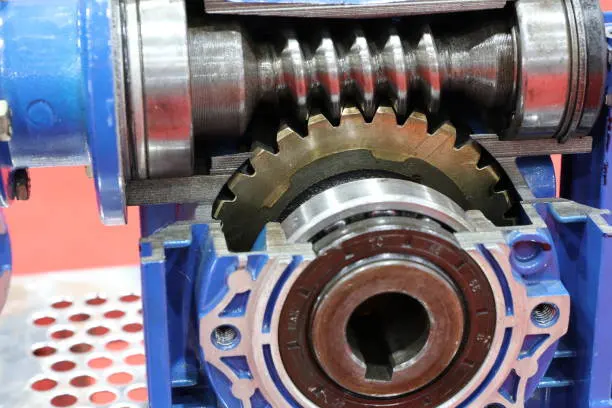

Worm gearboxes are an essential component in various industries, providing efficient power transmission and torque amplification. EPRV Series small worm gearboxes, in particular, have gained popularity due to their compact size and high-performance capabilities. In this article, we will explore the certifications that these gearboxes should have, ensuring their quality and reliability in demanding applications.

1. ISO 9001:2015 Certification

ISO 9001:2015 certification is crucial for EPRV Series small worm gearboxes as it establishes the manufacturer's commitment to quality management systems. This certification ensures that the gearbox production processes adhere to international standards, guaranteeing consistent performance and customer satisfaction.

2. CE Certification

CE certification is another essential requirement for EPRV Series small worm gearboxes. It demonstrates compliance with the European Union's safety, health, and environmental protection standards. This certification assures customers that the gearboxes meet stringent regulations, making them suitable for use in the European market.

3. IP Rating Certification

IP rating certification is crucial for EPRV Series small worm gearboxes, especially when they are intended for outdoor or harsh environments. This certification indicates the gearbox's resistance to dust and water ingress, ensuring reliable performance and longevity in challenging conditions.

4. RoHS Compliance

RoHS (Restriction of Hazardous Substances) compliance is essential for EPRV Series small worm gearboxes, especially in industries where environmental protection is a priority. This certification ensures that the gearboxes are free from hazardous substances such as lead, mercury, and cadmium, minimizing their impact on the environment.

5. UL Certification

UL certification is crucial for EPRV Series small worm gearboxes destined for the North American market. This certification demonstrates compliance with safety standards set by Underwriters Laboratories, ensuring the gearboxes' electrical safety and preventing potential hazards.

6. IECEx Certification

IECEx certification is important for EPRV Series small worm gearboxes used in hazardous environments where explosive gases or dust may be present. This certification ensures that the gearboxes are designed and manufactured to meet strict international standards for electrical equipment used in explosive atmospheres.

7. ATEX Certification

ATEX certification is necessary for EPRV Series small worm gearboxes intended for use in potentially explosive atmospheres within the European Union. This certification guarantees that the gearboxes meet the safety and performance requirements outlined in the ATEX directive.

8. Efficiency and Load Capacity Testing

In addition to certifications, EPRV Series small worm gearboxes should undergo efficiency and load capacity testing. These tests validate the gearboxes' performance, efficiency, and ability to handle specified loads, ensuring their suitability for various industrial applications.

9. Product Lifetime Testing

Product lifetime testing is crucial to ensure the durability and longevity of EPRV Series small worm gearboxes. By subjecting the gearboxes to rigorous testing under extreme conditions, manufacturers can determine their expected lifespan, helping customers make informed decisions regarding their applications.

10. Conclusion

In conclusion, EPRV Series small worm gearboxes should have various certifications to guarantee their quality, safety, and performance. Certifications such as ISO 9001:2015, CE, IP rating, RoHS, UL, IECEx, and ATEX demonstrate compliance with international standards and regulations. Additionally, efficiency and load capacity testing, along with product lifetime testing, ensure the gearboxes' suitability for diverse industrial applications. With these certifications and testing processes in place, customers can have confidence in the reliability and performance of EPRV Series small worm gearboxes.

Elektromotoren zu verkaufen

Electric motors and gearboxes are inseparable components in various industrial applications. The gearbox, such as the EPRV Series small worm gearbox, provides torque amplification and speed reduction, while the electric motor supplies the necessary power. The synergy between gearboxes and electric motors is crucial for achieving optimal performance and efficiency.

At our company, we understand the importance of this relationship, which is why we offer a wide range of electric motors for sale that are specifically designed to work seamlessly with our gearboxes. Our electric motors are highly efficient, reliable, and precisely matched to the power requirements of our gearboxes, ensuring optimal performance and energy savings.

Über uns

RP Techniek BV is the Dutch sales agent of Ever-power Group, a comprehensive transmission equipment manufacturer. With over 25 years of experience in design, production, manufacturing, and sales of gearboxes, we have established ourselves as a reputable and trusted company in the industry. Our primary customers are located in Europe and America, where we have earned a strong reputation for providing the highest quality products, competitive prices, and exceptional customer service.

At RP Techniek BV, we take pride in our production capabilities. We have introduced advanced production and testing equipment from both domestic and international sources. Our team of industry professionals and technicians conducts innovative research and development, ensuring that our gearboxes meet the highest standards of quality and performance. With standardized production management methods, we maintain strict control over every aspect of the production process, delivering high-quality, energy-efficient, and reliable gearboxes to our customers.

Our gearboxes find applications in a wide range of industries, including equipment manufacturing, food processing, car washing, packaging, transmission systems, automation, and solar energy. We welcome customers to explore our products and contact us for their gearbox needs. Our knowledgeable team is ready to assist and provide the best solution for their specific requirements.

Fragen und Antworten

Q1: Are EPRV Series small worm gearboxes suitable for high-speed applications?

A1: EPRV Series small worm gearboxes are primarily designed for low-speed and high-torque applications, making them less suitable for high-speed operations.

Q2: Can EPRV Series small worm gearboxes be used in extreme temperature conditions?

A2: Yes, EPRV Series small worm gearboxes can be designed to withstand extreme temperature conditions by using specialized materials and lubrication.

Q3: Are EPRV Series small worm gearboxes reversible?

A3: Yes, EPRV Series small worm gearboxes can be reversible depending on their design and configuration.

Q4: What maintenance is required for EPRV Series small worm gearboxes?

A4: Regular lubrication and inspection of the gearboxes are necessary to ensure optimal performance and longevity.

Q5: Can EPRV Series small worm gearboxes handle heavy loads?

A5: Yes, EPRV Series small worm gearboxes are designed to handle heavy loads, but their load capacity depends on the specific model and configuration.

Bearbeitet von: Zqq.