In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Technische Daten

Here are the parameters of the C60 Combination Chain:

| Chain No. | Pitch In Inches | Per Weight Foot Lbs | Average Ultimate Strength Lbs. | Maximum Working Load Lbs. | A | C | D | E | F | H | N | T | X | Available Attachments |

| C 55 | 1.631 | 2.20 | 9000 | 1400 | 0.69 | 2.06 | 0.375 | 1.97 | 0.75 | 0.72 | ¡ª | 0.19 | 1.25 | A22,G19,F30,K1 |

| C 55L | 1.631 | 2.50 | 11000 | 1400 | 0.69 | 2.06 | 0.375 | 1.97 | 0.75 | 0.72 | ¡ª | 0.19 | 1.25 | None |

| C 60 | 2307.000 | 3.00 | 16000 | 2620 | 0.88 | 2.94 | 0.500 | 2.88 | 1.00 | 0.75 | ¡ª | 0.25 | 1.69 | None |

| C 77 | 2.308 | 2.30 | 11000 | 1640 | 0.69 | 2.38 | 0.437 | 2.25 | 0.88 | 0.72 | ¡ª | 0.19 | 1.25 | F2 K1 |

| C 188 | 2.609 | 3.65 | 14000 | 2350 | 0.94 | 2.69 | 0.500 | 2.50 | 1.12 | 0.88 | ¡ª | 0.25 | 1.56 | F2,G6,K1,K2,S1,G19 |

| BRH 188 | 2.609 | 4.80 | 14000 | 2350 | 0.94 | 2.69 | 0.500 | 2.50 | 1.12 | 0.88 | 3.12 | 0.25 | 1.56 | None |

| C 131 | 3.075 | 6.65 | 24000 | 3880 | 1.12 | 3.75 | 0.625 | 3.50 | 1.50 | 1.22 | ¡ª | 0.38 | 2.06 | F2,G6,K2 |

| C 102B | 4.000 | 6.75 | 24000 | 5400 | 2.00 | 4.56 | 0.625 | 4.38 | 1.50 | 0.97 | ¡ª | 0.38 | 2.91 | K2 |

| C 1021/2 | 4.040 | 9.50 | 38600 | 6530 | 2.00 | 5.00 | 0.750 | 4.38 | 1.75 | 1.38 | ¡ª | 0.38 | 2.91 | K2,S1 |

| C 11 | 4.760 | 9.80 | 36000 | 7590 | 2.38 | 5.44 | 0.750 | 5.00 | 1.75 | 1.44 | ¡ª | 0.38 | 3.38 | K2,S1 |

| C111C | 4.760 | 9.40 | 45000 | 7590 | 2.38 | 5.44 | 0.750 | 5.00 | 1.75 | 1.44 | ¡ª | 0.38 | 3.38 | K2,S1 |

| C110 | 6.000 | 6.20 | 24000 | 5380 | 1.94 | 4.56 | 0.625 | 4.38 | 1.50 | 1.25 | ¡ª | 0.38 | 2.88 | K2 |

| C133 | 6.000 | 8.80 | 36000 | 5900 | 1.25 | 4.31 | 0.875 | 4.00 | 2.00 | 1.75 | ¡ª | 0.38 | 2.88 | None |

| C132 | 6.050 | 14.50 | 50000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | ¡ª | 0.5 | 4.31 | K2,F4,F10,AM116 |

| PW132 | 6.050 | 16.10 | 65000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | 5.88 | 0.5 | 4.31 | S1 |

| MBP132 | 6.050 | 15.70 | 65000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | 5.88 | 0.5 | 4.31 | S1 |

| MBP132C | 6.050 | 15.70 | 65000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | 5.88 | 0.5 | 4.31 | S1 |

Einführung

When it comes to heavy-duty industrial applications, you need a chain that can handle the toughest environments. That's where the C60 Combination Chain comes in. This chain is engineered to provide the ultimate in strength and durability for demanding applications in mining, construction, and other heavy industries.

