignment can be significantly minimized.

Moteurs électriques à vendre

The relationship between gearboxes and electric motors is symbiotic. Electric motors provide the necessary power to drive the EPRV series small worm gearboxes, enabling efficient transmission of rotational motion. The importance of this partnership cannot be overstated. Our company, RP Techniek BV, not only specializes in EPRV series small worm gearboxes but also offers a wide range of electric motors for sale.

À propos de nous

RP Techniek BV is the official sales representative of Ever-power Group in the Netherlands. We pride ourselves on being a comprehensive transmission equipment manufacturer with over 25 years of experience. Our gearboxes are trusted by customers worldwide, particularly in Europe and America, due to our commitment to providing top-quality products, competitive pricing, and exceptional customer service. We have a state-of-the-art production facility equipped with advanced machinery and a dedicated team of industry professionals and technicians. Our gearboxes find applications in various industries, including equipment, food, car washing, packaging, transmission, automation, and solar energy. We encourage you to explore our products and contact us for all your gearbox needs.

Q&A:

Q1: What are the key factors to consider during the installation of EPRV series small worm gearboxes?

A1: Proper alignment, lubrication, and regular maintenance are crucial for the successful installation of EPRV series small worm gearboxes.

Q2: How does angular misalignment impact the performance of small worm gearboxes?

A2: Angular misalignment can lead to increased friction, premature bearing failure, and reduced efficiency in small worm gearboxes.

Q3: What are the advantages of laser alignment over other alignment techniques?

A3: Laser alignment offers quick and precise alignment, real-time monitoring, and reduced downtime compared to other alignment methods.

Q4: Why is regular maintenance important for EPRV series small worm gearboxes?

A4: Regular maintenance ensures proper lubrication, tightness of components, and early detection of misalignment issues, thereby prolonging the life of the gearboxes.

Q5: Can EPRV series small worm gearboxes be used in the solar energy industry?

A5: Yes, EPRV series small worm gearboxes are widely used in the solar energy industry due to their reliability and efficiency in transmitting power.

Edité par : Zqq.