Introduction

Pharmaceutical packaging equipment plays a crucial role in ensuring the safety and integrity of medical products. One essential component of such equipment is the worm gearbox, which offers precise control and efficient power transmission in the packaging process. This article will delve into the intricacies of worm gearboxes, specifically focusing on their application in pharmaceutical packaging equipment in Utrecht.

The Importance of Worm Gearboxes for Pharmaceutical Packaging Equipment

1. Ensuring Reliable Power Transmission

2. Handling High Torque Loads

3. Enhancing Efficiency and Precision

4. Minimizing Noise and Vibration

5. Facilitating Speed Regulation

6. Enabling Compact Design

7. Withstanding Harsh Environments

8. Improving Reliability and Durability

9. Supporting Hygienic Packaging Standards

10. Meeting Regulatory Requirements

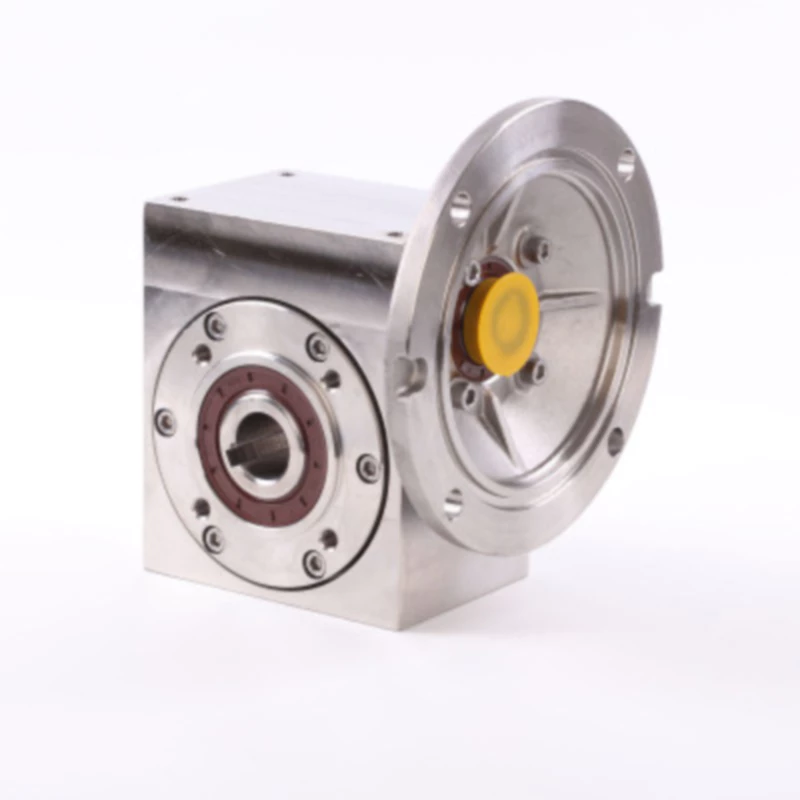

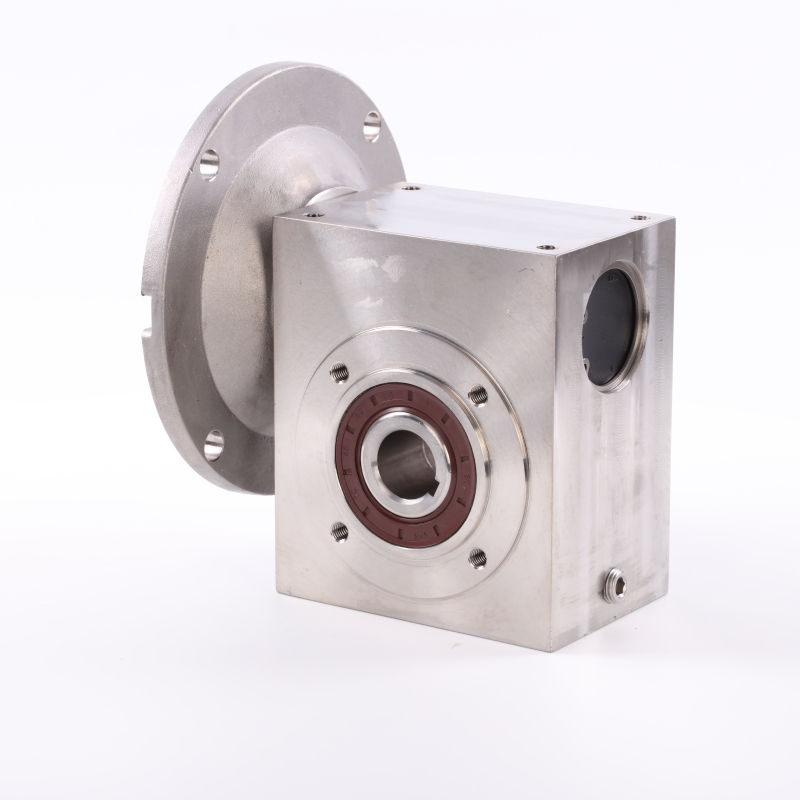

The Anatomy of a Worm Gearbox for Pharmaceutical Packaging Equipment

A worm gearbox consists of several key components:

1. Worm Shaft: The input component that transmits rotational motion to the worm wheel.

2. Worm Wheel: The output component that meshes with the worm shaft, converting the rotational motion into linear motion.

