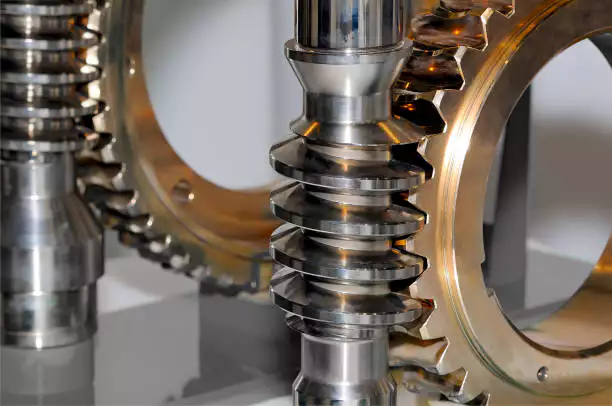

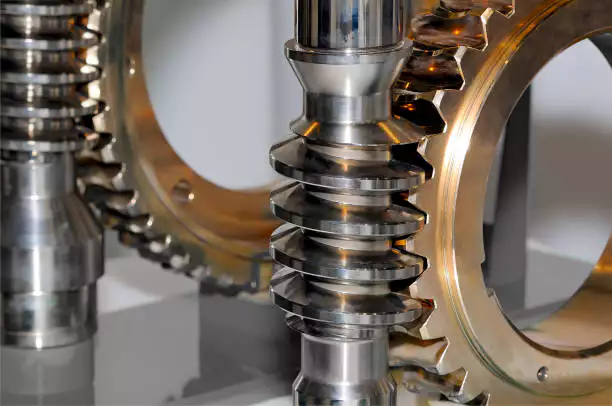

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Rolling Mills

The worm gear in rolling mills is a crucial component designed to provide efficient torque conversion and reduce speed in various metal forming processes. In rolling mill machinery, this specialized gear enables precise control of the rolling process, ensuring optimal performance and reliability. Worm gear for metal rolling processes is essential for achieving high efficiency in heavy-duty worm gear for rolling mills, which withstands the demands of steel production. The worm gear in steel rolling systems ensures smooth operations and enhances productivity in industrial applications.

Specifications of Worm Gear in Rolling Mills

| Spécification | Details |

|---|---|

| Gear Ratio | 10:1 |

| Matériel | Alloy Steel |

| Load Capacity | 2000 Nm |

| Efficiency | 90% |

| Mounting Type | Horizontal |

| Operating Temperature | -20°C to 100°C |

Why Worm Gears are Suitable for Worm Gear in Rolling Mills

- Worm gears provide high torque and precise speed reduction, essential in worm gear in rolling mill machinery.

- These gears are ideal for rolling mill worm gear applications due to their compact design and efficiency.

- They ensure smooth operation in worm gear for metal rolling processes, minimizing wear and tear.

- Heavy-duty worm gear for rolling mills supports demanding industrial conditions and heavy loads.

- Integrating worm gear in steel rolling systems enhances reliability and performance in metalworking.

How Worm Gears Work in Rolling Mills

Worm gears play a crucial role in rolling mills, enabling precise control and efficient power transmission. In rolling mill machinery, the worm gear's unique design allows it to handle heavy loads and provide high torque, making it ideal for metal rolling processes. The compact nature of the worm gear in rolling mills ensures that space is effectively utilized, which is essential in steel rolling systems. With applications ranging from heavy-duty worm gears for rolling mills to specialized setups for various metalworking tasks, these gears facilitate smooth operation and enhance productivity. The integration of worm gear in rolling mill machinery contributes significantly to the overall efficiency and reliability of rolling mill operations.

Manufacturing Process of Worm Gears in Rolling Mills

- Design and Engineering: The manufacturing process of worm gears in rolling mills begins with detailed design and engineering. This phase involves creating precise specifications for the worm gear in rolling mill machinery, ensuring it meets the specific demands of heavy-duty applications. Engineers utilize advanced software to simulate the performance of the worm gear for metal rolling processes, focusing on durability and efficiency in steel rolling systems to optimize the overall design.

- Material Selection: The next step is the careful selection of materials. High-strength alloys are chosen for their ability to withstand the immense pressures encountered in rolling mill worm gear applications. The selection process considers factors like wear resistance and tensile strength, which are critical for heavy-duty worm gears in rolling mills. These materials ensure longevity and reliable performance in harsh operating conditions.

- Manufacturing Techniques: Various manufacturing techniques are employed to produce worm gears in rolling mills, including casting, forging, and machining. Each method offers distinct advantages. For instance, precision machining ensures that the worm gear in rolling mill machinery achieves tight tolerances, which is vital for seamless operation in rolling processes. This stage also involves heat treatment to enhance the mechanical properties of the worm gear for metal rolling processes.

- Quality Control: After manufacturing, rigorous quality control checks are performed. This includes dimensional inspections and performance testing to ensure the worm gear in steel rolling systems meets industry standards. Any defects are identified and rectified, guaranteeing that the heavy-duty worm gear for rolling mills operates efficiently and reliably under stress during production.

- Assembly and Integration: The final step involves the assembly of the worm gear with other components in rolling mill machinery. This integration is crucial, as the performance of the worm gear is directly linked to the overall efficiency of the rolling mill. Proper installation ensures optimal functionality, allowing for smoother operations in various worm gear applications in rolling mills.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, positioning us as one of the top ten worm gear suppliers in the region. Our expertise in worm gears is a key asset, particularly in rolling mills where precision and reliability are paramount.

- We offer a wide range of worm gear products, all manufactured to the highest quality standards.

- Our products are renowned for their exceptional durability and performance, making them ideal for demanding industrial applications.

- RP Techniek BV prides itself on our strong service capabilities, ensuring that our clients receive timely support and expert guidance.

- With a commitment to excellence, we continually invest in improving our offerings, ensuring we meet the evolving needs of the market.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...