In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Technische Daten

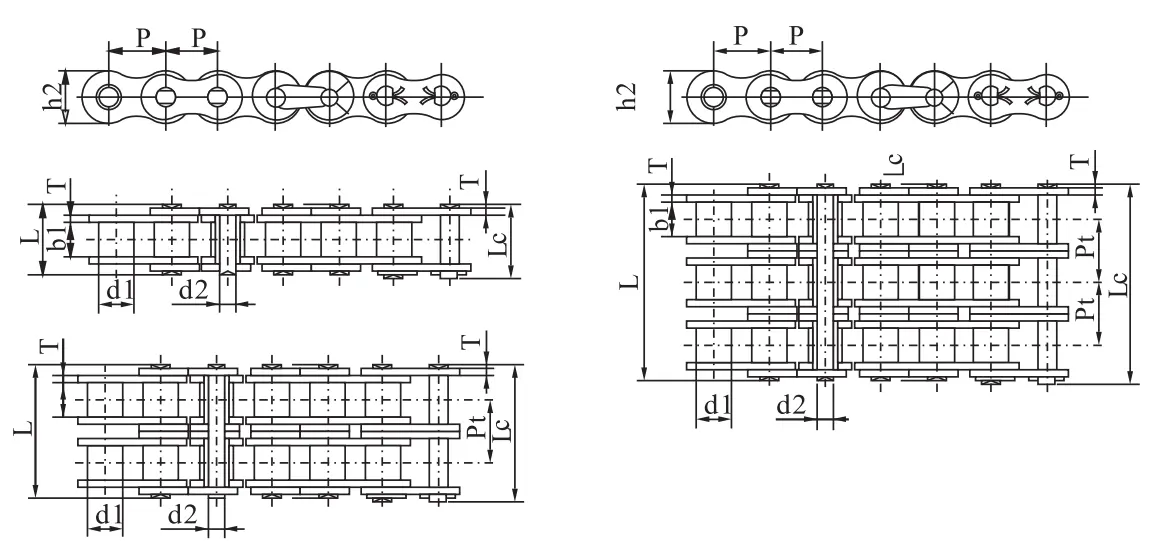

- Product: SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains

- Material: Stainless Steel

- Series: Heavy Duty

- Chain Type: Roller Chains

- Model: SS12AH-2/SS60H-2

This chain is designed to withstand heavy loads and harsh conditions, making it ideal for industrial applications. Made from high-quality stainless steel, it offers excellent corrosion resistance and durability. With its roller chain design, it ensures smooth and efficient power transmission. The SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains provide reliable performance in demanding environments.