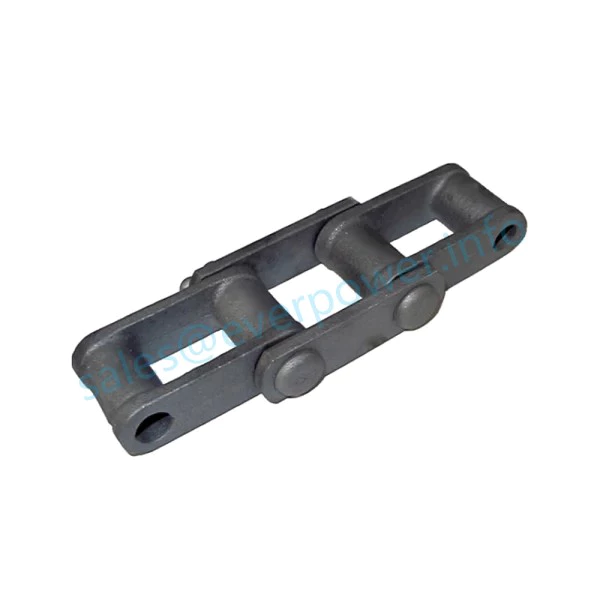

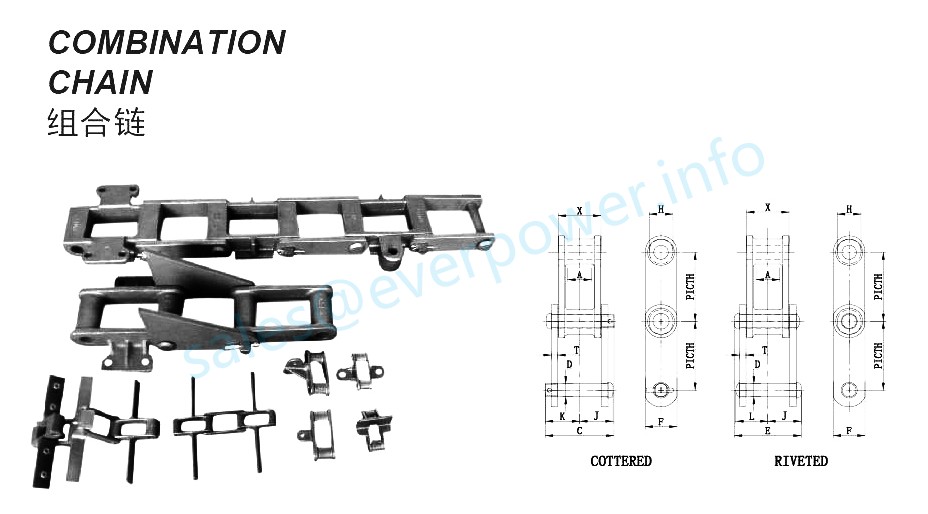

Design

The C60 Combination Chain is made from high-quality steel, which is heat-treated and hardened for maximum durability. Its unique design features a combination of link styles, including straight and bent links, which provide increased flexibility and resistance to fatigue. The chain also features specially designed pins and bushes, which provide maximum wear resistance and reduce the risk of elongation over time.

Technische Daten

The C60 Combination Chain is available in a variety of sizes and configurations to meet the needs of any heavy-duty application. It comes in a range of pitch sizes, from 1 inch to 3 inches, and is available in both standard and heavy-duty versions. The chain is also available in a variety of finishes, including black oxide, zinc-plated, and nickel-plated.

Applications

The C60 Combination Chain is designed to handle the toughest industrial applications, including mining, construction, and heavy machinery. Its strength and durability make it ideal for use in conveyor systems, hoists and cranes, and other heavy-duty equipment. The chain is also suitable for use in high-temperature environments, making it ideal for use in manufacturing and other industrial processes.

Maintenance

To ensure maximum performance and longevity, it is important to properly maintain your C60 Combination Chain. Regular lubrication is essential to prevent wear and reduce friction, which can cause damage to the chain over time. It is also important to regularly inspect the chain for signs of wear or damage, and to replace any damaged components as soon as possible.

Conclusion

The C60 Combination Chain is the ultimate in strength and durability for heavy-duty industrial applications. Its unique design, high-quality materials, and rigorous manufacturing standards ensure that this chain will perform reliably for years to come. If you're looking for a chain that can handle the toughest environments, look no further than the C60 Combination Chain.

Choose Our Malleable Casting Chains

RP Techniek BV, the Netherlands sales agent of Ever-power Group, is proud to present our high-quality malleable casting chains. With the inclusion of the C60 Combination Chain, we emphasize the unique selling points of our malleable cast iron chains, highlighting their exceptional product quality and outstanding services. Our strong manufacturing capabilities further ensure customer satisfaction.

In addition to our malleable casting chains, we also offer a wide range of other types of casting chains. Our diverse selection caters to various needs and requirements, ensuring that customers can find the perfect chain for their specific applications.

At RP Techniek BV, we are committed to providing top-notch products and excellent customer service. Choose our malleable casting chains for superior quality and reliability. Contact us today to learn more about our extensive range of casting chains and how we can fulfill your chain needs.

Sprockets for Sale

When it comes to finding the right chain sprockets for your machinery, it's important to choose a product that is durable, reliable, and efficient. The C60 combination chain is a popular choice for many industries, and it requires the right type of sprockets to operate at peak performance. At our company, we offer a wide range of chain sprockets to suit your unique needs and preferences. From standard sizes to custom designs, we have it all.

Our sprockets are made from high-quality materials and are designed to withstand heavy loads and frequent use. We understand that every industry is different, which is why we offer a variety of sprocket types, including single, double, and triple strand sprockets, as well as taper lock sprockets and conveyor sprockets. No matter what type of machinery you need sprockets for, we've got you covered.

With our commitment to quality and customer satisfaction, you can trust that our sprockets are the best choice for your business. We offer competitive prices and fast shipping, so you can get the products you need quickly and affordably. Don't settle for subpar sprockets - choose our company for all your chain sprocket needs.

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...