In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications for 501CSS Stainless Steel Hollow Pin Chain

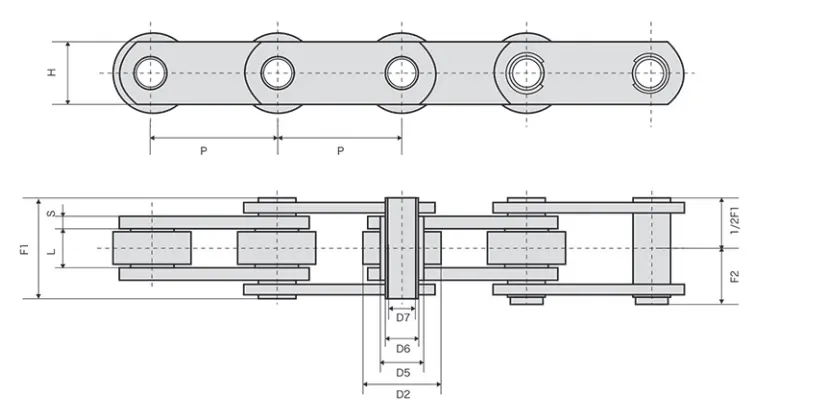

Here are the parameters for the 501CSS Stainless Steel Hollow Pin Chain:

| Chain No. |

P(mm) | L(mm) | D2(mm) | D5(mm) | D6(mm) | D7(mm) | H(mm) | S(mm) | F1(mm) | F2(mm) | Breaking(Load N) | Weight(kg/m) |

| 250RSS | 50 | 11,5 | 25 | 11 | 9 | 6.2 | 20 | 2.5 | 25 | 14 | 38 | 1.8 |

| 250SS | 50 | 11.5 | 25 | 11 | 9 | 6.2 | 20 | 2.5 | 25 | 14 | 25 | 1.8 |

| 400CSS* | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 3 | 31 | 17 | 35 | 3 |

| W3635SS | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 3 | 31 | 17 | 35 | 3 |

| 500CRPSS | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 18.5 | 65 | 3.6 |

| 500CSS* | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 20 | 40 | 3.6 |

| 501CSS | 75 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 20 | 40 | 3.1 |

| 502CSS | 100 | 15 | 31 | 17 | 14 | 10,2 | 25 | 4 | 35 | 20 | 40 | 2.6 |

| 503CSS | 125 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 18.5 | 40 | 2.4 |

| 503CSS | 125 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 20 | 40 | 2.4 |

| 504CSS | 150 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 18.5 | 40 | 2.3 |

| 701CSS | 75 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 5.4 |

| 703CSS | 100 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 4.4 |

| 703CRSS | 100 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 75 | 0.4 |

| 704CSS | 125 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 4.2 |

| 704CRSS | 125 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 75 | 4.2 |

| 705CSS | 150 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 4 |

| 705CRSS | 150 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 75 | 4 |

501CSS Stainless Steel Hollow Pin Chain

1. Introduction

The 501CSS Stainless Steel Hollow Pin Chain is a high-quality chain designed for various industrial applications. With its unique features and durability, this chain offers exceptional performance and reliability in demanding environments.

2. Construction

The 501CSS chain is constructed using premium-grade stainless steel material, ensuring excellent corrosion resistance and prolonged lifespan. It features hollow pins, which offer reduced weight without compromising strength and durability. The precision engineering of this chain guarantees smooth operation and efficient power transmission.

3. Applications

This chain is widely used in industries such as food processing, pharmaceuticals, packaging, and more. Its stainless steel construction makes it ideal for environments with high humidity, chemicals, or extreme temperatures. The 501CSS chain can handle heavy loads and is suitable for conveying, driving, and lifting applications.

4. Key Features

- Korrosionsbeständigkeit: The stainless steel material provides excellent resistance to rust, chemicals, and other corrosive substances.

- Hollow Pin Design: The hollow pins reduce the overall weight of the chain while maintaining its strength.

- Precision Engineering: The chain is manufactured with precision to ensure smooth operation and minimal power loss.

- High Load Capacity: The 501CSS chain can handle heavy loads, making it suitable for demanding industrial applications.

- Versatility: This chain is suitable for various applications, including conveying, driving, and lifting.

5. Benefits

By choosing the 501CSS Stainless Steel Hollow Pin Chain, you can enjoy numerous benefits:

- Long-lasting performance due to its corrosion-resistant stainless steel construction.

- Reduced maintenance requirements thanks to its durable design.

- Improved efficiency and power transmission with its precision engineering.

- Enhanced safety with its high load capacity and reliable operation.

- Wide range of applications, making it a versatile solution for various industries.

Invest in the 501CSS Stainless Steel Hollow Pin Chain for your industrial needs and experience the reliability and durability it offers. Contact us today to learn more about this exceptional chain and how it can benefit your operations.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the sales representative of Ever-power Group in the Netherlands. We take pride in offering the exceptional 501CSS Stainless Steel Hollow Pin Chain, which embodies our unique selling points. Our stainless steel chains stand out for their superior quality, durability, and reliability.

At RP Techniek BV, we understand the importance of meeting our customers' needs. Therefore, we provide a wide range of other stainless steel roller chains in addition to the 501CSS, ensuring that we have the perfect solution for every application. Whether you require a standard chain or a customized design, we have the expertise to deliver.

With our state-of-the-art production facilities, we guarantee the highest level of manufacturing excellence. Our dedicated team of professionals ensures that each chain meets rigorous quality standards, providing you with a product that will perform flawlessly even in demanding environments.

Choose RP Techniek BV for unmatched stainless steel roller chains that offer exceptional performance and longevity. Contact us now to discuss your requirements and experience the difference we can make in your operations.

Sprockets for Sale

Looking for the perfect sprocket to pair with your 501CSS Stainless Steel Hollow Pin Chain? Look no further than our selection of high-quality sprockets.

At our company, we offer a wide variety of sprockets to fit any need. From standard pitch to double pitch, from hardened steel to stainless steel, we have the right sprocket for your application. Our sprockets are made from top-quality materials and are precision manufactured to ensure a perfect fit with your chain.

Whether you need a sprocket for a conveyor, a machine, or any other application, we have you covered. Our knowledgeable staff can help you choose the right sprocket for your needs and answer any questions you may have.

So why wait? Contact us today to learn more about our selection of sprockets and find the perfect match for your 501CSS Stainless Steel Hollow Pin Chain.

Weitere Informationen

| Editor | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...