Einführung

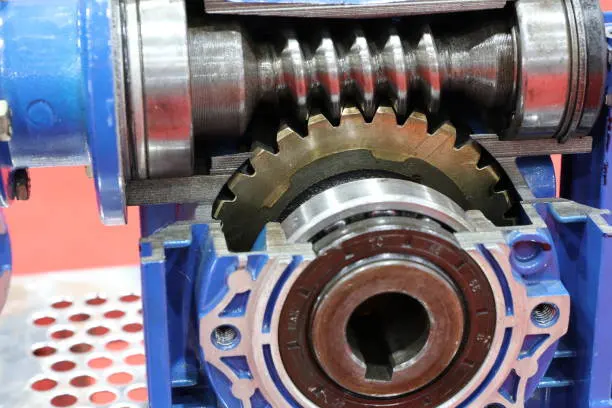

The EPRV series small worm gearboxes are innovative power transmission devices that play a vital role in various industries. These gearboxes are known for their efficiency, durability, and compact design, making them suitable for a wide range of applications. In this article, we will explore the lubrication process for EPRV series small worm gearboxes and delve into its significance in ensuring smooth operation and longevity of the equipment.

Understanding Gearbox Lubrication

Gearbox lubrication is a crucial aspect of maintaining the performance and extending the lifespan of EPRV series small worm gearboxes. Proper lubrication ensures reduced friction, heat, and wear, allowing the gears to operate smoothly and efficiently. Let’s delve into the lubrication process and its essential components:

1. Lubricant Selection

Selecting the right lubricant is paramount for optimal gearbox performance. The EPRV series small worm gearboxes require high-quality lubricants with excellent thermal stability, anti-wear properties, and corrosion resistance. Synthetic oils or semi-fluid greases are typically used for lubricating these gearboxes.

2. Lubrication Method

The lubrication method employed for EPRV series small worm gearboxes is the oil bath lubrication system. This method involves immersing the gears and bearings in oil to ensure proper lubrication and cooling. The oil level is set to cover the worm gears and half-submerge the worm wheel, allowing for effective lubrication during operation.

Advantages of Proper Lubrication

Proper lubrication of EPRV series small worm gearboxes offers several advantages:

1. Increased Efficiency

Effective lubrication reduces friction and heat generation, resulting in improved gearbox efficiency. This allows for smooth power transmission and minimizes energy losses.

2. Enhanced Durability

By reducing wear and tear, proper lubrication extends the lifespan of the EPRV series small worm gearboxes. It ensures the gears and bearings operate within their optimal limits, preventing premature failure.

3. Noise Reduction

Well-lubricated gearboxes produce less noise during operation. The lubricant acts as a cushion between the gear teeth, dampening vibrations and minimizing noise levels.

Elektromotoren zu verkaufen

The relationship between gearboxes and electric motors is symbiotic. Gearboxes, such as the EPRV series small worm gearboxes, efficiently transmit power from the motor to various applications. They provide the necessary torque amplification, speed reduction, and precise motion control. To complement our gearboxes, our company also offers a wide range of electric motors for sale.

Über uns

RP Techniek BV, the Dutch sales agent for Ever-power Group, is a leading transmission equipment manufacturer with a strong presence in Europe and America. We specialize in the design, production, and sales of high-quality gearboxes for over 25 years. Our company is known for its commitment to delivering superior products, competitive prices, and outstanding customer service.

Our state-of-the-art manufacturing facilities, combined with a team of industry professionals and technicians, enable us to meet the diverse needs of our clients. We serve various industries, including equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, and solar energy industry.

Q&A

1. How often should the lubricant be changed in EPRV series small worm gearboxes?

Lubricant change intervals depend on several factors, including operating conditions and usage. Generally, it is recommended to change the lubricant every 3,000-5,000 hours of operation or as specified by the manufacturer.

2. Can I use any type of lubricant for EPRV series small worm gearboxes?

No, it is essential to use lubricants specifically designed for worm gears. These lubricants have additives that provide the necessary protection against wear and corrosion, ensuring optimum gearbox performance.

3. How can I check the oil level in the gearbox?

Most EPRV series small worm gearboxes are equipped with an oil sight glass or an oil level indicator. These features allow for easy monitoring of the oil level. It is important to ensure the oil level remains within the recommended range.

4. What are the common signs of insufficient lubrication in a gearbox?

Common signs of insufficient lubrication include increased noise, elevated operating temperatures, increased power consumption, and premature gear wear. Regular inspections and maintenance can help identify and address lubrication issues.

5. Can I use grease instead of oil for lubricating EPRV series small worm gearboxes?

Yes, in some cases, semi-fluid greases can be used as an alternative to oil lubrication. However, it is crucial to consult the gearbox manufacturer or refer to the product documentation for specific lubrication recommendations.

Bearbeitet von: Zqq.