3. Gear Housing: The protective casing that houses the worm shaft and worm wheel, providing support and stability.

4. Bearings: Bearings are essential for reducing friction and ensuring smooth operation.

5. Lubrication System: Proper lubrication is crucial for minimizing wear and extending the lifespan of the gearbox.

The Installation Process of Stainless Steel Worm Gearbox and Motor

1. Prepare the mounting surface and ensure it is clean and level.

2. Align the gearbox and motor, ensuring proper alignment of the input and output shafts.

3. Securely fasten the gearbox and motor to the mounting surface using appropriate bolts and brackets.

4. Connect the motor to the power supply, following the manufacturer’s instructions.

5. Verify the proper functioning of the gearbox and motor by conducting thorough testing.

Common Issues and Troubleshooting

| Problem | Solution |

|---|---|

| Excessive Noise | Check for misalignment, worn gears, or insufficient lubrication. Address the root cause and replace any damaged components. |

| Overheating | Inspect the ventilation system, ensure proper lubrication, and reduce the load if necessary. Consider using heat dissipation mechanisms. |

| Leakage | Check for damaged seals or gaskets. Replace them as needed and inspect the lubrication system for any leaks. |

| Inconsistent Performance | Verify the input power, check for worn gears or misalignment, and ensure proper lubrication. Adjust or replace components accordingly. |

| Severe Wear | Inspect the lubrication system, check for misalignment, and use appropriate lubricants. Replace worn gears or bearings as necessary. |

Stainless Steel Geared Motors for Sale

The relationship between gearboxes and motors is symbiotic. In the case of pharmaceutical packaging equipment, stainless steel geared motors play a vital role. These motors, specifically designed to work in conjunction with worm gearboxes, provide the necessary power and control to drive the packaging process.

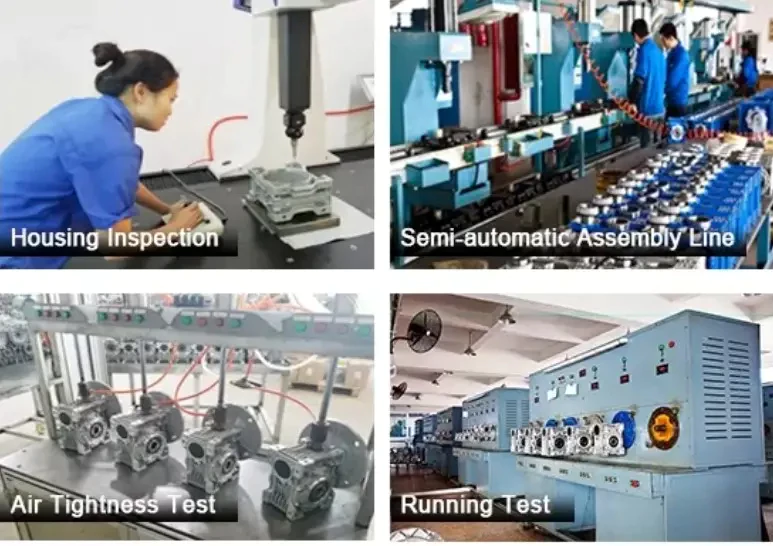

À propos de nous

RP Techniek BV is the Netherlands sales agent for the Ever-power Group, a renowned provider of high-quality industrial equipment. We specialize in stainless steel worm gearboxes and have earned a reputable position in the market, serving clients across Europe and the Americas. Our commitment to delivering superior products, excellent service, and competitive prices sets us apart from the competition.

Explore our range of worm gearboxes and contact us today to experience the difference!

Q&A

Q: Can the worm gearbox be used in other industries apart from pharmaceutical packaging?

A: Absolutely! Worm gearboxes find applications in various industries such as food processing, automotive, and material handling.

Q: Are stainless steel worm gearboxes resistant to corrosion?

A: Yes, stainless steel worm gearboxes are highly resistant to corrosion, making them ideal for environments with strict hygiene requirements.

Q: How often should the lubrication of a worm gearbox be checked?

A: Regular lubrication checks are recommended, and the frequency depends on factors such as operating conditions and usage intensity.

Q: Can the gearbox and motor be replaced separately?

A: Yes, in many cases, the gearbox and motor can be replaced separately, allowing for easier maintenance and cost-effective repairs.

Q: Is it possible to customize worm gearboxes for specific packaging equipment requirements?

A: Yes, manufacturers often offer customization options to tailor worm gearboxes to specific machinery and application needs.

Edité par : Zqq.