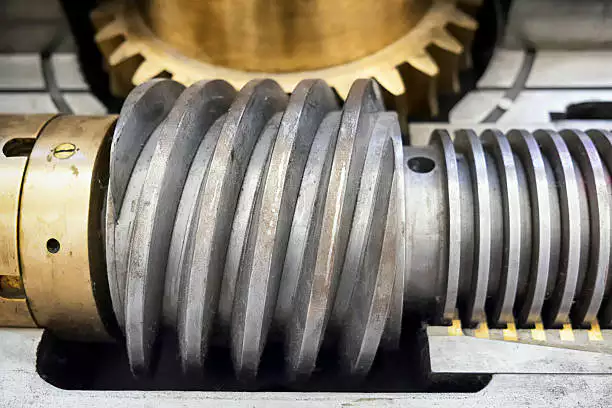

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Automated Assembly Lines

Worm gears play a crucial role in automated assembly lines, providing efficient torque transmission and compact design. In assembly line automation, worm gears are essential for controlling the movement of various components, ensuring precision and reliability. The automated assembly worm gear uses help in reducing backlash and enhancing the overall performance of production lines. Additionally, a precision worm gear for assembly is vital in robotic assembly systems, allowing for smooth and controlled operations that optimize productivity in modern manufacturing environments.

Specifications of Worm Gear in Automated Assembly Lines

| Spécification | Details |

|---|---|

| Gear Ratio | 10:1 |

| Matériel | Aluminum Alloy |

| Load Capacity | 500 Nm |

| Output Speed | 100 RPM |

| Efficiency | 85% |

| Temperature Range | -20 to 100 °C |

Why Worm Gears are Suitable for Worm Gear in Automated Assembly Lines

- Worm gears provide high torque and low speed, making them ideal for worm gear in assembly line automation.

- They facilitate smooth and precise movements, ensuring accuracy in automated assembly worm gear uses.

- The compact design of worm gears fits well in production lines, optimizing space and efficiency.

- In robotic assembly, worm gear systems enhance control and stability, crucial for precision worm gear for assembly applications.

- Worm gears are also self-locking, preventing backdrive and ensuring safety in automated processes.

How Worm Gears Work in Automated Assembly Lines

Worm gears play a crucial role in automated assembly lines, offering efficient solutions for various applications. The design of a worm gear in automated assembly lines allows for high torque transmission and compact configurations, making it ideal for assembly line automation. These gears enable precise movements required in robotic assembly tasks. Automated assembly worm gear uses are particularly advantageous in production lines where space is limited and precision is essential. With a focus on reliability, a precision worm gear for assembly ensures smooth operation, minimizing downtime and enhancing productivity. The integration of worm gear in robotic assembly contributes to the overall efficiency and effectiveness of modern manufacturing processes.

Manufacturing Process of Worm Gear in Automated Assembly Lines

- Design and Development: The first step in the manufacturing process of worm gear in automated assembly lines involves designing the gear for specific applications. Engineers use advanced software to create precise models that ensure compatibility with assembly line automation. The design phase focuses on achieving optimal torque transmission and efficiency, which is crucial for the performance of the automated assembly worm gear. This stage also considers factors like material selection and load-bearing capacity, ensuring the worm gear for production lines meets industry standards.

- Material Selection: High-quality materials are essential for the durability and performance of the worm gear in assembly line automation. Common materials include stainless steel and hardened alloys, which provide strength and corrosion resistance. The choice of material impacts the gear’s lifespan and operational efficiency. Selecting the right material is crucial for ensuring the precision worm gear for assembly can endure the stresses of robotic assembly processes.

- Manufacturing Techniques: Various manufacturing techniques are employed to produce worm gears, including machining, casting, and forging. Machining involves cutting the gear from a solid piece of material to achieve precise dimensions and surface finishes. Casting allows for complex shapes and is often used for large production runs. These techniques ensure that the automated assembly worm gear uses the most effective production methods, allowing for high precision and efficiency in assembly line operations.

- Quality Control: Quality control is critical in the manufacturing of worm gear in robotic assembly. Throughout the production process, each gear undergoes rigorous testing to check for dimensional accuracy, material integrity, and performance under load. This ensures that only the highest quality components are used in automated assembly lines, reducing the risk of failure in production environments. Consistent quality checks contribute to the reliability and efficiency of the entire assembly line automation system.

- Assembly and Integration: Once produced, the worm gears are assembled into the required automation systems. This phase involves integrating the precision worm gear for assembly into existing machinery, ensuring that it works seamlessly with other components. Proper assembly is vital for the overall functionality of automated assembly lines, as any misalignment can lead to operational issues. The effective integration of the worm gear in assembly line automation enhances productivity and reduces downtime in robotic assembly.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our company specializes in providing high-quality worm gears that are essential for automated assembly lines.

- Exceptional Quality: Our products are manufactured using state-of-the-art technology, ensuring that they meet the highest industry standards.

- Superior Performance: We offer worm gears that are designed for durability and reliability, providing optimal performance in various applications.

- Strong Expertise: With years of experience in the field, we have developed a deep understanding of customer needs and market trends.

- Excellent Service: Our dedicated team is committed to providing comprehensive support and guidance, ensuring customer satisfaction at every step.

Informations Complémentaires

| Edited | Zqq |

|---|

Blogs mis à jour

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...