In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

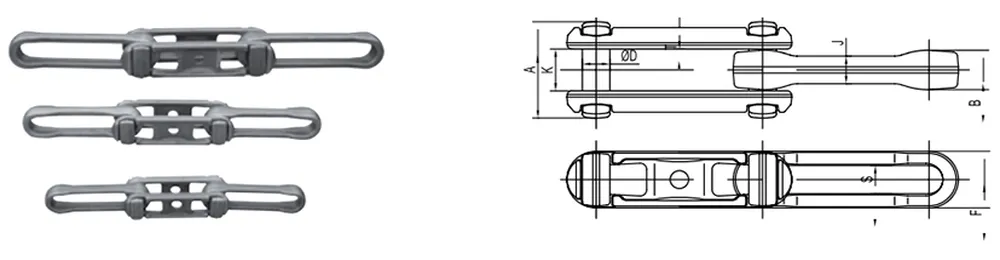

Drop Forged Rivetless Chain X348, X458, X678, X80, F100, S458, S348, S678, S698

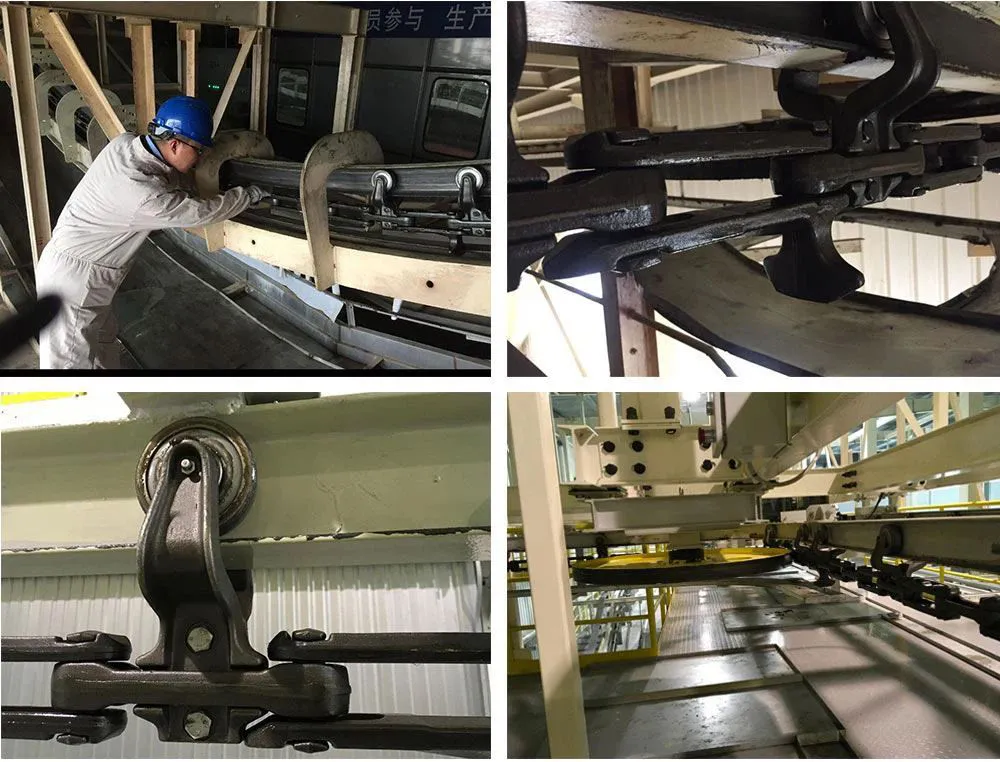

Drop forged rivetless chain is a robust industrial chain often used in conveyor systems for heavy-duty tasks. It is constructed from high-quality steel links, allowing it to support heavy loads and ensuring exceptional durability. A significant advantage of drop forged rivetless chains is that they don’t need pins or rivets, simplifying assembly and disassembly. This design also facilitates maintenance and repairs, as only the damaged or worn links need to be replaced.

Drop Forged Rivetless Chain X348, X458, X678, X80, F100, S458, S348, S678, S698,348, 458, 678, 698, 998, 9118, 80, 80H, XT 100, XT 160

Drop forged rivetless chain is an industrial chain frequently employed in conveyor systems, particularly for heavy-duty use. Constructed from high-quality forged steel links, this chain can withstand significant loads while offering exceptional durability. A notable advantage of drop forged rivetless chains is their lack of pins or rivets, which simplifies assembly and disassembly. This design also aids in maintenance and repair, as it only requires replacing broken or worn links.

