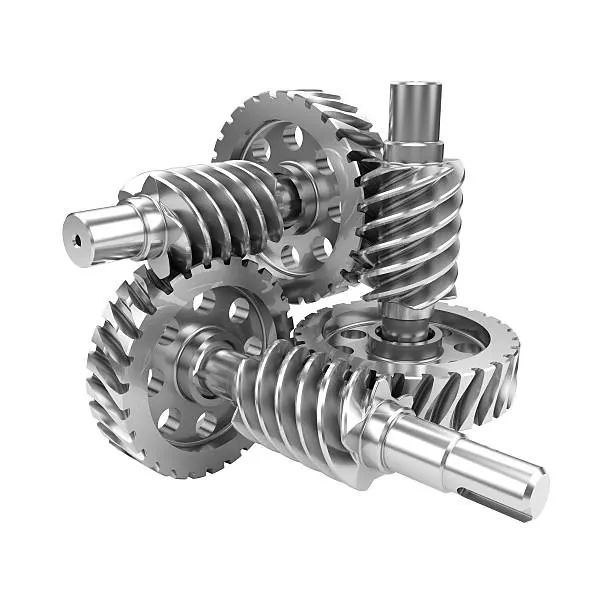

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

WPWDO Universal Speed Cast Iron Worm Gear Reducer: A Robust Solution for Industrial Applications

The WPWDO Universal Speed Cast Iron Worm Gear Reducer is a highly efficient and durable gearbox designed to meet the demanding needs of various industrial applications. With its model number WPD, this gearbox is highly regarded in the industry for its outstanding features and performance. Let's explore the key aspects of this gearbox.

Structure: Built to Last

The WPWDO Universal Speed Cast Iron Worm Gear Reducer features a cast iron housing that provides superior strength and durability. This robust structure ensures that the gearbox can withstand heavy loads and is resistant to damage from environmental factors. Furthermore, the gearbox offers a variety of ratios to choose from, allowing it to be adaptable to a wide range of industrial applications.

Features: Power, Efficiency, and Smooth Operation

Our WPWDO Universal Speed Cast Iron Worm Gear Reducer is equipped with a range of features that make it ideal for industrial applications:

- Highly efficient reduction ratios

- Self-locking function to prevent backdriving

- Exceptional durability and strength with cast iron housing

- Low noise operation

- Smooth and reliable performance

- Easy installation and maintenance

Specifications: Tailored to Your Requirements

The WPWDO Universal Speed Cast Iron Worm Gear Reducer comes with the following specifications:

| Model Number | Ratio | Input Speed (rpm) | Output Speed (rpm) | Output Torque (Nm) |

|---|---|---|---|---|

| WPD40-50 | 10, 15, 20, 25, 30, 40, 50 | 1500 | 30-150 | 59-245 |

| WPD40-60 | 10, 15, 20, 25, 30, 40, 50, 60 | 1500 | 30-125 | 58-210 |

Installation and Use: Ensuring Optimal Performance

Proper installation and use are crucial to maximizing the performance and lifespan of the WPWDO Universal Speed Cast Iron Worm Gear Reducer:

- Install the gearbox on a flat and sturdy base, tightening the foot bolts to prevent vibration

- Ensure accurate alignment of input and output shafts with driving and driven machines

- Choose appropriate tolerance sizes for coupling, pulleys, and transmission parts to avoid bearing damage and ensure efficient power transmission

- Place sprockets, gears, and other transmission parts close to the bearings to reduce shaft deflection and bending stress

- Apply grease to the worm head inner hole and keyway during motor assembly to prevent rusting

- Check the gearbox type, center distance specification, transmission ratio, input shaft connection method, output shaft structure, input and output shaft axis orientation, and rotation direction to ensure suitability for your application

- Use specified lubricants as recommended in the "Selection and Use of Lubricants" guide

- Regularly check and maintain proper lubrication levels, tighten the breather, and replace lubricating oil as needed

- Monitor for any abnormal conditions during operation and promptly address them

Possible Faults and Solutions

The WPWDO Universal Speed Cast Iron Worm Gear Reducer may encounter the following faults:

| Fault | Cause | Lösung |

|---|---|---|

| Überhitzung | Insufficient lubricant or improper lubricating method | Check and replace the lubricant |

| Vibration | Output shaft not concentric with input shaft | Adjust concentricity of input and output shafts |

| Noise | Gear meshing clearance too large or too small | Adjust gear meshing clearance |

| Leakage of lubricating oil | Damaged sealing or improper assembly | Check and replace the seal |

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...