In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

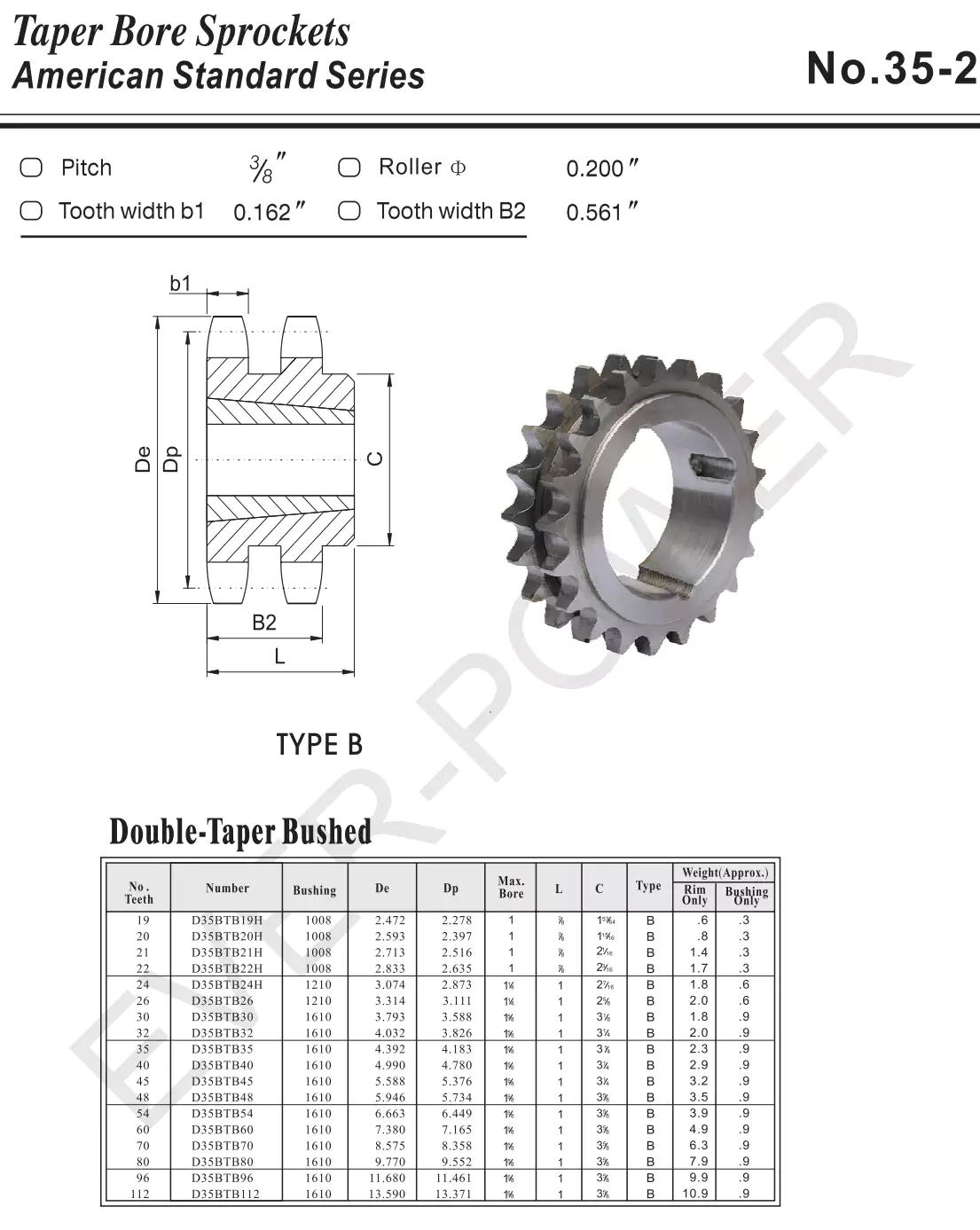

#35-2 3/8″ Taper Bore Sprocket

The #35-2 3/8″ Taper Bore Sprocket is designed for efficient power transmission in various machinery applications. Crafted from high-quality materials, it ensures durability and reliability. Its taper bore feature allows for easy installation and adjustment, making it an ideal choice for enhancing performance in conveyor systems and other industrial equipment.