| DIN/ISO Chain. NO. | ANSI

Chain. NO. |

Pitch | Roller Diameter |

Width Between Inner plates |

Pin

Diameter |

Pin Length | Inner Plate depth |

Plate Thick Ness |

Transverse Pitch |

Tensile Strength |

Gewicht Per Meter |

|

| P | dl max |

bl min |

d2 max |

L max |

Lc max |

h2 max |

T max |

Pt | Q min |

q. | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | Kg/m | ||

| SS08AH-1 | SS40H-1 | 12.7 | 7.95 | 7.85 | 3.96 | 18.8 | 19.9 | 12 | 2 | _ | 9.87 | 0.82 |

| SS10AH-1 | SS50H-1 | 15.875 | 10.16 | 9.4 | 5.08 | 22.1 | 23.4 | 15.09 | 2.4 | _ | 15.54 | 1.25 |

| SS12AH-1 | SS60H-1 | 19.05 | 11.91 | 12.57 | 5.94 | 29.2 | 31 | 18 | 3.2 | _ | 22.26 | 1.87 |

| SS16AH-1 | SS80H-1 | 25.4 | 15.88 | 15.75 | 7.92 | 36.2 | 37.7 | 24 | 4 | _ | 39.69 | 3.1 |

| SS20AH-1 | SS100H-1 | 31.75 | 19.05 | 18.9 | 9.53 | 43.6 | 46.9 | 30 | 4.8 | _ | 61.95 | 4.52 |

| SS24AH-1 | SS120H-1 | 38.1 | 22.23 | 25.22 | 11.1 | 53.5 | 57.5 | 35.7 | 5.6 | _ | 88.9 | 6.6 |

| SS28AH-1 | SS140H-1 | 44.45 | 25.4 | 25.22 | 12.7 | 57.6 | 62.2 | 41 | 6.4 | _ | 120.68 | 8.3 |

| SS32AH-1 | SS160H-1 | 50.8 | 28.58 | 31.55 | 14.27 | 68.2 | 73 | 47.8 | 7.2 | _ | 158.76 | 10.3 |

| SS36AH-1 | SS180H-1 | 57.15 | 35.71 | 35.48 | 17.46 | 75.9 | 81.6 | 53.6 | 8 | _ | 196.7 | 14.83 |

| SS40AH-1 | SS200H-1 | 63.5 | 39.68 | 37.85 | 19.85 | 86.6 | 93.5 | 60 | 9.5 | _ | 247.66 | 19.16 |

| SS48AH-1 | SS240H-1 | 76.2 | 47.63 | 47.35 | 23.81 | 109.61 | 115.9 | 72.3 | 12.7 | _ | 357.21 | 30.4 |

| SS12AH-2 | SS60H-2 | 19.05 | 11.91 | 12.57 | 5.94 | 55.3 | 57.1 | 18 | 3.2 | 26.11 | 44.52 | 3.71 |

| SS16AH-2 | SS80H-2 | 25.4 | 15.88 | 15.75 | 7.92 | 68.8 | 70.3 | 24 | 4 | 32.59 | 79.38 | 6.15 |

| SS20AH-2 | SS100H-2 | 31.75 | 19.05 | 18.9 | 9.53 | 82.7 | 86 | 30 | 4.8 | 39.09 | 123.9 | 9.03 |

| SS24AH-2 | SS120H-2 | 38.1 | 22.23 | 25.22 | 11.1 | 102.4 | 106.4 | 35.7 | 5.6 | 48.87 | 177.8 | 13.13 |

| SS28AH-2 | SS140H-2 | 44.45 | 25.4 | 25.22 | 12.7 | 109.8 | 114.4 | 41 | 6.4 | 52.2 | 241.36 | 16.6 |

| SS32AH-2 | SS160H-2 | 50.8 | 28.58 | 31.55 | 14.27 | 130.1 | 134.9 | 47.8 | 7.2 | 61.9 | 317.52 | 20.2 |

| SS40AH-2 | SS200H-2 | 63.5 | 39.68 | 37.85 | 19.85 | 164.9 | 171.8 | 60 | 9.5 | 78.31 | 495.32 | 38.11 |

| SS12AH-3 | SS60H-3 | 19.05 | 11.91 | 12.57 | 5.94 | 81.4 | 83.2 | 18 | 3.2 | 26.11 | 66.78 | 5.54 |

| SS16AH-3 | SS80H-3 | 25.4 | 15.88 | 15.75 | 7.92 | 101.4 | 102.9 | 24 | 4 | 32.59 | 119.07 | 9.42 |

| SS20AH-3 | SS100H-3 | 31.75 | 19.05 | 18.9 | 9.53 | 121.8 | 125.1 | 30 | 4.8 | 39.09 | 185.85 | 12.96 |

| SS24AH-3 | SS120H-3 | 38.1 | 22.23 | 25.22 | 11.1 | 151.2 | 155.2 | 35.7 | 5.6 | 48.87 | 266.7 | 19.64 |

| SS28AH-3 | SS140H-3 | 44.45 | 25.4 | 25.22 | 12.7 | 162 | 166.6 | 41 | 6.4 | 52.2 | 362.04 | 24.9 |

| SS32AH-3 | SS160H-3 | 50.8 | 28.58 | 31.55 | 14.27 | 192 | 196.8 | 47.8 | 7.2 | 61.9 | 476.28 | 30.1 |

| SS40AH-3 | SS200H-3 | 63.5 | 39.68 | 37.85 | 19.85 | 243.2 | 250.1 | 60 | 9.5 | 78.31 | 742.98 | 57.06 |

Einführung

SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains are specifically designed for heavy-duty applications in harsh environment. These chains are made of high-quality stainless steel offering superior corrosion resistance, strength, and durability. The chains are engineered to provide reliable performance and long service life even in the most demanding applications.

Features and Specifications

- Material: High-quality stainless steel

- Pitch Size: SS12AH-2 (3/4 inch), SS60H-2 (1 inch)

- Roller Diameter: SS12AH-2 (0.469 inch), SS60H-2 (0.750 inch)

- Link Plate Thickness: SS12AH-2 (0.125 inch), SS60H-2 (0.156 inch)

- Pin Diameter: SS12AH-2 (0.234 inch), SS60H-2 (0.375 inch)

- Operating Temperature: -40¡ãF to +750¡ãF (-40¡ãC to +400¡ãC)

- Corrosion Resistance: Excellent

- Load Capacity: High

- Pre-Lubrication: Yes

Applications

SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains are suitable for use in a variety of applications where high strength, durability, and corrosion resistance are required. Some of the common applications include:

- Food processing equipment

- Chemical processing equipment

- Pharmaceutical equipment

- Packaging machinery

- Pulp and paper mills

- Mining equipment

Installation and Maintenance

Proper installation and maintenance are critical for ensuring the optimal performance and long service life of SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains. Here are some guidelines to follow:

- Inspect the chain for damage or wear before installation

- Ensure proper tensioning and alignment during installation

- Lubricate the chain as per the manufacturer's recommendations

- Regularly clean and inspect the chain for wear and damage

- Replace the chain if it shows signs of excessive wear or elongation

Conclusion

SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains are the ideal choice for heavy-duty applications where strength, durability, and corrosion resistance are critical. These chains offer superior performance and reliability, making them a cost-effective solution for a wide range of industries and applications.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agency of Ever-power Group in the Netherlands. We are proud to introduce our SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains as a unique selling point. Our chains are designed to meet the high-quality standards of the industry and are durable enough to withstand harsh environments.

Our stainless steel roller chains undergo a strict quality control process to ensure that they meet the required standards. Our team of experts is committed to providing high-quality products and services to our customers. We strive to exceed our customers' expectations by delivering our products on time and offering excellent customer service.

At RP Techniek BV, we have the production capacity to meet large orders, and we can customize our chains according to our customer's needs. Our team of skilled professionals is dedicated to providing high-quality products and services to our customers.

In addition to our SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains, we also offer various other types of stainless steel roller chains for sale. Our products are suitable for a wide range of applications, including food processing, packaging, and other industrial applications.

Sprockets for Sale

If you are looking for chain sprockets that are suitable for the SS12AH-2/SS60H-2 Heavy Duty Series Stainless Steel Roller Chains, look no further. Our company offers a wide range of different types of sprockets for sale, including those that are compatible with these high-quality chains.

Our sprockets are made from durable materials such as stainless steel, and are designed to withstand heavy loads and extreme operating conditions. We offer both standard and custom sprockets to meet the needs of a variety of industries and applications.

Whether you need a sprocket for a conveyor system, a power transmission application, or any other industrial use, we have the solution for you. Our experienced team can help you select the right sprocket for your specific needs and provide expert advice on installation and maintenance.

Don't settle for inferior sprockets. Choose our high-quality, reliable products to keep your equipment running smoothly and efficiently. Contact us today to learn more about our sprockets for sale.

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...