In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Caractéristiques

The H87 Mill Chain is designed with the following parameters:

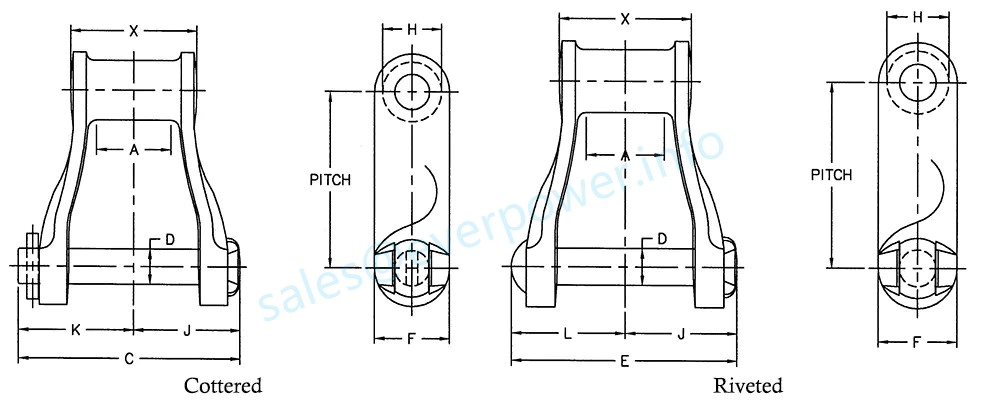

| CHAIN NO. | LINKS | PINS | PITCH IN INCHES | LINKS PER 10 FEET | WEIGHT PER FOOT LBS. | AVERAGE ULTIMATE STRENGTH LBS. | RECOMMENDED MAXIMUM WORKING LOAD LBS. | CHAIN CONSTRUCTION | AVAILABLE ATTACHMENTS | MAXIMUM ALLOWABLE SPROCKET FACE A | OVERALL WIDTH¡ª COTTERED C | DIAMETER OF PIN D | OVERALL WIDTH¡ª RIVETED E | HEIGHT OF SIDEBARS F | DIAMETER OF BARREL H | HEAD OF PIN TO CENTER LINE J | END OF PIN TO CENTER LINE¡ª COTTERED K | END OF PIN TO CENTER LINE¡ª RIVETED L | BEARING LENGTH X |

| H 60 | ALL NUMBERS A-L Primal |

ALL NUMBERS Carbon Steel, Heat-Treated | 2.308 | 52 | 2.1 | 9450 | 1560 | Riveted or Cottered | H2, K1 | 0.75 | 2.62 | 0.312 | 2.62 | 0.75 | 0.75 | 1.25 | 1.38 | 1.38 | 1.50 |

| H 74 | 2.609 | 46 | 3.0 | 13500 | 1850 | Riveted or Cottered | F4 | 1.00 | 3.12 | 0.375 | 2.88 | 1.00 | 0.88 | 1.50 | 1.62 | 1.62 | 1.66 | ||

| H 78 | 2.609 | 46 | 4.2 | 22200 | 2810 | Riveted or Cottered | A1, F4, F8, G19, H1, H2, K1, K2 | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 79 | 2.609 | 46 | 4.8 | 24300 | 2810 | Riveted or Cottered | None | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 82 | 3.075 | 39 | 5.5 | 27000 | 3580 | Riveted or Cottered | K2 | 1.25 | 3.88 | 0.562 | 3.88 | 1.25 | 1.22 | 1.88 | 2.00 | 2.00 | 2.12 | ||

| H 87 | 4.000 | 30 | 6.5 | 33750 | 4450 | Riveted or Cottered | None | 1.50 | 4.38 | 0.625 | 4.19 | 1.38 | 1.38 | 2.06 | 2.12 | 2.12 | 2.38 | ||

| H 124 | 4.000 | 30 | 8.8 | 40500 | 6180 | Riveted or Cottered | K2 | 1.62 | 4.88 | 0.750 | 4.75 | 1.56 | 1.44 | 2.25 | 2.50 | 2.50 | 2.75 |

Introduction

Discover the unparalleled performance and reliability of the H87 Mill Chain, designed to meet the most demanding industrial applications. This exceptional product offers cutting-edge technology and exceptional durability, making it the top choice for professionals in the field.

