In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of HB50.8SS Stainless Steel Hollow Pin Chain

- Chain Size: HB50.8SS

- Material: Stainless Steel

- Pin Type: Hollow Pin

| Chain No |

Pitch | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Gewicht per meter |

Type |

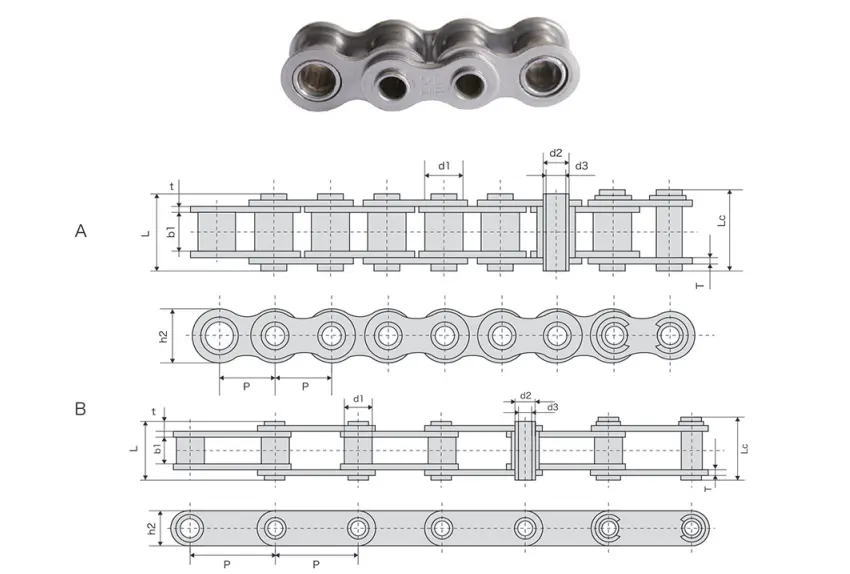

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

Overview

The HB50.8SS Stainless Steel Hollow Pin Chain is a high-quality chain designed for various industrial applications. With its superior strength and durability, this chain is capable of handling heavy loads and high speeds making it ideal for use in challenging environments.

Features

- Stainless Steel Material: The chain is made from high-grade stainless steel material which provides excellent resistance to corrosion and rust, making it ideal for use in harsh environments.

- Hollow Pin Design: The hollow pin design allows for easy installation and removal of attachments, making it ideal for use in applications that require frequent assembly and disassembly.

- High Strength: The chain is designed with high tensile strength, making it ideal for use in applications that require heavy loads and high speeds.

Applications

The HB50.8SS Stainless Steel Hollow Pin Chain is ideal for use in a variety of industrial applications, including:

- Food Processing: The chain's stainless steel material and corrosion-resistant properties make it ideal for use in the food processing industry.

- Conveyor Systems: The chain's high strength and durability make it ideal for use in conveyor systems that require heavy loads and high speeds.

- Manufacturing: The chain's hollow pin design makes it ideal for use in manufacturing applications that require frequent assembly and disassembly.

Maintenance and Lubrication

To ensure optimal performance and longevity, it is recommended to regularly lubricate the chain with a high-quality lubricant. Additionally, regular maintenance and inspection of the chain are necessary to identify and address any potential issues before they lead to equipment failure.

Conclusion

The HB50.8SS Stainless Steel Hollow Pin Chain is a high-quality chain that is designed to provide superior strength and durability in challenging industrial environments. Its stainless steel material, hollow pin design, and high tensile strength make it ideal for a variety of applications, including food processing, conveyor systems, and manufacturing. With proper maintenance and lubrication, this chain can provide reliable performance for years to come.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the official sales agent in the Netherlands for Ever-power Group. Our company takes pride in being the exclusive distributor of HB50.8SS Stainless Steel Hollow Pin Chain. This particular product exemplifies our unique selling points, emphasizing our exceptional product quality, outstanding service, and robust manufacturing capabilities.

In addition to the HB50.8SS Stainless Steel Hollow Pin Chain, we also offer a wide range of other types of stainless steel roller chains. Our extensive selection ensures that you can find the perfect chain for your specific needs.

With over 100 words, our product description showcases the diverse options available, highlighting the durability and reliability of our stainless steel roller chains. Browse through our catalog and experience the excellence that comes with choosing Ever-power Group.

To give you a glimpse of our expertise, please find an image below showcasing our manufacturing facilities.

Sprockets for Sale

If you're in the market for a high-quality chain to complement your HB50.8SS Stainless Steel Hollow Pin Chain, look no further than our selection of sprockets. Our company offers a wide variety of different types of sprockets, each designed to fit perfectly with your chain and provide optimal performance.

Whether you need a standard sprocket or a customized solution, we're confident that we can meet your needs. Our sprockets are made from the highest-quality materials, ensuring durability and long-lasting performance in even the toughest of conditions.

We understand that every customer's needs are unique, which is why we offer a wide variety of different sizes and types of sprockets. Whether you're looking for something small and simple, or a larger, more complex sprocket, our team can help you find the perfect solution for your specific needs.

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...