These chains are commonly utilized in automotive factories, steel mills, food processing plants, and other demanding industrial environments. They are engineered to endure extreme temperatures, moisture, abrasion, and high-impact forces. In conclusion, drop forged rivetless chains provide a robust, reliable, and efficient solution for heavy-duty conveyor applications in various industries.

X-Type Drop Forged Rivetless Chain Specifications

| Chain No. | Pitch | Dimension(mm) | Later angle | Ultimate strength | Gewicht | |||||||

| mm | A | B | F | S | J | K | T | D | α | (KN) | (Kg/m) | |

| X348 Chain | 76.6 | 46 | 18.8 | 27 | 13.5 | 13.2 | 20.6 | 10.2 | 12.7 | 9 | 110 | 3.2 |

| X458 Chain | 102.4 | 56 | 25.4 | 36 | 17.4 | 16 | 26.5 | 12 | 16 | 9 | 220 | 4.7 |

| X678 Chain | 153.2 | 77 | 32 | 51 | 25 | 21 | 34.2 | 17 | 22 | 7 | 320 | 9.5 |

| X80 Chain | 80 | 46 | 18.8 | 27 | 13.5 | 13.2 | 20.6 | 6.3 | 12.7 | 6.5 | 110 | 3.1 |

| F100 Chain | 100 | 56 | 25 | 36 | 17.4 | 16 | 26.5 | 12 | 16 | 9 | 220 | 4.7 |

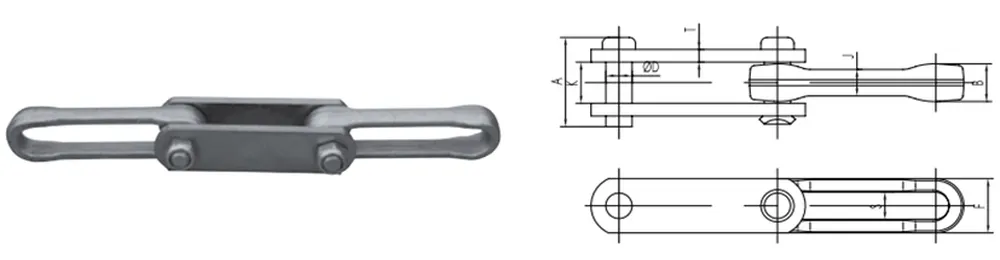

S-Type Rivetless Drop Forged/Bar Loop Chain Specifications

| Chain No. | Pitch | Dimension(mm) | Later angle | Ultimate strength | Gewicht | |||||||

| (mm) | A | B | F | S | J | K | T | D | α | (KN) | (Kg/m) | |

| S458 Chain | 102.4 | 49.5 | 25.4 | 36 | 17.4 | 16 | 27 | 7.8 | 16 | 9 | 220 | 4.7 |

| S348 Chain | 76.6 | 46 | 18.8 | 27 | 13.5 | 13.2 | 20.6 | 6.3 | 12.7 | 9 | 110 | 3.2 |

| S678 Chain | 153.2 | 66.6 | 32 | 51 | 25 | 21 | 34.2 | 12.7 | 22 | 7 | 320 | 9.5 |

| S698 Chain | 153.2 | 93 | 39.7 | 69.9 | 30.2 | 25.4 | 41.3 | 14.3 | 29.1 | 5 | 600 | 19.6 |

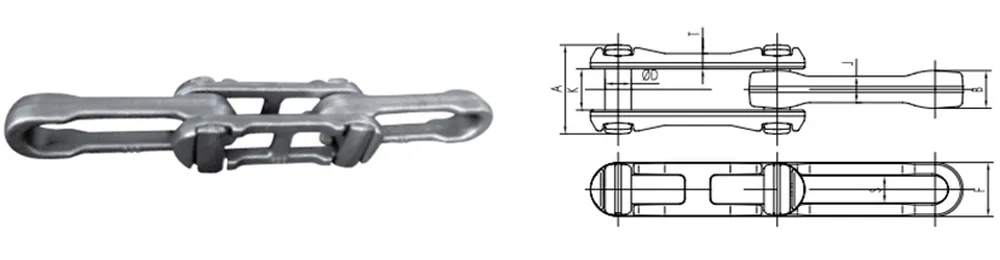

H-Type Drop Forged Rivetless Chain Specifications

| Chain No. | Pitch | Dimension(mm) | Later angle | Ultimate strength | Gewicht | |||||||