#35-2 3/8" Taper Bore Sprocket Specifications

The #35-2 3/8" Taper Bore Sprocket is a specialized component designed for efficient power transmission in various mechanical systems. This sprocket features a taper lock bushing, which simplifies the installation and removal process, making it user-friendly for maintenance and adjustments. Due to its reliability and minimal maintenance requirements, this sprocket has found applications in numerous industries where consistent performance is crucial.

Characteristics and Functions of Taper Bore Sprocket

- Easy Installation: The taper lock design facilitates a rapid and straightforward installation process of the sprocket onto the shaft, enhancing efficiency.

- High Precision Positioning: This unique locking mechanism ensures accurate placement of the sprocket, minimizing the risk of misalignment, and significantly boosting overall system performance.

- Wide Applicability: The Taper Bore Sprocket is adaptable, making it ideal for a range of power transmission tasks, including those in machinery, conveyor systems, and extensive industrial equipment.

- Reliability: With a robust construction and secure locking feature, this sprocket provides consistent and efficient power transmission, meeting demanding operational needs.

- Low Maintenance Cost: The design of the Taper Bore Sprocket requires minimal upkeep, resulting in reduced operating costs and improved long-term value.

Installation and Removal Process of Taper Bore Sprocket

- Prepare Tools and Materials: Gather all required tools and materials, including the taper lock bushing, sprocket, and locking nut to ensure a smooth installation process.

- Clean Shaft and Sprocket Surface: It is critical to clean both the shaft and sprocket surfaces thoroughly, ensuring they are free from any dirt, debris, or contaminants to guarantee a secure connection.

- Place Taper Lock Bushing: Carefully slide the taper lock bushing onto the shaft, making sure it is positioned correctly for optimal performance.

- Install Sprocket: Align the sprocket with the taper lock bushing, ensuring the holes correspond with the locking pins of the bushing for a secure fit.

- Tighten Locking Nut: Use the appropriate tools to securely tighten the locking nut, firmly holding the sprocket in place for reliable operation.

Manufacturing Process of Taper Bore Sprocket

- Raw Material Preparation: Choose high-quality steel or other suitable materials necessary for the manufacturing process to ensure durability and strength.

- Cutting: Cut the raw materials into precise shapes and sizes required for further processing to meet product specifications.

- Forging or Casting: Depending on the desired outcomes, the sprocket can undergo forging or casting processes to achieve optimal strength and durability.

- Machining: Employ advanced machining techniques to refine the dimensions of the sprocket and create accurate teeth or cogs.

- Rolling: The teeth or cogs are rolled onto the sprocket, enhancing their strength and ensuring smooth interaction with the chain.

- Heat Treatment: Subject the sprocket to heat treatment processes to increase hardness and toughness, enhancing overall functionality and longevity.

- Surface Treatment: Apply protective surface treatments, such as coatings or plating, to guard against corrosion and wear, prolonging the sprocket's life.

- Quality Inspection: Conduct comprehensive quality checks to ensure that the sprocket meets all established specifications and industry standards.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group, a prominent manufacturer within the power transmission sector. We offer a diverse range of high-quality sprockets, including the #35-2 3/8" Taper Bore Sprocket. This product is engineered for durability and operational efficiency, ensuring it performs optimally across various applications. Our sprockets are produced from premium materials, ensuring resilience under rigorous usage while delivering dependable service.

In addition to our standard offerings, we specialize in providing custom solutions tailored to meet the unique specifications of our customers. Whether you require a specific design or dimensions, we encourage clients to present their drawings and samples for bespoke production. Our dedicated team is committed to delivering exceptional service and high-quality products to fulfill your requirements.

Weitere Informationen

| Edited | Zqq |

|---|

Blogs aktualisiert

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...