In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

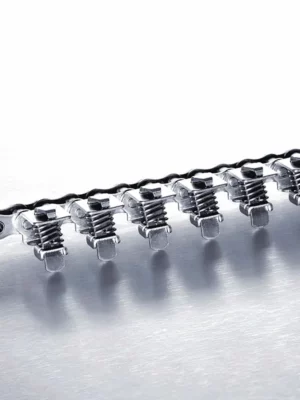

Details of Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125

Einführung

The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is a unique product designed for use in the metallurgical industry. The chain is made of high-quality stainless steel, making it durable and resistant to corrosion. It is designed for use in horizontal conveyors, where it can carry anodes used in the process of electrolysis. The chain is an essential component of the electrolysis process, and its quality is critical to the success of the process.

Material

The chain is made of high-quality stainless steel, which has excellent mechanical properties and is resistant to corrosion. The steel is alloyed with elements such as chromium, nickel, and molybdenum, which give it added strength and corrosion resistance. This ensures that the chain can withstand the harsh conditions of the metallurgical industry, including exposure to high temperatures, corrosive chemicals, and abrasive materials.

Design

The design of the Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is based on years of experience in the metallurgical industry. The chain is designed to be strong, durable, and resistant to corrosion. It has a unique shape that allows it to carry anodes of various sizes and weights. The chain is also designed to be easy to install and maintain, which reduces downtime and increases productivity.

Benefits

- Durable: The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is made of high-quality stainless steel, which makes it durable and long-lasting.

- Corrosion-resistant: The chain is resistant to corrosion, which ensures that it can withstand the harsh conditions of the metallurgical industry.

- Easy to install: The chain is designed to be easy to install, which reduces downtime and increases productivity.

- Low maintenance: The chain requires minimal maintenance, which saves time and money.

- Flexible: The chain can carry anodes of various sizes and weights, which makes it versatile and suitable for different applications.

Applications

The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is used in the metallurgical industry in the process of electrolysis. It is designed to carry anodes of various sizes and weights, which are used in the process of producing metals such as aluminum, copper, and zinc. The chain is an essential component of the electrolysis process, and its quality is critical to the success of the process.

Conclusion

The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is a high-quality product designed for use in the metallurgical industry. It is made of high-quality stainless steel, which makes it durable and resistant to corrosion. The chain is designed to be easy to install and maintain, which reduces downtime and increases productivity. It is an essential component of the electrolysis process, and its quality is critical to the success of the process.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. Our company takes pride in offering the Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125, which showcases our unique selling points and emphasizes the superior quality and service of our products. With our strong manufacturing capabilities, we ensure that our chains meet the highest standards in the industry.

In addition to the SSEA125, we also provide a wide range of other stainless steel roller chains for sale. Our diverse selection caters to various needs and requirements. Whether it's for industrial applications or specialized projects, we have the right chain to suit your needs.

How to Select Suitable Sprockets?

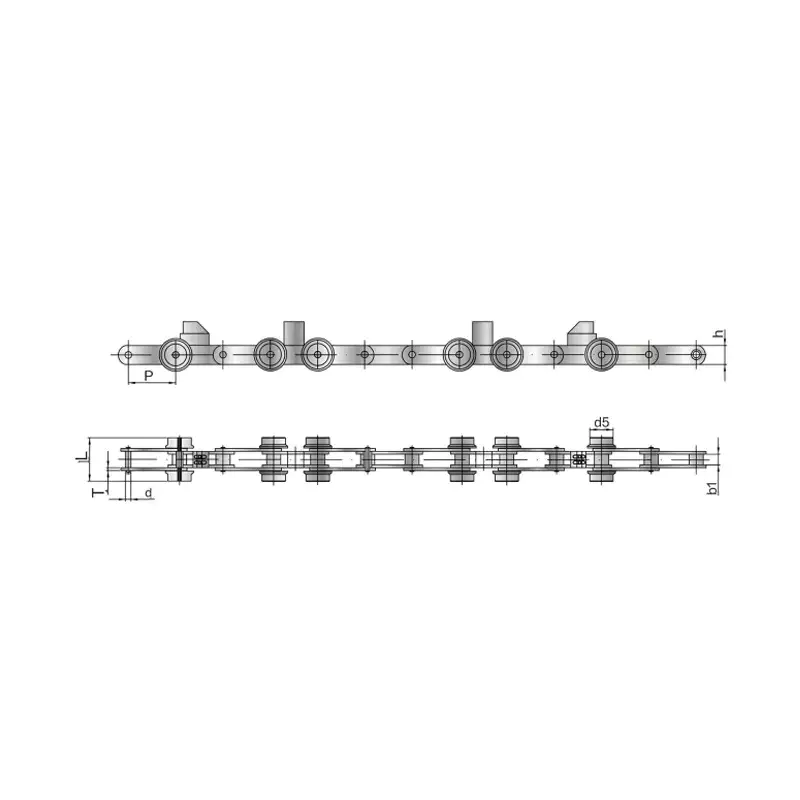

When it comes to selecting suitable sprockets for Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125, there are a few key factors to consider. Firstly, it is important to determine the pitch of the chain and choose a sprocket with a matching pitch to ensure proper engagement. Additionally, the number of teeth on the sprocket and the diameter of the bore must be carefully selected to ensure a proper fit and appropriate operating conditions.

At our company, we offer a wide range of sprockets in various sizes, pitches, and tooth counts to meet the specific needs of our customers. Our sprockets are made from high-quality materials and manufactured to strict standards to ensure durability and reliability in even the most demanding applications.

Please see the image below for an example of a sprocket that we offer:

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...