| (mm) | A | B | F | S | J | K | T | D | α | (KN) | (Kg/m) | |

| 348 Chain | 76.6 | 44.5 | 18.8 | 27 | 13.5 | 13.2 | 20.6 | 7.6 | 12.7 | 9 | 110 | 3.2 |

| 458 Chain | 102.4 | 58 | 25.4 | 36 | 17.4 | 16 | 26.5 | 8.5 | 16 | 9 | 220 | 4.7 |

| 678 Chain | 153.2 | 77 | 32 | 51 | 25 | 21 | 34.2 | 12 | 22 | 7 | 320 | 9.5 |

| 698 Chain | 153.2 | 95.3 | 39 | 64 | 32 | 25.4 | 42.3 | 15 | 28 | 5 | 515 | 16.9 |

| 998 Chain | 229.4 | 95.3 | 39.7 | 67.6 | 30.2 | 25.4 | 41.7 | 15 | 28.6 | 5 | 605 | 14.8 |

| 9118 Chain | 229.4 | 125 | 50 | 78 | 37.2 | 33.5 | 52 | 20 | 35 | 5 | 832 | 24.2 |

| 80 Chain | 80 | 48 | 18.8 | 29 | 13.5 | 13 | 21 | 6.5 | 12 | 6.5 | 110 | 3.2 |

| 80H Chain | 80 | 72 | 32 | 42 | 19.5 | 19 | 34.5 | 11 | 18 | 6.5 | 250 | 8.7 |

| XT 100 Chain | 100 | 58 | 25 | 37 | 17.4 | 16 | 26.5 | 8.5 | 16 | 9 | 220 | 4.7 |

| XT 160 Chain | 160 | 78 | 34.5 | 54 | 28 | 20.5 | 36 | 12 | 24 | 5 | 410 | 10.3 |

Drop Forged Rivetless Chain Characteristics

Drop forged rivetless chains are specialized conveyor chains widely utilized across different industries. Here are their key features:

- High Strength: Made from high-strength steel, these chains are tough and durable.

- Vertical Flexibility: They can be easily bent vertically, making them suitable for inclines, curves, and changes in elevation.

- Increased Load Capacity: With higher tensile strength than other conveyor chains, they can carry greater loads.

- Easy Maintenance: These chains are lubrication-free and maintenance-free, minimizing downtime and enhancing operational efficiency.

- Korrosionsbeständigkeit: Their excellent corrosion resistance makes them ideal for harsh environments exposed to corrosive elements.

- Easy Replacement: The design allows for simple replacement of individual links, reducing downtime and maintenance costs.

- Versatility: They are applicable in various sectors, including material handling, automotive, and food processing.

