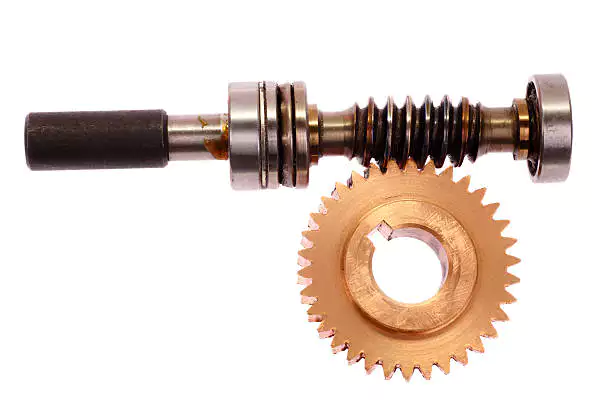

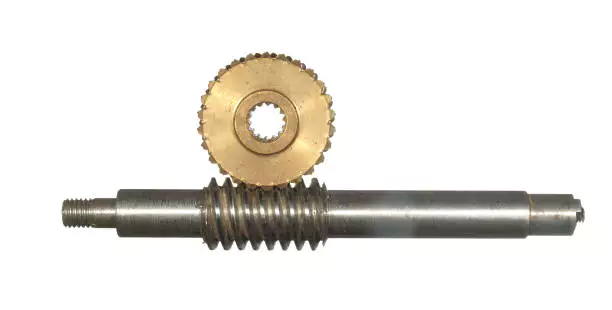

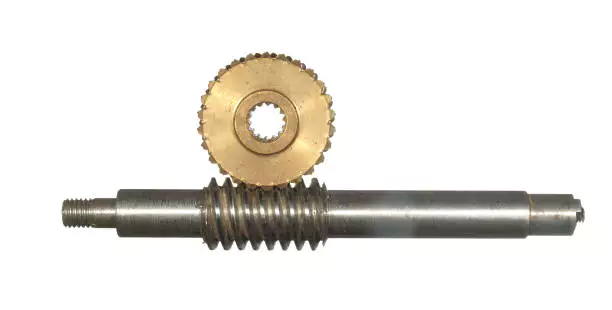

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear for Conveyor Belts

The worm gear for conveyor belts is a specialized component designed to enhance the efficiency of conveyor systems. This type of worm gear in conveyor systems provides smooth and controlled movement, crucial for transporting materials in various industries. Conveyor belt worm gear uses include reducing speed and increasing torque, making it ideal for worm gear for material handling. Its robust design ensures durability, and it plays a vital role in industrial worm gear for conveyors, optimizing performance in worm gear in conveyor engineering.

Specifications of Worm Gear for Conveyor Belts

| Feature | Details |

|---|---|

| Gear Ratio | 10:1 |

| Material | Aluminum Alloy |

| Load Capacity | 500 kg |

| Efficiency | 85% |

| Temperature Range | -20°C to 100°C |

| Input Shaft Diameter | 25 mm |

Why Worm Gears are Suitable for Worm Gear for Conveyor Belts Applications

- Worm gears for conveyor belts provide high torque and are efficient in transferring power, making them ideal for heavy-duty applications.

- The unique design of the worm gear in conveyor systems allows for compact installations, saving valuable space in industrial settings.

- Conveyor belt worm gear uses include material handling tasks that require precise control and minimal backlash.

- Worm gear for material handling offers smooth operation, which is critical in reducing wear on components.

- Industrial worm gear for conveyors ensures reliability and longevity, essential for continuous operations.

- Utilizing worm gear in conveyor engineering enhances system performance, particularly in applications requiring steep incline transportation.

How Worm Gears Work in Conveyor Belt Applications

Worm gears play a crucial role in conveyor belt systems, allowing for efficient material handling and movement. The design of a worm gear for conveyor belts enables smooth operation, minimizing slippage and maximizing torque. In conveyor systems, the worm gear’s ability to convert rotational motion into linear movement makes it ideal for a variety of applications. Conveyor belt worm gear uses include facilitating the transport of heavy materials and ensuring precise control of speed and direction. Industrial worm gear for conveyors is engineered to withstand high loads and provide durability, while worm gear in conveyor engineering enhances the overall efficiency of the system. With their unique mechanics, worm gears are essential for optimizing conveyor belt performance.

Manufacturing Process of Worm Gear for Conveyor Belts

- Design and Engineering: The first step in producing a worm gear for conveyor belts involves detailed design and engineering. This phase includes analyzing the application requirements, such as load capacity and speed, to create a robust worm gear suitable for conveyor systems. Engineers use advanced CAD software to develop precise specifications, ensuring that the worm gear in conveyor systems meets industry standards for durability and efficiency. The design process incorporates factors like material selection and gear ratio optimization, crucial for effective operation in material handling applications.

- Material Selection: Choosing the right materials is vital for the performance and longevity of the worm gear for conveyor belts. Typically, high-strength alloys or stainless steel are preferred for their durability and resistance to wear and corrosion. The selected materials must also be capable of withstanding the stresses encountered during operation in industrial worm gear for conveyors. This careful selection directly influences the gear's efficiency, ensuring it can handle the demands of various conveyor systems effectively.

- Manufacturing Techniques: The manufacturing of worm gears for conveyor belts employs various techniques, including precision machining and heat treatment. CNC machining is commonly used to achieve tight tolerances and high-quality finishes on the worm gear components. Following machining, heat treatment processes are applied to enhance the strength and wear resistance of the gear. This combination of techniques ensures that the worm gear in conveyor engineering is not only precise but also capable of operating under heavy loads and continuous usage.

- Assembly and Quality Control: After machining and heat treatment, the worm gears are assembled with other components such as shafts and housings. This assembly process must be executed with precision to ensure optimal engagement between the worm gear and the mating components. Rigorous quality control checks are conducted at this stage to assess the functionality and durability of the worm gear for material handling applications. Testing includes load tests and operational assessments to ensure that the product meets the required performance standards.

- Final Inspection and Packaging: The last step in the manufacturing process of a worm gear for conveyor belts involves a thorough final inspection. Each product is evaluated for dimensional accuracy, surface finish, and operational performance. Once the gears pass inspection, they are carefully packaged for shipment, ensuring they arrive in perfect condition. Proper packaging is essential to prevent damage during transit, allowing the worm gear in conveyor systems to be deployed efficiently and reliably in various industrial applications.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group, and we are proud to be one of the top ten worm gear suppliers in the Netherlands.

Our Worm Gear for Conveyor Belts offers a wide range of superior quality products that stand out in the industry. Here are the key features of our offerings:

- Exceptional Quality: Our worm gears are manufactured with precision, ensuring durability and reliability in various applications.

- Outstanding Performance: Designed for optimal efficiency, our products enhance the functionality of conveyor systems.

- Strong Reputation: With years of experience, we have established a solid reputation in the market for excellence.

- Comprehensive Service: Our dedicated team is committed to providing exceptional customer support, tailored solutions, and timely delivery.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...