EPRV series small worm gearboxes are a critical component in machinery, providing power transmission and torque conversion. Assembly of these gearboxes requires a precise and well-planned process to ensure optimal performance and longevity. In this article, we will explore the assembly process for EPRV series small worm gearboxes in detail.

Introduction to EPRV Series Small Worm Gearboxes

EPRV series small worm gearboxes are compact and lightweight, making them ideal for use in small machinery. They have a high torque density, which means they can transmit a lot of power in a small package. EPRV series small worm gearboxes come in a range of sizes and configurations to suit different applications. They are commonly used in conveyor systems, printing presses, packaging machinery, and other types of machinery that require precise and reliable power transmission.

Assembly Process for EPRV Series Small Worm Gearboxes

The assembly process for EPRV series small worm gearboxes involves several steps:

Step 1: Preparation of Components

The first step in the assembly process is the preparation of components. This involves cleaning and inspecting all the parts to ensure that they are free from dirt, debris, or damage. It is important to use the correct lubricant for the gearbox, as this can affect its performance and longevity.

Step 2: Mounting of Bearings

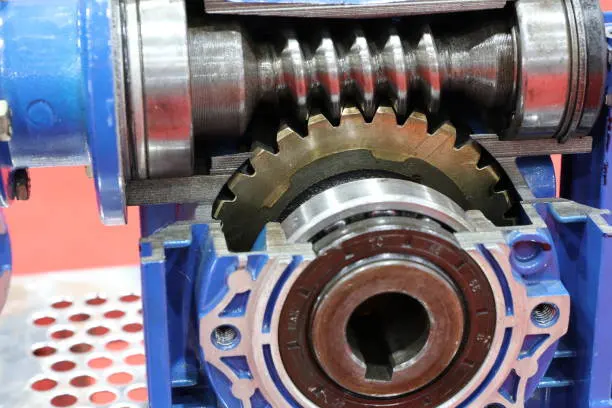

The next step is the mounting of bearings. This involves placing the bearings onto the shafts and ensuring that they are correctly aligned. It is important to use the correct size and type of bearing for the gearbox to ensure optimal performance.

Step 3: Gear Installation

The third step is the installation of gears. This involves placing the gears onto the shafts and ensuring that they are correctly aligned. It is important to use the correct gear ratio for the gearbox to ensure optimal performance.

Step 4: Assembly of Housing

The fourth step is the assembly of the housing. This involves placing the gears and bearings into the housing and securing them in place. It is important to ensure that the housing is correctly aligned and that all the parts fit together snugly.

Step 5: Final Inspection

The final step is the inspection of the assembled gearbox. This involves checking that all the parts are correctly aligned and that there are no defects or damage. It is important to perform a test run to ensure that the gearbox is functioning correctly.

Elektromotoren zu verkaufen

Electric motors and gearboxes are complementary components in machinery, working together to provide power and torque. At RP Techniek BV, we offer a range of electric motors that are suitable for use with EPRV series small worm gearboxes. Our motors are designed to work seamlessly with our gearboxes to provide optimal performance and longevity. Contact us today to explore our range of electric motors and find the right one for your application.

Über uns

RP Techniek BV is the Dutch sales agent of the Ever-power Group, a comprehensive transmission equipment manufacturer that integrates research and development, manufacturing, and sales of speed reducers. With over 25 years of experience in the design, production, manufacture, and sales of gearboxes, we serve customers in Europe, America, Africa, Asia, and other regions. Our company has introduced advanced production equipment and testing equipment from home and abroad, and employs industry professionals and technicians to carry out innovative research and development and manufacturing.

We use standardized production management methods to strictly control every aspect of gearbox production. Our gearboxes are widely used in various industries, including the equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and so on. We strive to provide our customers with high-quality, high-energy-efficiency, and high-stability gearboxes at competitive prices. Our commitment to innovation and quality has earned us a reputation as a leading provider of transmission equipment.

Q&A

Q1: What is the torque density of EPRV series small worm gearboxes?

A1: EPRV series small worm gearboxes have a high torque density, which means they can transmit a lot of power in a small package.

Q2: What are EPRV series small worm gearboxes commonly used for?

A2: EPRV series small worm gearboxes are commonly used in conveyor systems, printing presses, packaging machinery, and other types of machinery that require precise and reliable power transmission.

Q3: What is the first step in the assembly process for EPRV series small worm gearboxes?

A3: The first step in the assembly process is the preparation of components, which involves cleaning and inspecting all the parts to ensure that they are free from dirt, debris, or damage.

Q4: What is the final step in the assembly process for EPRV series small worm gearboxes?

A4: The final step is the inspection of the assembled gearbox, which involves checking that all the parts are correctly aligned and that there are no defects or damage. It is important to perform a test run to ensure that the gearbox is functioning correctly.

Q5: What industries use EPRV series small worm gearboxes?

A5: EPRV series small worm gearboxes are widely used in various industries, including the equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and so on.

Bearbeitet von: Zqq.