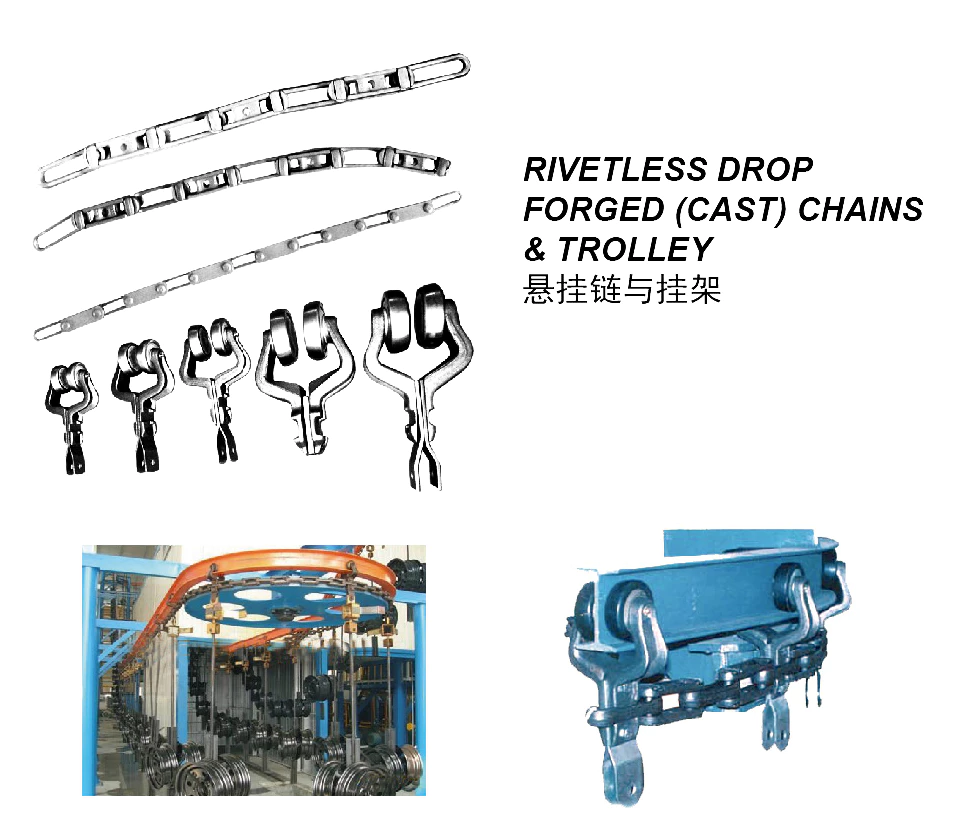

Drop Forged Rivetless Chain Applications

Drop forged rivetless chain is a robust conveyor chain widely utilized in various industrial applications due to its durability. Here are some key applications:

- Material Handling: These chains are used in conveyor systems to transport heavy items like pallets, crates, and containers, capable of withstanding the stresses of heavy-duty operations.

- Automotive Manufacturing: In the automotive sector, they are employed in paint shops, body shops, and assembly lines, handling high temperatures, harsh chemicals, and significant loads.

- Food Processing: Made from stainless steel, drop forged rivetless chains are used to convey food products like meat and seafood, ensuring compliance with food safety regulations to prevent contamination.

- Paper Manufacturing: In paper mills, these chains transport large rolls of paper during production processes.

- Agriculture: They are also found in agriculture, conveying grain, feed, and fertilizer while enduring outdoor conditions such as dust and moisture.

- Mining: The mining industry relies on these chains for both underground and surface operations, designed to handle extreme loads and harsh environments.

Drop forged rivetless chains are essential in various industries for their strength, durability, and capacity to manage heavy loads in demanding applications.

Sprockets for Gesenkgeschmiedete, nietenlose Kette

Drop forged rivetless chain sprockets are essential components in material handling systems, designed to transfer heavy loads both horizontally and vertically. Made from high-quality steel, these sprockets feature a solid, one-piece construction that ensures outstanding strength and durability. Their rivetless design facilitates easy installation and maintenance without the need for special tools. Each sprocket is fitted with a tooth profile tailored to the chain size, maximizing engagement and power transfer.

Typically used alongside drop forged rivetless chains, which have an interlocking design for smooth operation, these sprockets are commonly found in overhead conveyor systems, storage solutions, and various material handling equipment. Overall, drop forged rivetless chain sprockets provide a reliable and efficient solution for heavy-duty material handling tasks.

|

|

Über uns

RP Techniek BV is the Dutch sales agent for Ever-power Group, a globally recognized leader in manufacturing high-quality power transmission and conveyor components. Ever-power Group specializes in producing durable and efficient products tailored to meet the diverse needs of various industries.

We are a leading supplier of drop forged rivetless chains, including various types such as drop forged chains, conveyor chains, and detachable chains like X348, X458, X678, and X698. Our products can be tailored to your specifications, whether based on your drawings or samples. We offer high-quality options made from materials like 40Cr, 20CrMnTi, and 42CrMo to meet your requirements.

Our range includes extended pin chains and pushers to accommodate diverse customer needs, and we also manufacture special chains, pins, and plates as requested. With over 90% of our products exported to markets including the USA, Canada, Japan, Korea, Brazil, and Australia, we are committed to providing competitive pricing and excellent service. Please share your detailed inquiries, and we’ll respond promptly with our best offer.

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...