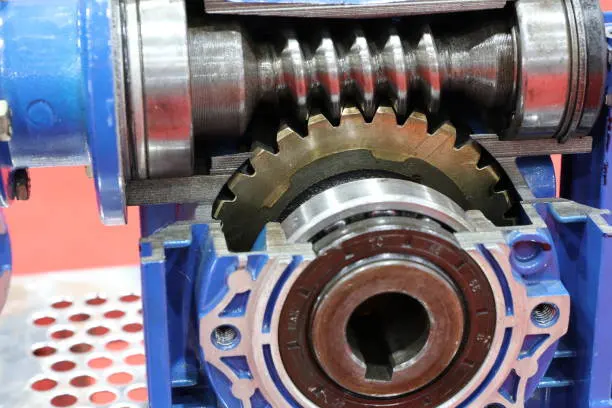

Small worm gearboxes are a critical component in various industrial applications. They are versatile, efficient, and reliable. In recent years, there have been several innovations in the development of small worm gearboxes. These innovations aim to enhance their performance, durability, and efficiency. This article will explore some of the latest innovations in the small worm gearbox industry.

1. Introduction

The EPRV series small worm gearbox is a highly-efficient gearbox used in various industrial applications. It is known for its reliability, versatility, and durability. In recent years, there have been several innovations in the development of EPRV series small worm gearboxes. These innovations have enhanced the performance and efficiency of these gearboxes. This article will explore some of these innovations and their benefits.

2. Hollow Shaft Design

The hollow shaft design is one of the latest innovations in small worm gearboxes. It is designed to reduce the weight of the gearbox and improve its efficiency. This design allows the shaft to pass through the gearbox, reducing the size and weight of the gearbox. Additionally, it reduces the amount of material needed to manufacture the gearbox, making it more cost-effective.

3. High-Torque Capacity

The high-torque capacity is another key innovation in small worm gearboxes. It is designed to provide more torque than traditional gearboxes. This increased torque capacity allows for the gearbox to handle higher loads and operate more efficiently. This innovation has made small worm gearboxes more versatile and adaptable to various industrial applications.

4. Compact Design

The compact design is another recent innovation in small worm gearboxes. It is designed to reduce the size and weight of the gearbox while maintaining its performance and efficiency. This design allows for the gearbox to be used in smaller spaces and applications where larger gearboxes cannot fit. Additionally, it reduces the amount of material needed to manufacture the gearbox, making it more cost-effective.

5. Improved Efficiency

Improved efficiency is a critical innovation in small worm gearboxes. It is designed to reduce the amount of energy needed to operate the gearbox. This innovation has resulted in significant energy savings for industrial applications. Additionally, it has reduced the carbon footprint of industrial operations, making them more environmentally-friendly.

6. Advanced Materials

The use of advanced materials is another significant innovation in small worm gearboxes. It is designed to improve the durability and lifespan of the gearbox. Advanced materials, such as carbon fiber and titanium, are used to manufacture the gearbox, making it more resistant to wear and tear. Additionally, it reduces the amount of maintenance needed for the gearbox, making it more cost-effective.

7. Electric motors for Sale

Electric motors and small worm gearboxes are complementary components in various industrial applications. Electric motors provide the power needed to operate the gearbox and drive industrial processes. Our company offers a range of electric motors that are designed to work seamlessly with small worm gearboxes. Our electric motors are efficient, reliable, and cost-effective. They are suitable for various industrial applications, such as conveyor systems, cranes, and packaging machines.

8. About Us

RP Techniek BV is the official sales representative of Ever-power Group in the Netherlands. We are a comprehensive transmission equipment manufacturer that specializes in research and development, manufacturing, and sales of speed reducers. With over 25 years of experience in the industry, we have established ourselves as a reliable and reputable manufacturer of high-quality gearboxes. Our gearboxes are used in various industrial applications, such as the food industry, car washing industry, packaging industry, and automation industry.

At RP Techniek BV, we are committed to providing our customers with the highest quality products and services. We employ industry professionals and technicians to carry out innovative research and development and manufacturing. We use standardized production management methods to ensure the highest quality products are manufactured. Our focus on quality has won us the trust and loyalty of our customers.

If you are interested in exploring our EPRV series small worm gearboxes or electric motors for sale, please contact us today. Our team of experts will be happy to assist you in finding the right solution for your industrial application needs.

Fragen und Antworten

Q1: What is the EPRV series small worm gearbox?

A1: The EPRV series small worm gearbox is a highly-efficient gearbox used in various industrial applications. It is known for its reliability, versatility, and durability.

Q2: What is the hollow shaft design?

A2: The hollow shaft design is one of the latest innovations in small worm gearboxes. It is designed to reduce the weight of the gearbox and improve its efficiency. This design allows the shaft to pass through the gearbox, reducing the size and weight of the gearbox.

Q3: What is the high-torque capacity?

A3: The high-torque capacity is another key innovation in small worm gearboxes. It is designed to provide more torque than traditional gearboxes. This increased torque capacity allows for the gearbox to handle higher loads and operate more efficiently.

Q4: What are the benefits of using advanced materials in small worm gearboxes?

A4: The use of advanced materials, such as carbon fiber and titanium, in small worm gearboxes improves the durability and lifespan of the gearbox. This innovation has resulted in significant cost savings for industrial applications.

Q5: What are the main industrial applications for small worm gearboxes?

A5: Small worm gearboxes are used in various industrial applications, such as the food industry, car washing industry, packaging industry, and automation industry.

Bearbeitet von: Zqq.