Unmatched Strength and Durability

The H87 Mill Chain is engineered with advanced materials and state-of-the-art manufacturing techniques, ensuring unmatched strength and durability. Its robust construction enables it to withstand heavy loads, extreme temperatures, and harsh environments, providing exceptional performance and longevity.

Enhanced Efficiency and Precision

Experience enhanced efficiency and precision with the H87 Mill Chain. Its meticulously designed components and precise engineering allow for smooth operation and minimal energy loss. This results in improved productivity, reduced downtime, and optimized performance, giving you a competitive edge in your industry.

Advanced Lubrication System

The H87 Mill Chain incorporates an advanced lubrication system that ensures reliable and consistent lubrication to all critical components. This innovative feature reduces friction, minimizes wear and tear, and extends the lifespan of the chain, ultimately reducing maintenance costs and enhancing overall operational efficiency.

Customizable Options

The H87 Mill Chain offers customizable options to cater to specific application requirements. With various sizes, configurations, and accessories available, you can tailor the chain to meet your unique needs. Our team of experts is ready to assist you in selecting the perfect combination of features, guaranteeing optimal performance and maximum customer satisfaction.

Industry-leading Customer Support

At H87, we prioritize customer satisfaction and provide industry-leading customer support. Our knowledgeable and experienced team is dedicated to assisting you throughout the entire product lifecycle, from selection and installation to troubleshooting and maintenance. We are committed to ensuring your success and maximizing the value you derive from our products.

Conclusion

When it comes to reliability, durability, and performance, the H87 Mill Chain stands above the rest. With its unmatched strength, enhanced efficiency, and advanced features, it is the ultimate solution for industrial applications. Experience the difference and elevate your operations to new heights with the H87 Mill Chain.

Choose Our Malleable Casting Chains

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands. Our company takes pride in offering a wide range of malleable cast iron chains, including the H87 Mill Chain.

Our malleable cast iron chains are known for their exceptional quality and durability. They are meticulously crafted to withstand heavy loads and harsh operating conditions. With our chains, you can expect reliable performance and extended service life.

At RP Techniek BV, we prioritize customer satisfaction and provide excellent service. Our team is dedicated to assisting you throughout the entire process, from selecting the right casting chains to after-sales support. We value long-term partnerships with our customers and strive to exceed their expectations.

In addition to our malleable casting chains, we also offer various other types of casting chains. Whatever your specific requirements may be, we have a solution for you.

For more information about our products and services, please visit our website: [insert website URL here].

[insert image here]

Image source: https://netherlandsdrive.com/wp-content/uploads/2024/10/chain-manufacturer.webp

Sprockets for Sale

When it comes to the perfect pairing with the H87 Mill Chain, our company offers a wide range of different types of sprockets for sale. Whether you need a standard, double pitch, or stainless steel sprocket, we have you covered. Our sprockets are designed to provide optimal performance and durability, ensuring smooth operation and longevity for your machinery.

With various tooth sizes and bore options available, you can easily find the right sprocket to match your H87 Mill Chain. Our sprockets are manufactured using high-quality materials and undergo rigorous testing to meet industry standards. They are built to withstand heavy loads and harsh working conditions, providing reliable power transmission for your mill operations.

At our company, we understand the importance of having the right equipment for your business. That's why we offer a comprehensive selection of sprockets, ensuring that you can find the perfect fit for your specific needs. Whether you are in the lumber industry, steel mills, or any other sector requiring mill chain applications, we have the sprockets to keep your operations running smoothly.

Informations Complémentaires

| Editor | Zqq |

|---|

Blogs mis à jour

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...